Intentionally Presetting a Spring

If a spring is compressed down past the max deflection it can take a set. This is usually a bad thing since it means the spring no longer returns to its original length and can cause problems in the functionality. However, there are some instances in which the spring can be intentionally set or ¨preset¨ so that it actually has the desired length and fulfills the desired travel.

Intentional presetting is used as a last resort when you know the design of a device or space is not really adequately engineered with the spring in mind. Presetting can be done for both compression and torsion springs but it is usually only completed with compression springs so for the sake of this article that is what we will be focusing on.

What is Intentionally Presetting a Spring?

If you know the design is bad or not adequate enough for the proper design of a spring then you need to explore non-conventional options and tricks to see if the spring design can be adjusted for adequate functionality. One of those tricks that a spring engineer can resort to is spring presetting. This is usually the last resort when you spring needs to have a certain distance of travel with the load but the max deflection of the spring does not allow it.

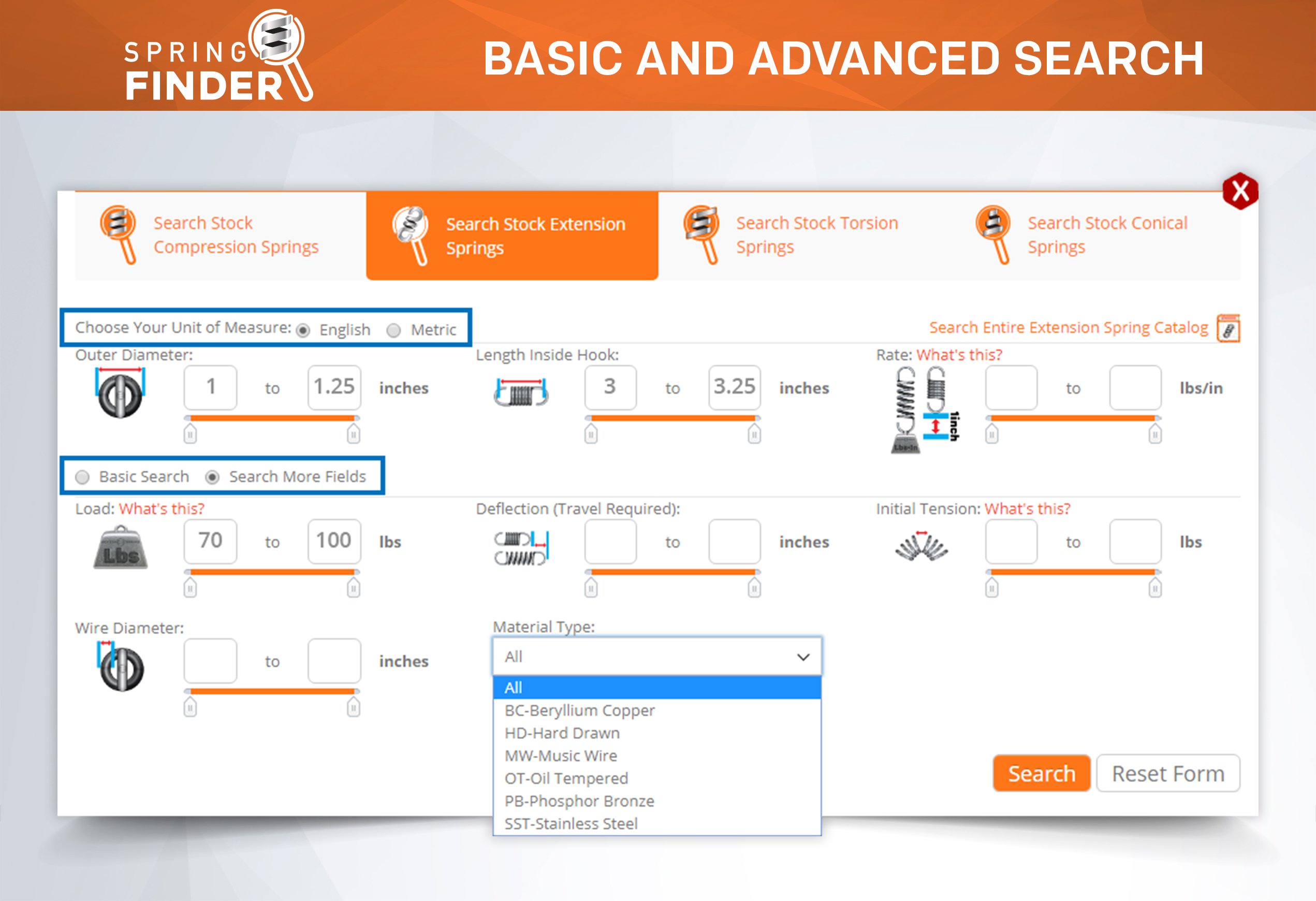

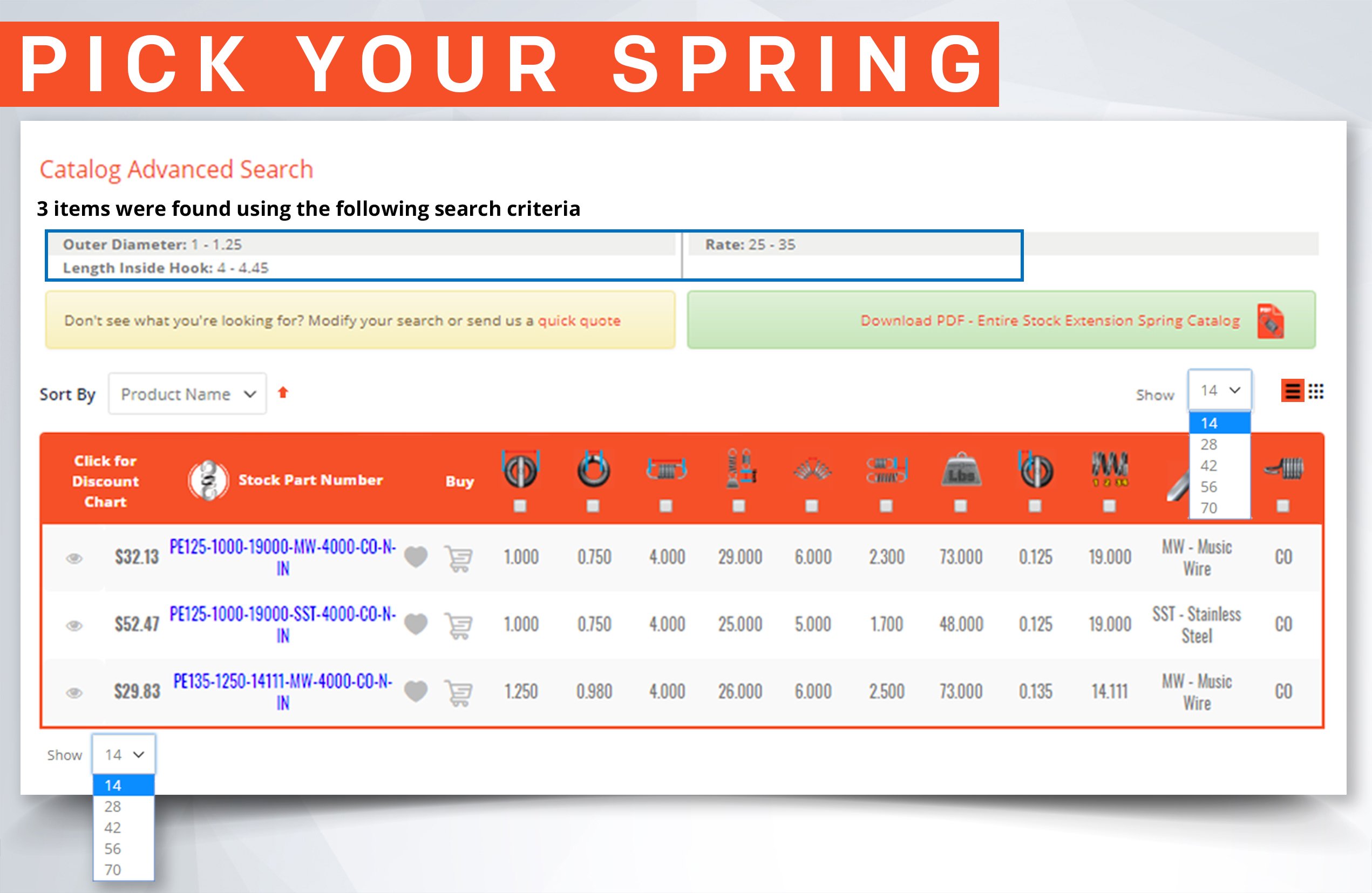

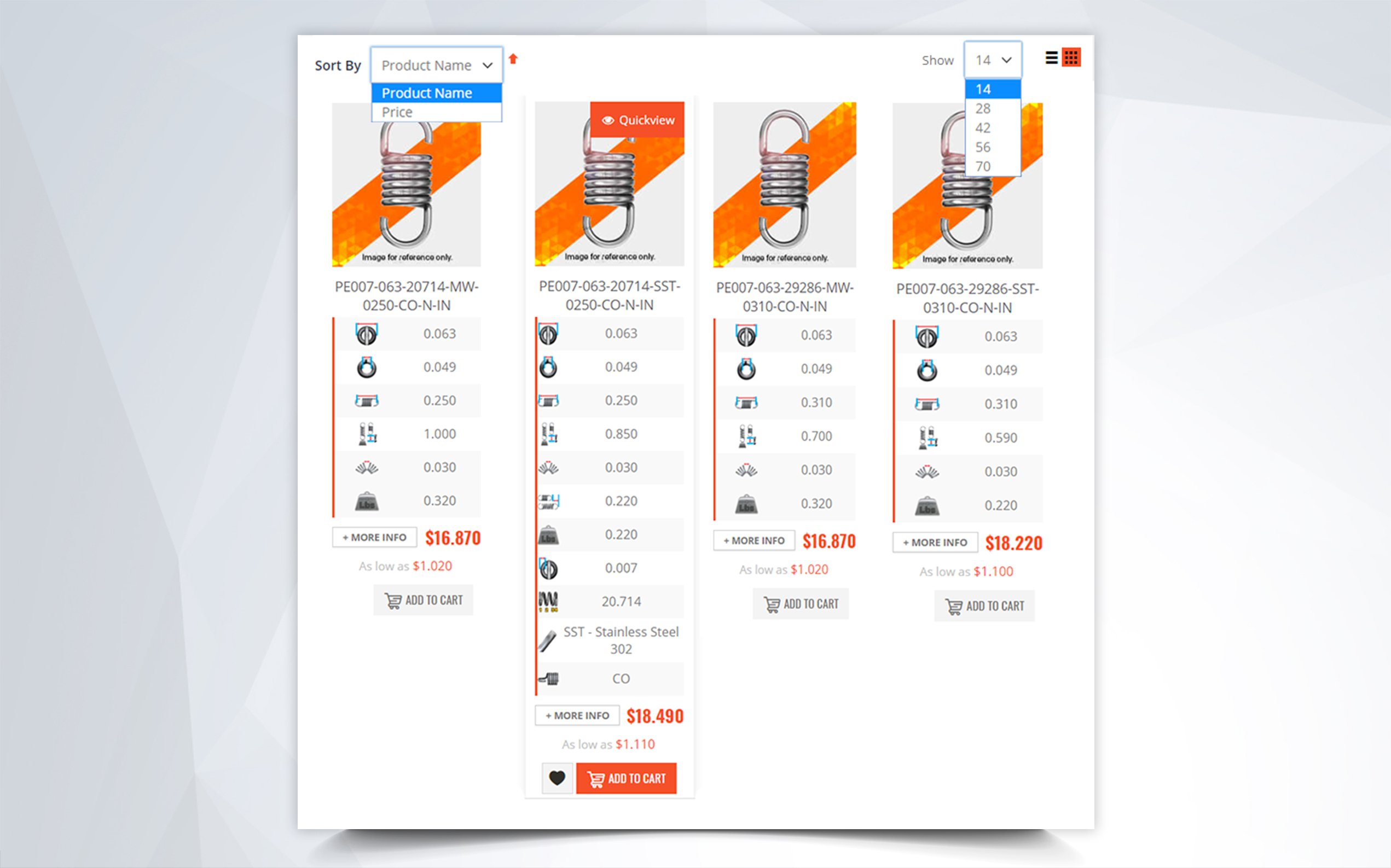

This can be the case for both custom springs as well as stock springs.

When Can Intentional Presetting be an Option?

Presetting for Custom Springs

When making a custom spring it is important for the design of the device to keep into consideration the space and proportions that the spring will need to have. When this doesn’t happen the spring may not be manufacturable or it might require extra adjustments that will increase the difficulty and price of the spring.

Let’s give you an example.

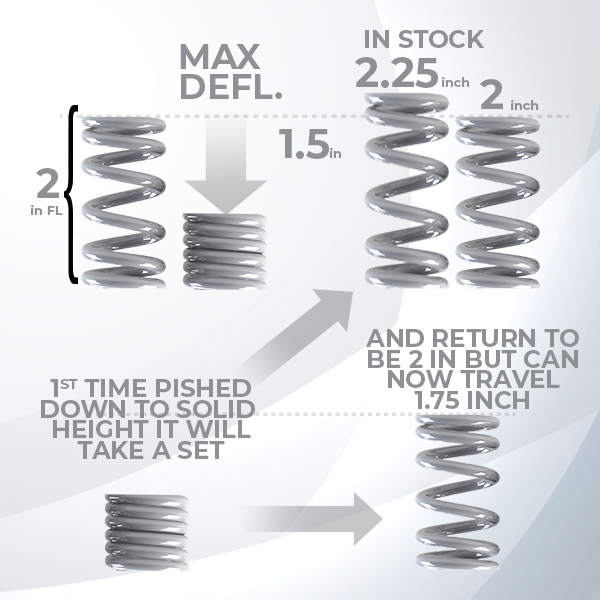

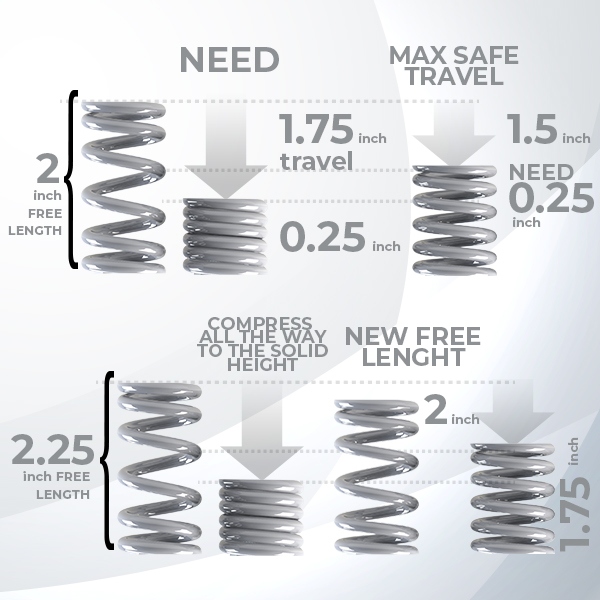

Let’s say you have a two inch long spring and you need an 1.75 inch of travel but the max safe travel is 1.5in even though the solid height is a quarter inch. In theory people think that you would be able to go an 1.75 inch down of travel. Hower if that design does not allow you to go an inch and three quarters. Let’s say it only allows you to go an inch and a half as the max safe travel, and you are a quarter inch away you may be able to pre-set it using reverse engineering. How this works is that instead of manufacturing it to be 2 inches long you would make it 2 ¼ inches long so the difference is ¼ inch in length and then preset it to solid height it would take a set at a ¼ inch and returns to be two inches long and can give you the travel you need. The spring took a set pretty much means that the spring shrunk. However, now you are able to have it travel further down and keep the length at 2 inch.

Presetting a Stock Spring

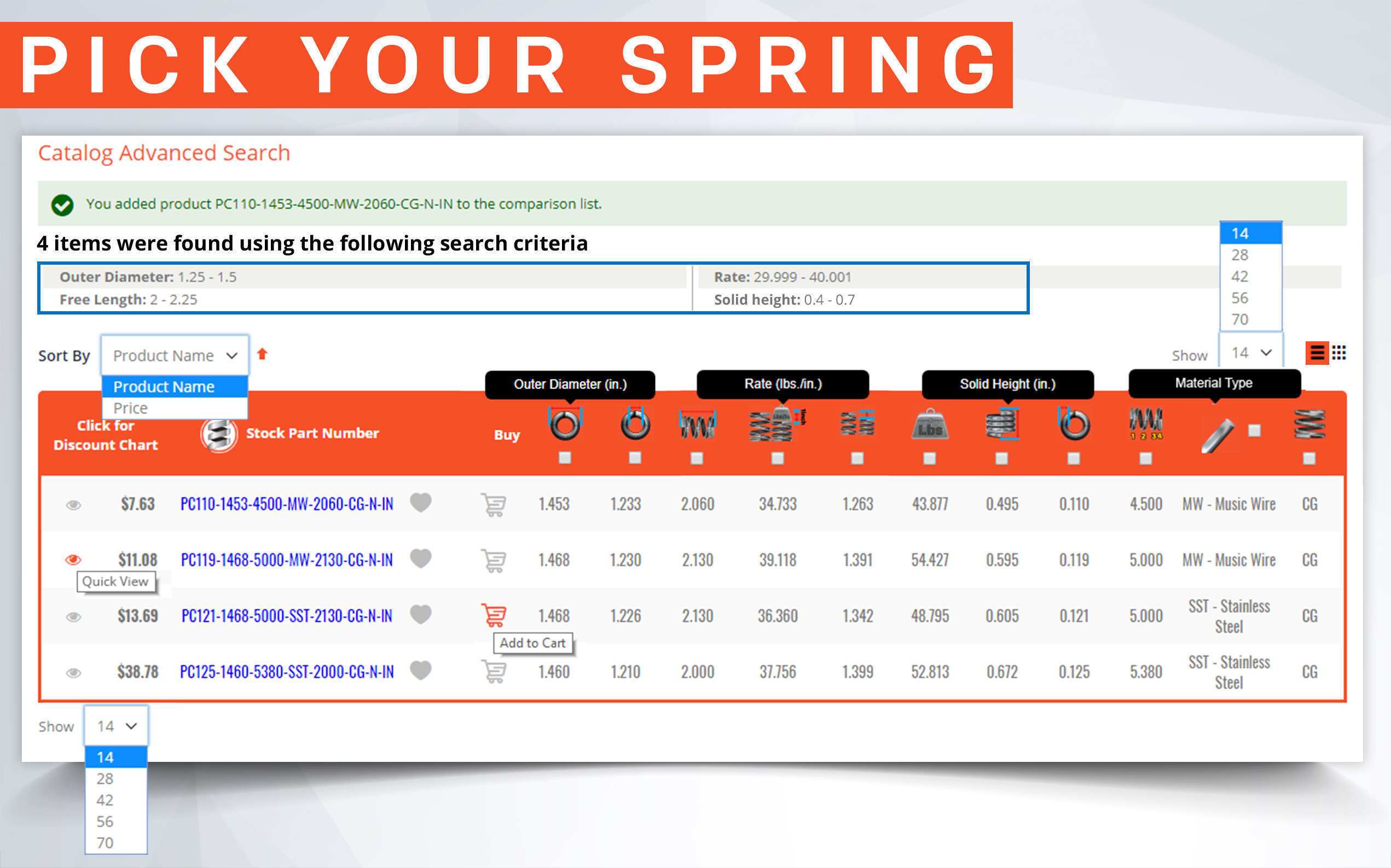

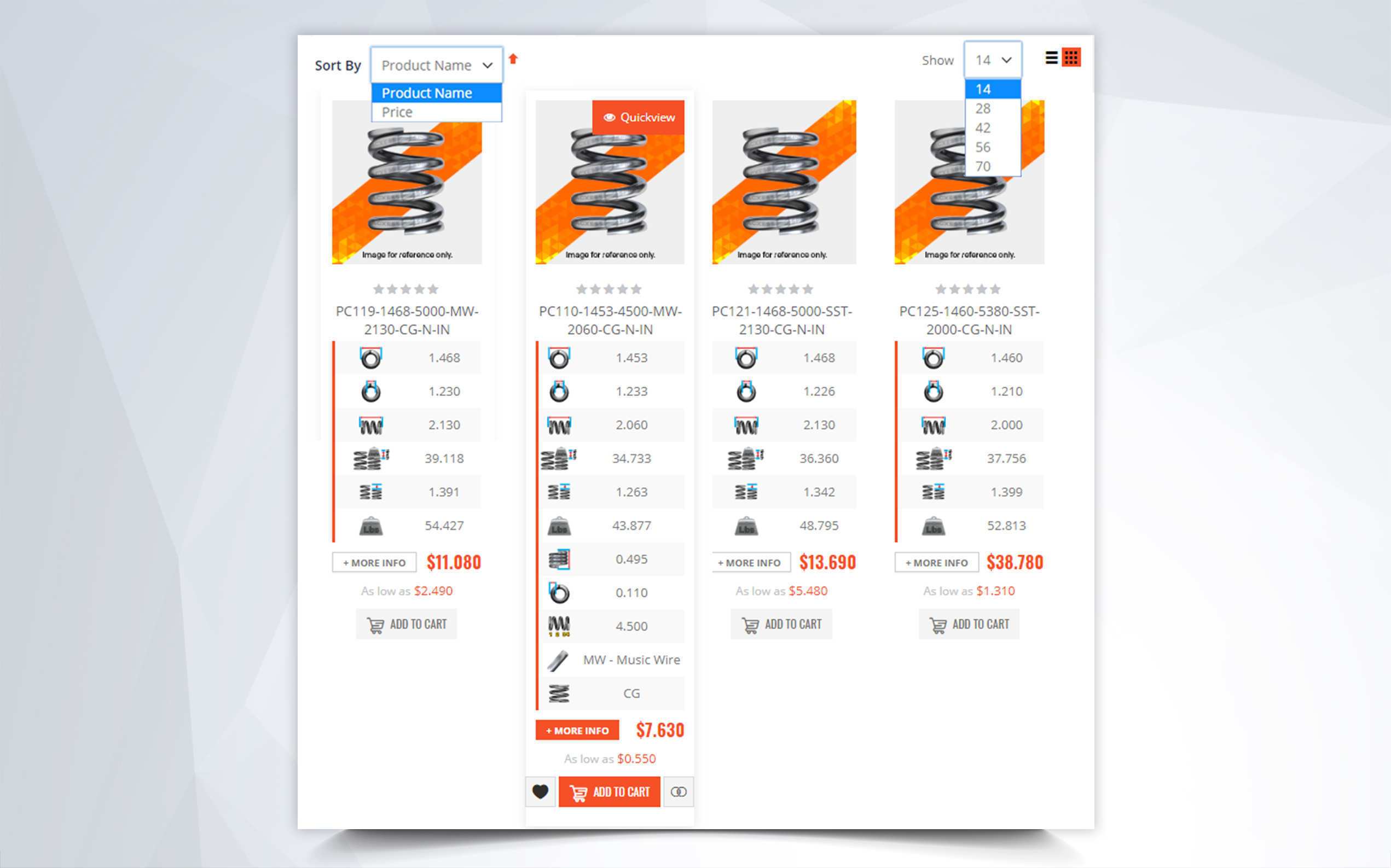

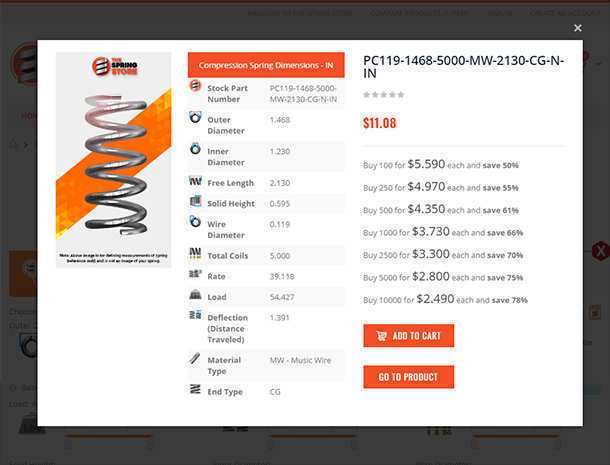

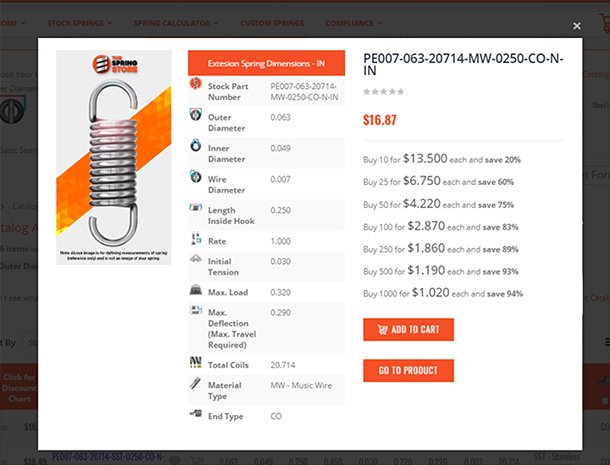

Sometimes a stock spring will meet almost all requirements of a spring but the length or max deflection may be slightly off from what is required. In this case the customer can pay an additional fee to have the stock springs pre-set or order springs that when used will take a preset the first time and after that function as needed without problem. This can be quite useful in many cases and help the customer save a significant amount of time and money instead of having to get a spring designed and custom made.

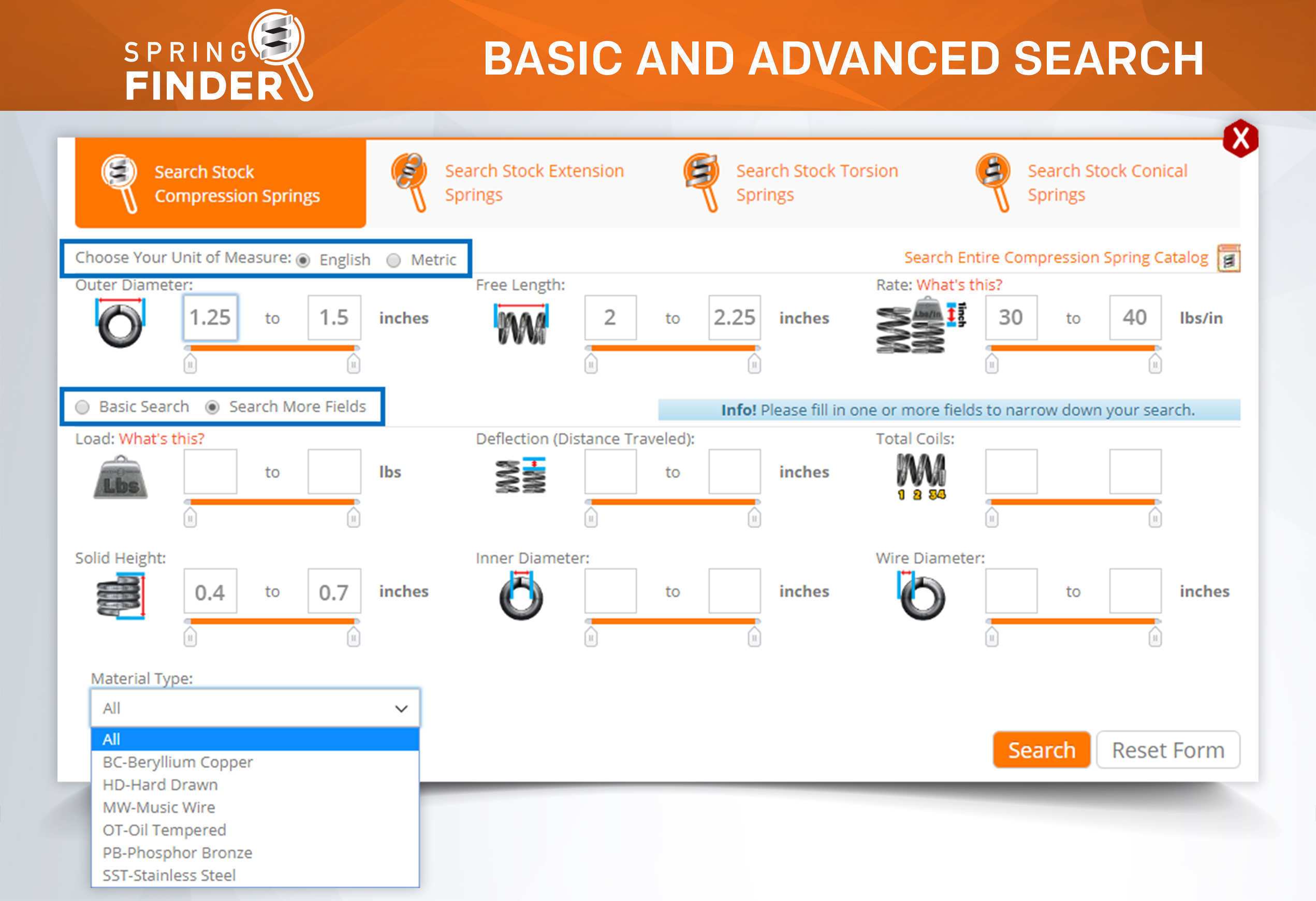

Using the previous example let’s say we have that spring that is 2 inch long but its max deflection is 1.5 and you need it to be 1.75 and let’s say we have the same spring in stock but with a free length of 2.25 inch In that case we would then suggest that you buy the 2.25 in spring so that when you first use that spring as it compresses the first time it will take a set but in the following compressions it will work perfectly. This is an "intended set"