Helical Compression Spring Design Calculator

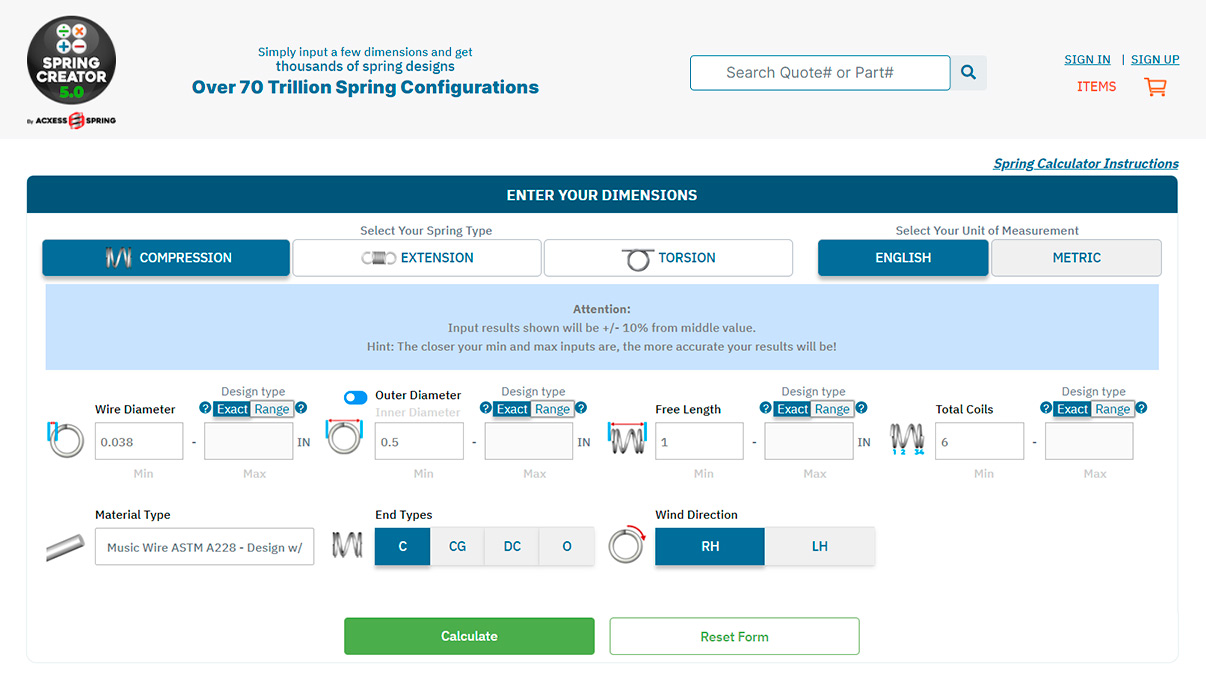

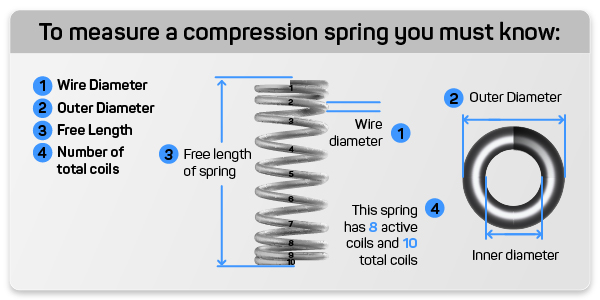

Definition: A helical compression spring design calculator is a spring calculation software which calculates spring rate (or spring constant), safe travel, safe loads, and other important factors using your helical compression spring's physical dimensions like wire diameter, outer diameter, free length, total coils, and material type.

What is a Compression Spring?

Compression springs are helically coiled wires wound one on top of the other to absorb shock or maintain a force between two surfaces. Therefore containing or releasing energy when a load is applied.

Compression springs are used in many devices which serve several different purposes. Therefore, the design of your helical compression spring is very critical when it comes to the force it exerts as well as its physical dimensions. Even the smallest change to a dimension can critically affect the way your spring functions when it comes to spring rate (or spring constant), safe load, and safe travel. For this reason, you must follow certain spring equations or formulas and do various spring calculations when it comes to your compression spring design. This is where our helical compression spring design calculator, "Spring Creator" comes in to avoid you the trouble of calculating all the formulas and equations by hand.

Below you will find all the information you need to design your helical compression spring including formulas, how-to-measure diagrams, and tips from our spring engineers.

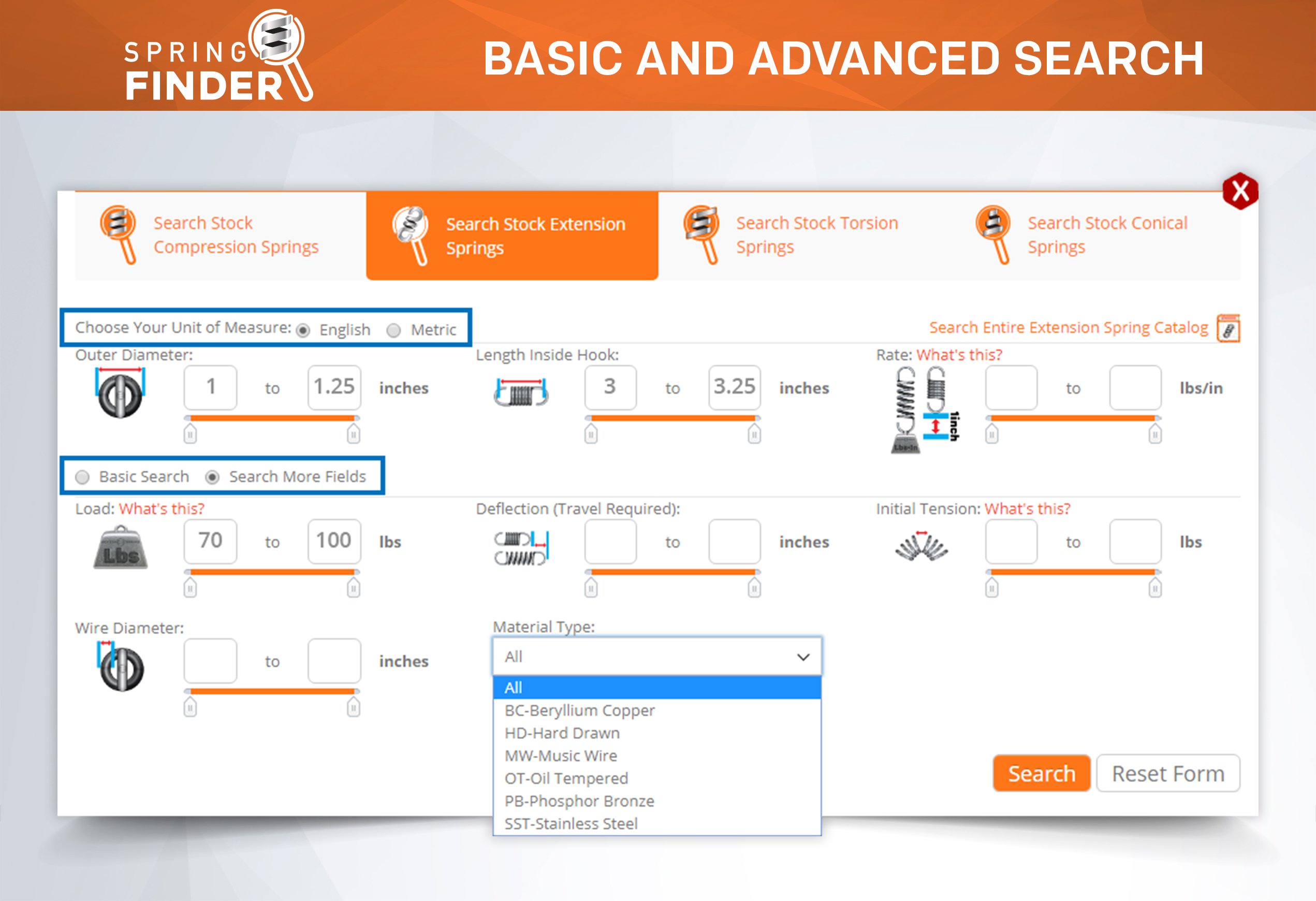

Step 1.) What environment will your spring have to resist?

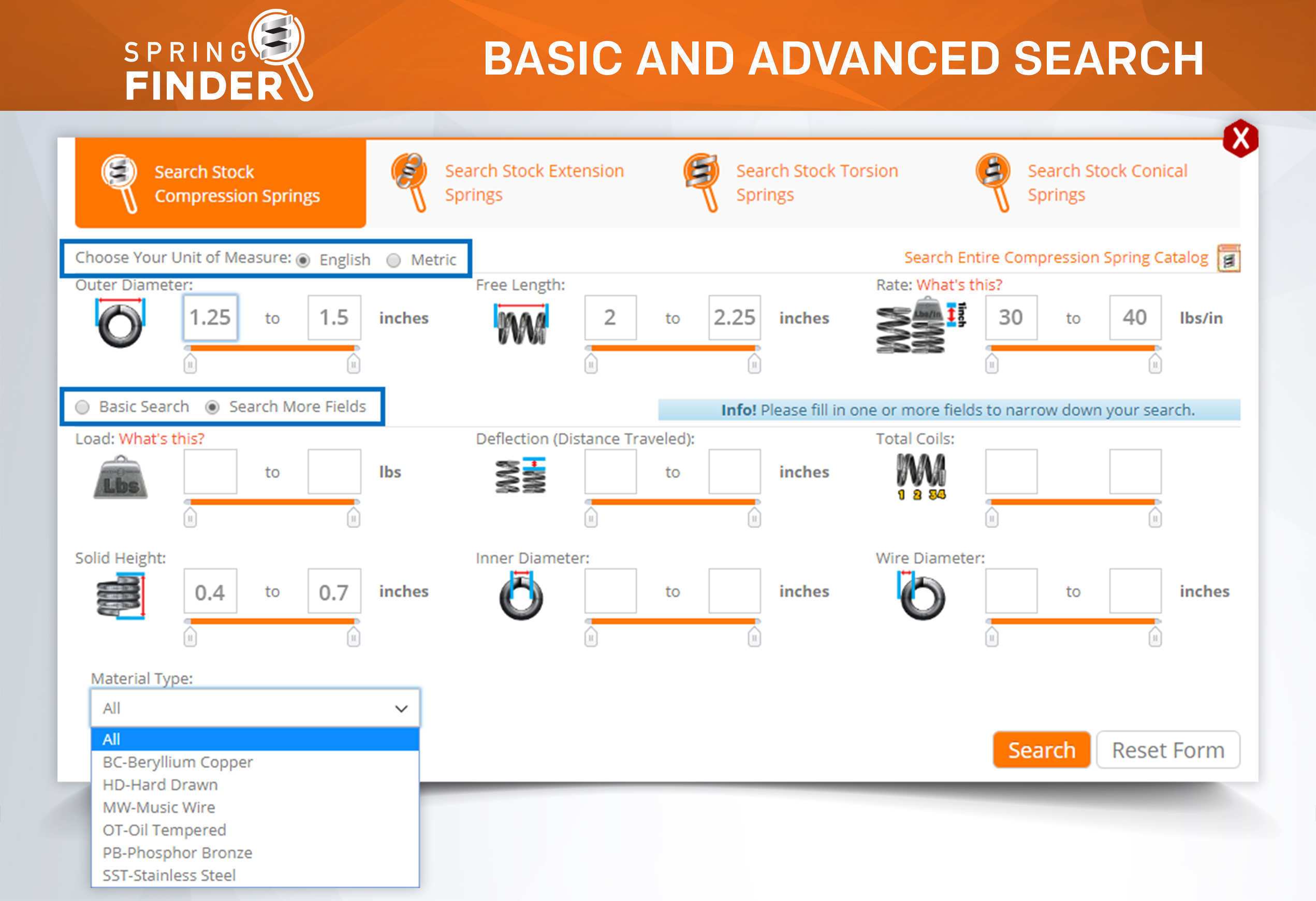

If your spring is required to tolerate high temperatures, moist environments, or needs to be non-magnetic, you must make your design using the correct material or wire type. The material types provided in our helical compression spring design calculator are Music Wire (or spring steel) ASTM A228, Oil Tempered MB A229, Carbon Valve A230, Hard Drawn ASTM A227, Stainless 17-7 A313, Stainless 302 A313, Stainless 316 A316, Chrome Silicon A401, Phosphor Bronze Grade A B159, and Beryllium Copper B197. Different materials have different tensile strengths. Therefore, this step must be done before going into your helical compression spring design's calculations due to the fact that changing the material or wire type later on in the process of your spring calculations can greatly affect your helical compression spring’s force as well as load and travel tolerances. The most common wire type is music wire (also known as spring steel) and it is also the most economic wire type. If there is no need for high temperature resistance or any other special requisites, this is the wire you want to use.

Step 2.) Where will your spring be placed?

If your spring is going over a shaft, inside a hole, or neither, you want to make sure that at the time of installing it in your device, it will fit appropriately and function as required. Usually, when your spring has a small outer diameter and a large free length, it would be a good idea to place it over a shaft or inside a hole. If it is going over a shaft, you will have to be cautious with your spring's inner diameter; if it is being installed inside a hole, you'll have to be cautious with the outer diameter. You must also make sure your helical compression spring won't be too tight around the shaft or hole because after several cycles of compression, the spring may settle a bit. For this reason, you must make sure that you have adequate clearance between the hole or shaft and your helical compression spring. On the other hand, if your spring will not be placed into a hole or over a shaft and has a risk of buckling (bending) when compressed, you might want to take double closed and ground ends into consideration or perhaps a conical, convex, or concave compression spring to provide better footing. The helical compression spring design calculator will provide you with helpful warnings and tips in case that your helical compression spring has a risk of buckling once compressed.

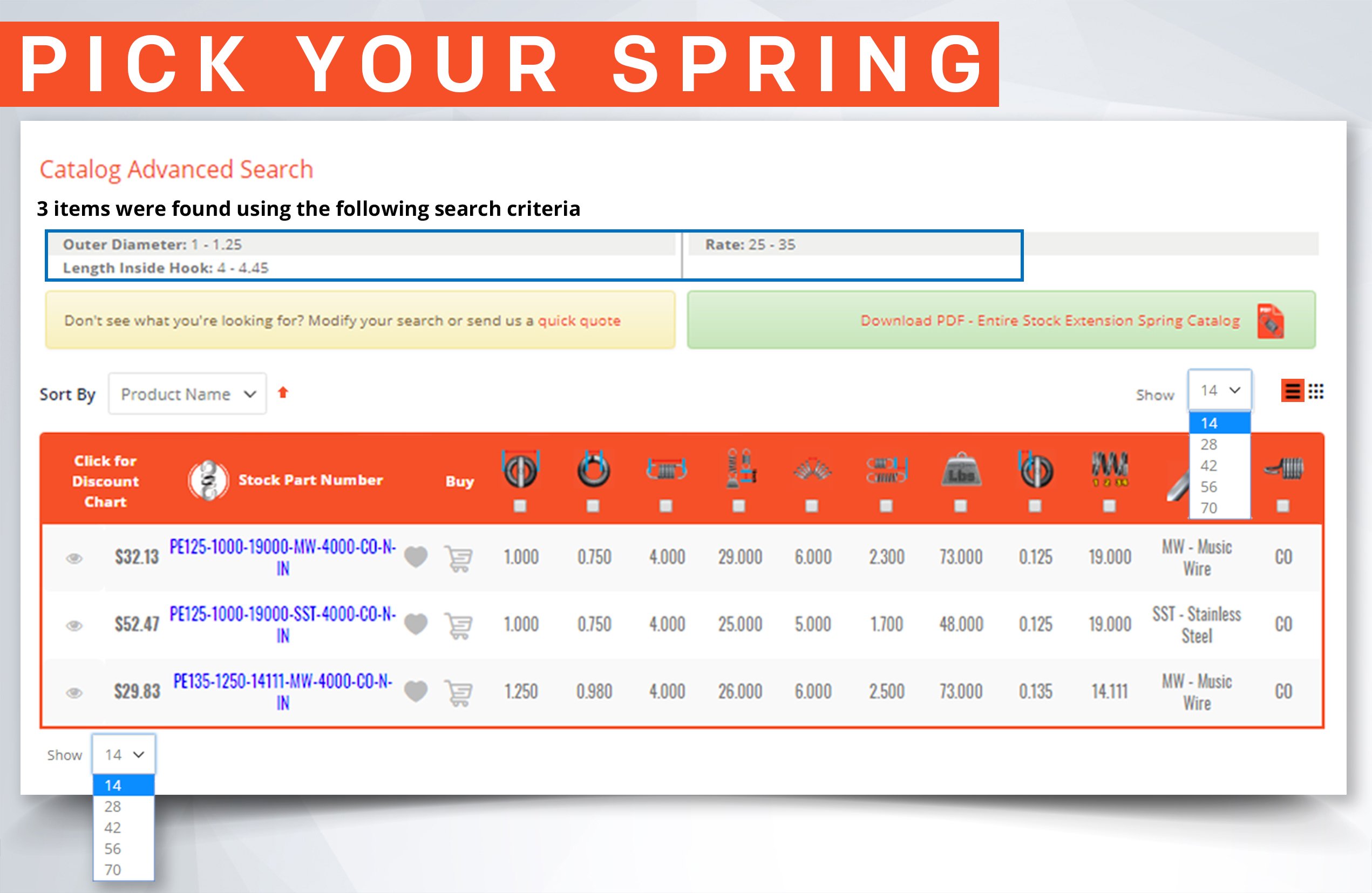

Step 3.) How much load will be applied on your spring and how much is the distance traveled once this load is applied?

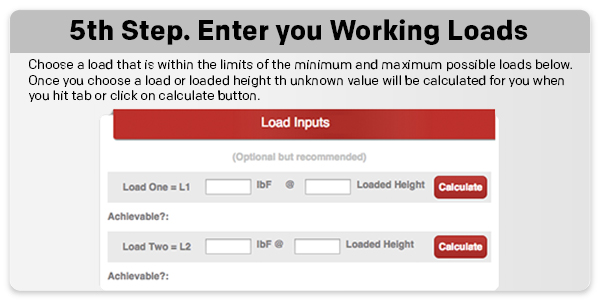

Knowing these values will give you the rate of force your spring will need to expel in order to meet your application's requirements. Load is the weight that will be applied to your spring to make it compress. Distance traveled is the distance your spring travels from your helical compression spring's free length to its loaded height. Loaded height is the height of your helical compression spring once it is compressed. Spring creator includes a section where you may calculate the loaded height by only inputting your required load. You may also calculate the amount of load you need by inputing your desired loaded height.