Garter Springs Manufacturers

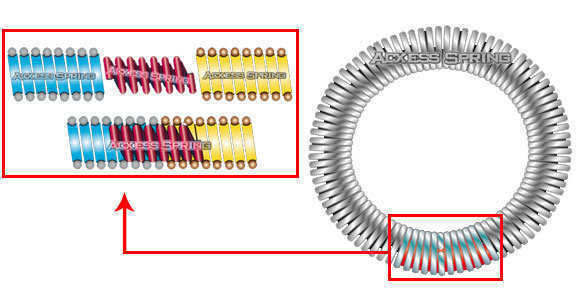

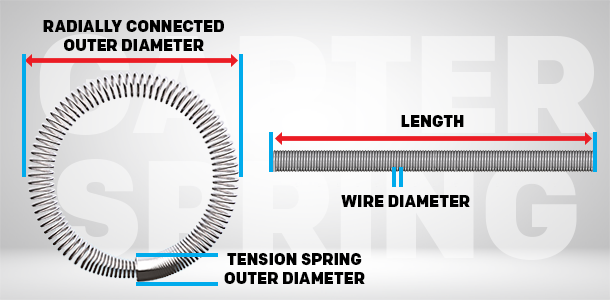

Definition: Garter springs are basically extension springs whose ends are connected to make a garter belt that will exert force from its inner diameter.

Garter springs are regularly used as oil seals or seals in general. They are meant to stabilize the object they’re installed over in changes of temperature or pressure. We, as garter spring manufacturers and suppliers, will make sure to provide you with the garter spring design you need for your applications. They may also be used in other electrical applications. The force they exert is contracting because it contracts into their inner diameter so all angles within the inner diameter are pushing down on the object they’re surrounding. You can always use a regular extension spring but you must make sure that the ends connect to meet your requirements.

There are several types of garter spring connector ends. Some are sturdier than others but the price is also reflected on that.

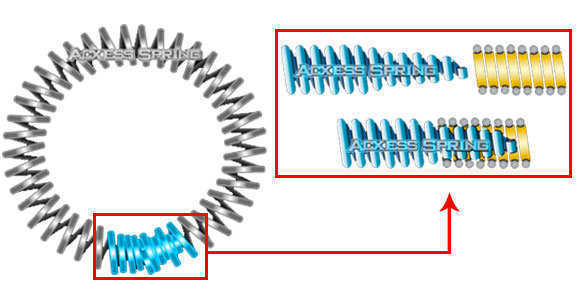

For a simple, economic garter spring, you want to go with a close wound coiled spring with one tapered/conical end. This makes mating parts to assemble your garter spring. The tapered end will be the male part and the regular round end will be the female. To have these made you must make sure that the small diameter of the tapered end doesn’t have a spring index of 4:1 or less.

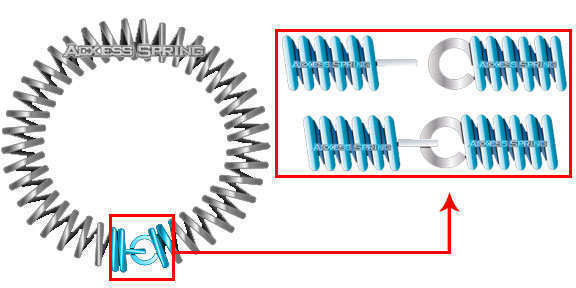

The next common garter spring connector end is the one with the hook end type. You’d be surprised but the thing with closed wound springs hooks is that there is extra manual labor involved to bend the last coils of the close wound coil spring into hooks. Hook ends can be useful if you don’t need a constant seal and you plan to disengage or disassemble the garter spring. Hooks are way easier to disassemble than the rest of the connector end types.

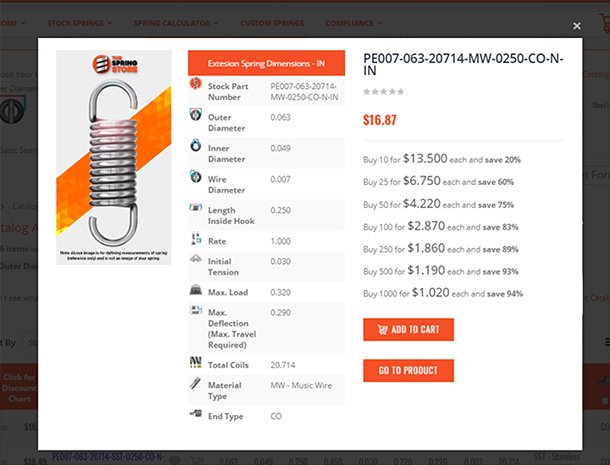

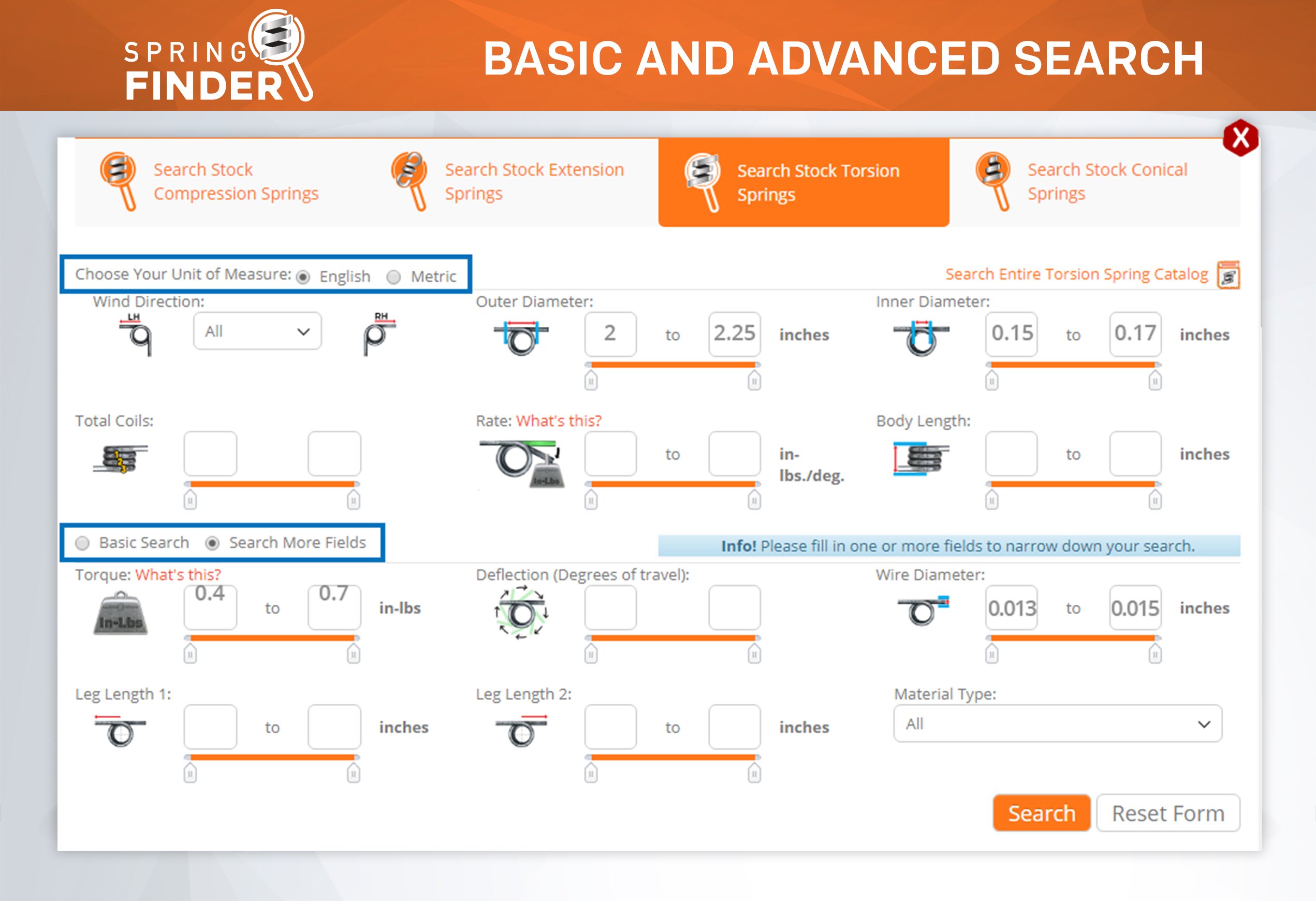

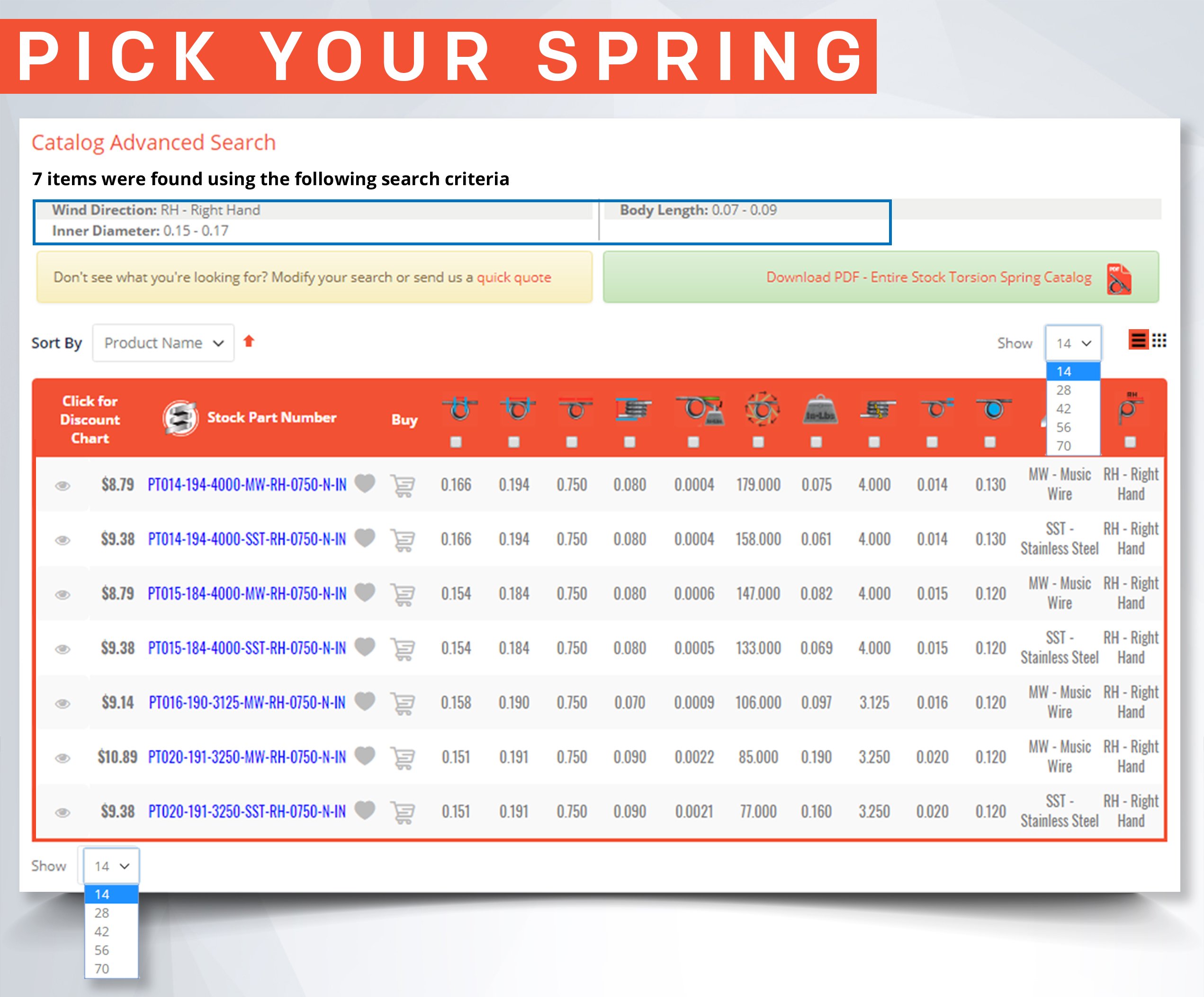

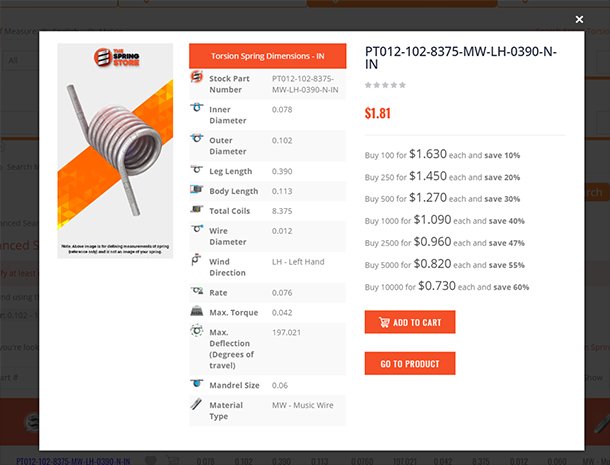

The last common connector involves using a bolt or a smaller spring. This bolt will be inserted and screwed into the inner diameter of both ends. This type of connector end has more grip so the garter spring will hold longer but it will also be a lot more difficult to disassemble so they are recommended for long term use. You can find stock long length extension springs without hooks at The Spring Store for texting an prototypes. Give us a call to get the right extension spring to turn into an effective garter spring.