Coil Torsion Spring Calculator

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Definition: Torsion spring design tool used to calculate the rotational force exerted from its coils; torque is the moment of a force that causes the rotational deflection of its legs.

Use our coil spring torque calculator to calculate your torsion spring's torque values as well as tolerances like maximum deflection and maximum torque. The torque values are based on your torsional spring's rate per degree which is derived from your spring's physical dimensions and material type.

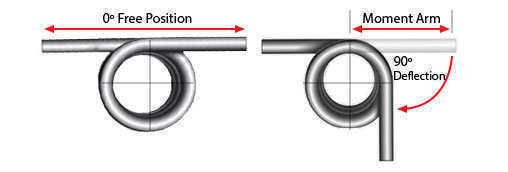

Coil torsion spring torque is easily calculated if you know your spring's rate and one of the torque values; force exerted on spring or degrees of deflection. When you determine the force being applied on your spring, you must consider the length of the moment arm. The moment arm is the torsion spring leg that will be in motion while the other will be stationary. The longer your moment arm is beyond 1” (one inch), the stronger your spring will need to be in order to accomplish the required torque. The formulas to calculate torque are the following.

To Calculate Torque (F):

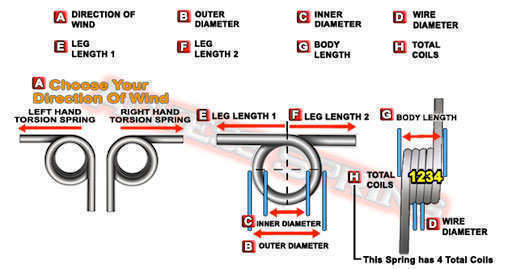

Torque (F) = Moment Arm (M) x Force (P) F = MPHow to Measure Coil Torsion Springs

To Calculate Working Torque (Amount of Force @ Amount of Degrees Traveled)

Formula A.)

Deflection (Deg) = Torque (F) ÷ Rate (k) Deg = F ÷ kFormula B.)

Torque (F) = Rate (k) x Deflection (Deg) F = kDegTorque / Deflection Help Diagram

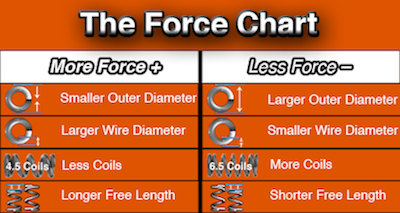

Once you've managed to use these formulas, you might see that maybe you're not meeting either the deflection or torque you're required to meet. By following the provided force chart, you are able to know how you can get your spring to have more or less force. For more force, you may increase the wire diameter, decrease the outer/inner diameter, or take out some coils. For less force, you may decrease the wire diameter, increase the outer/inner diameter, or add some coils. These adjustments will also affect the maximum spring deflection limit, though. The stronger your spring is, the more stressed. This is where you might want to take a look at your spring index which you can calculate by subtracting one wire diameter from the outer diameter (or adding one wire diameter to the inner diameter) and dividing the result (mean diameter) by the wire diameter itself. Spring index is the proportional ratio between your spring's diameter and wire diameter. This specifies the tightness of the coils. The lower the torsion spring index, the tighter the coils thus generating more stress upon the spring. Make sure that you check the spring's limitations and how much it will be able to do for your application before actually getting them manufactured because exceeding these limits may cause your spring to take a permanent set thus losing torque.