Static Load Vs. Dynamic Load in Springs

Springs are made to react based on the load applied. Compression springs compress when a load is placed on them. Extension springs expand when a load pulls on them and torsion springs torque when a load is applied to them. Normally, we go through explaining the spring itself. However, today we want to focus on explaining the actual load and the difference between a dynamic load and static load, along with the role that the spring rate plays, as these are important factors when designing the spring you want.

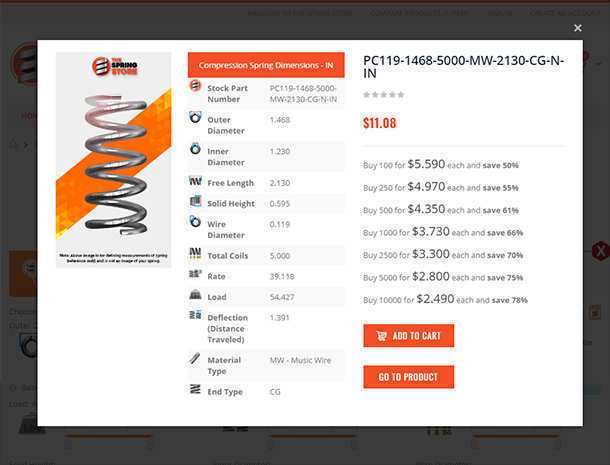

A spring’s working load determines a specific amount of force at a desired loaded height or distance traveled. The load is what causes the deflection to take place and how far your spring compresses, extends or torques are based on the rate. The load can be either dynamic or static, and in some cases, springs may experience one or the other, or both!

A static load is a fixed load or a force applied gradually. For example, a spring that is simply holding something would be considered a static load. However, once the spring starts moving, it would be considered a dynamic load for it fluctuates and has cyclic repetitions.

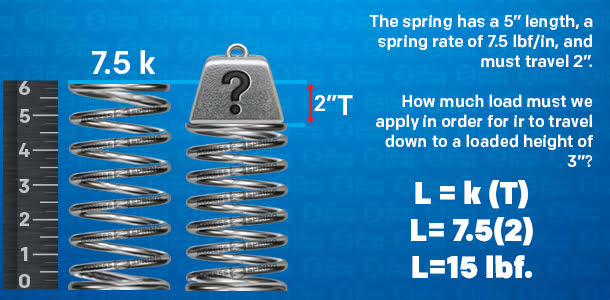

Spring rate determines the amount of force required for a spring to travel one inch of distance from its free length to a loaded height. It can be used to calculate the amount of static load required for spring to travel a certain amount of distance, or the amount of distance a spring will travel under this static load. For example, if you have a compression spring with a 5-inch free length that you need to compress down to a 3-inch loaded height under a constant load, the distance traveled would be 2 inches. If that spring has a spring rate of 7.5 pounds per inch, it would take 15 pounds for it to travel 2 inches. On the other hand, if you know you will be putting a load of 50 pounds on a spring with a rate of 40 pounds per inch, the distance traveled would only be 1.25 inches.

A Dynamic load is a changing load, pressure or force that can be applied varyingly. When talking about springs, we can use the following example: If a cart had wheels with a suspension system that contained springs in them, those springs would be under a static load when the cart is not in motion. However, once the cart is in movement, the springs would undergo a dynamic load as the force and travel will vary through different pavement and road conditions. In springs, the dynamic load is not something that can be specifically calculated but can be averaged out. You would need to consider this as another factor and consider the range of the dynamic load.

Understanding loads, rate and spring design is not always easy, but we try to explain and simplify as best as we can. However, if you need further assistance do not hesitate to contact us at: [email protected]

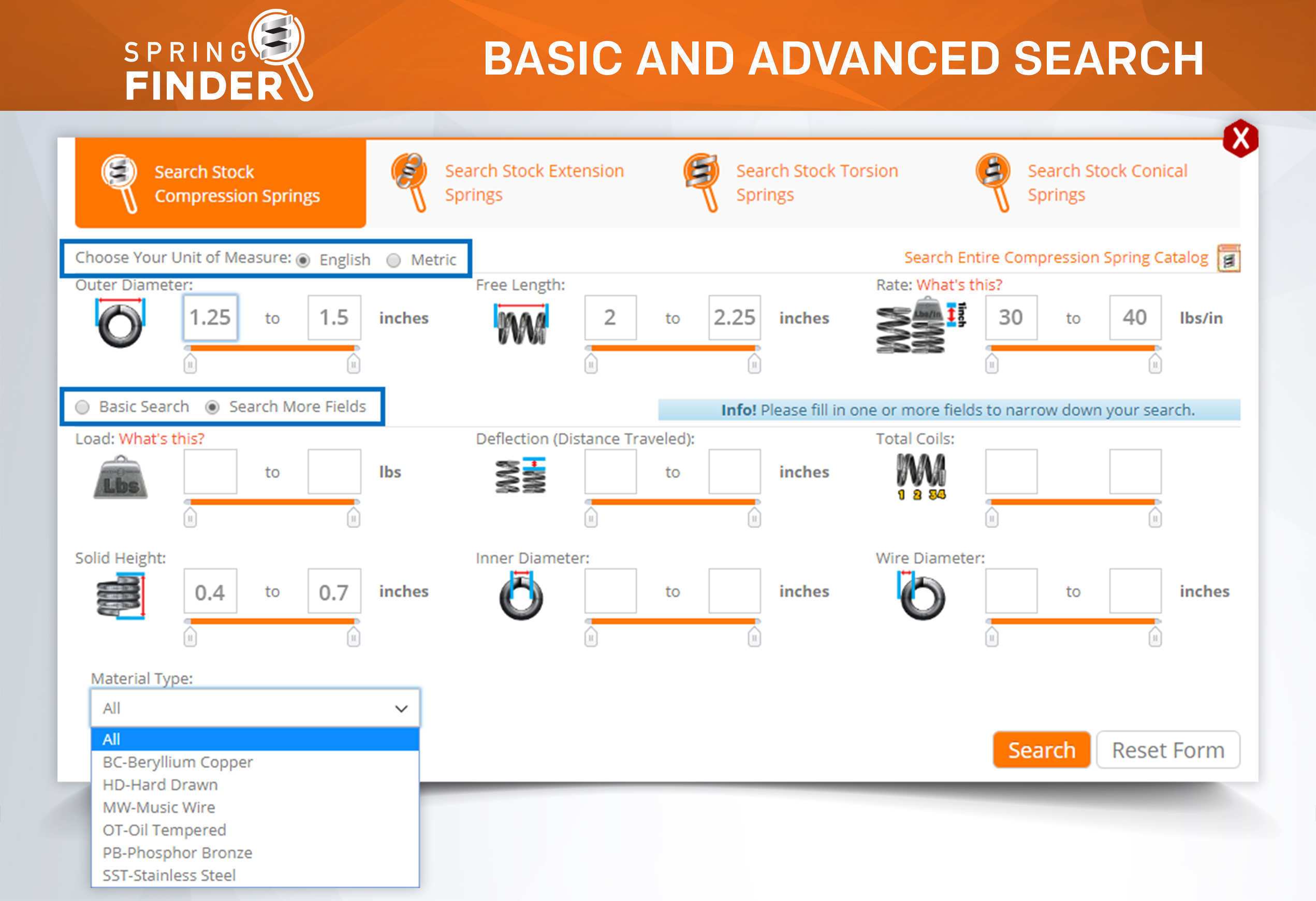

We make purchasing stock and custom springs easy and provide spring rate and other spring analysis information immediately in our spring creator calculator. CLICK HERE

Should you need to order a custom spring you can get an instant quote and purchase online. Get a Instant Spring Quote.

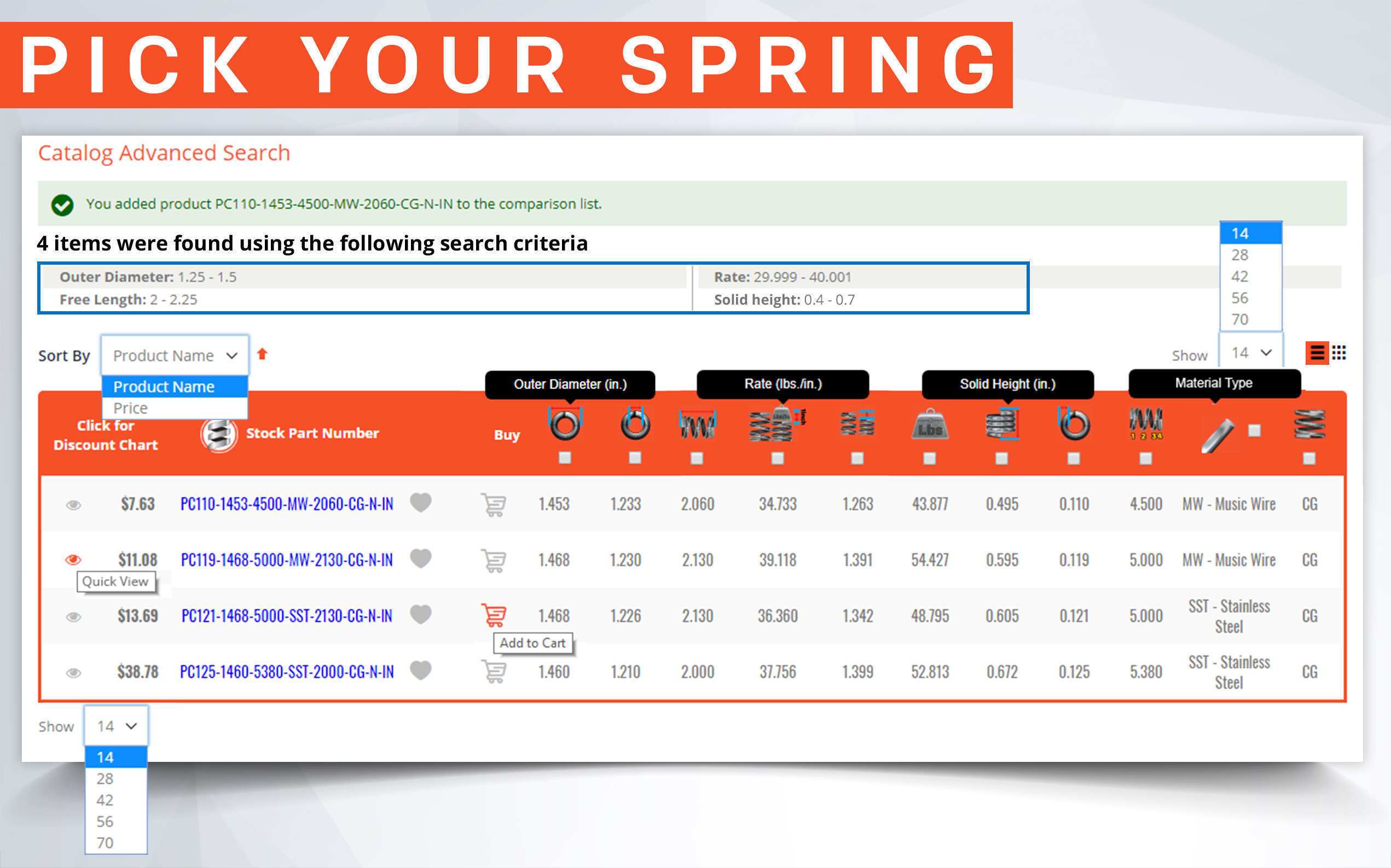

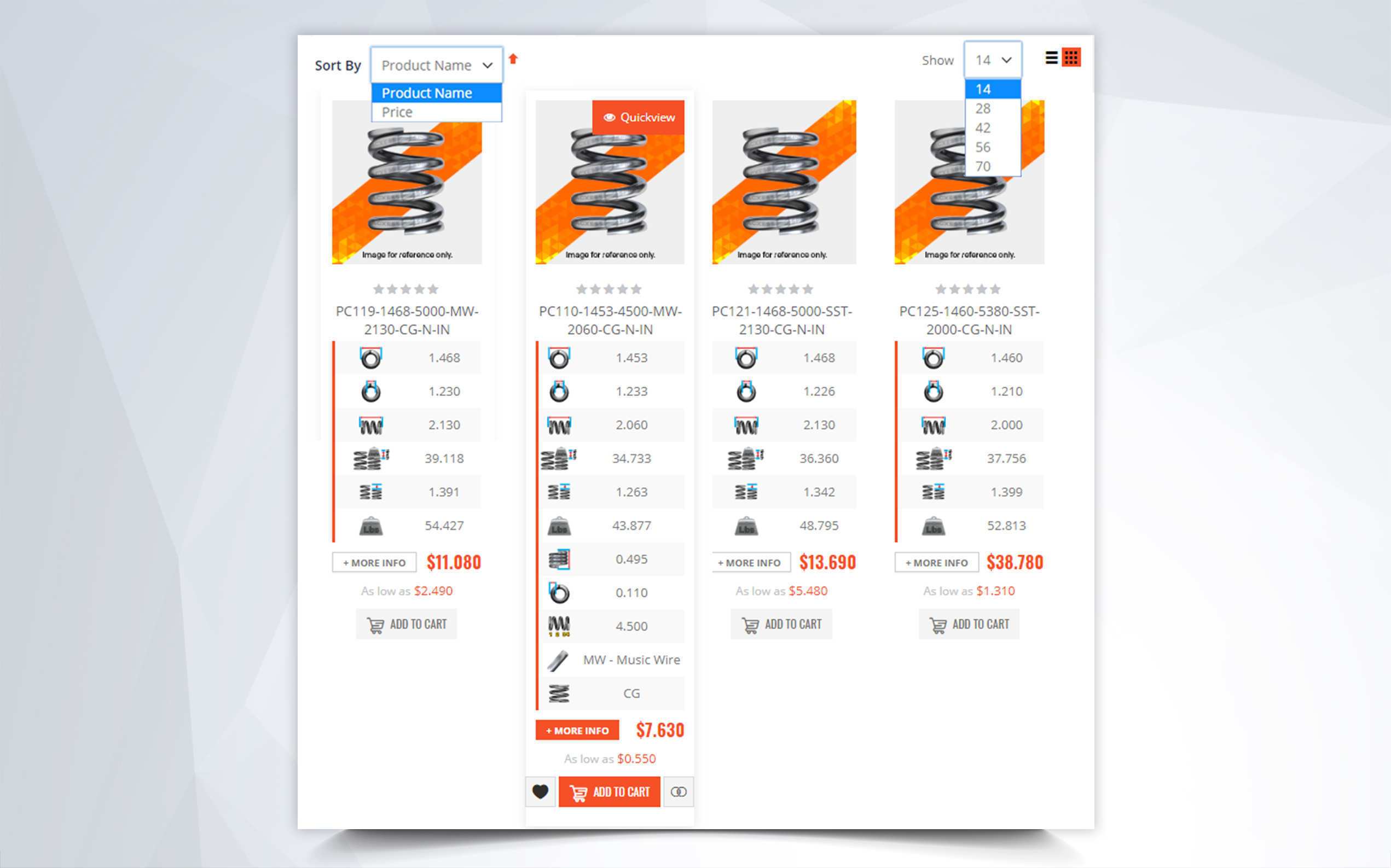

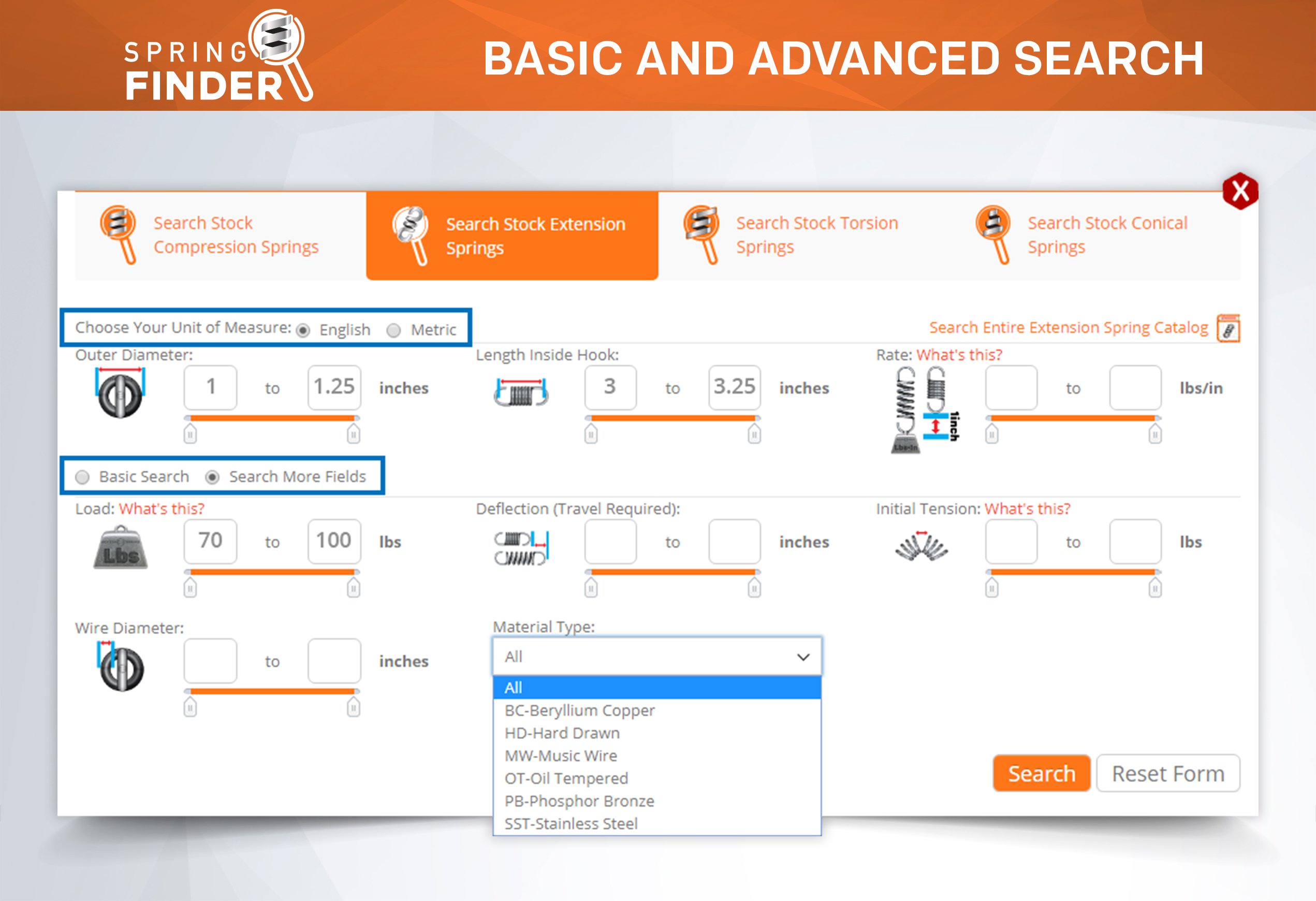

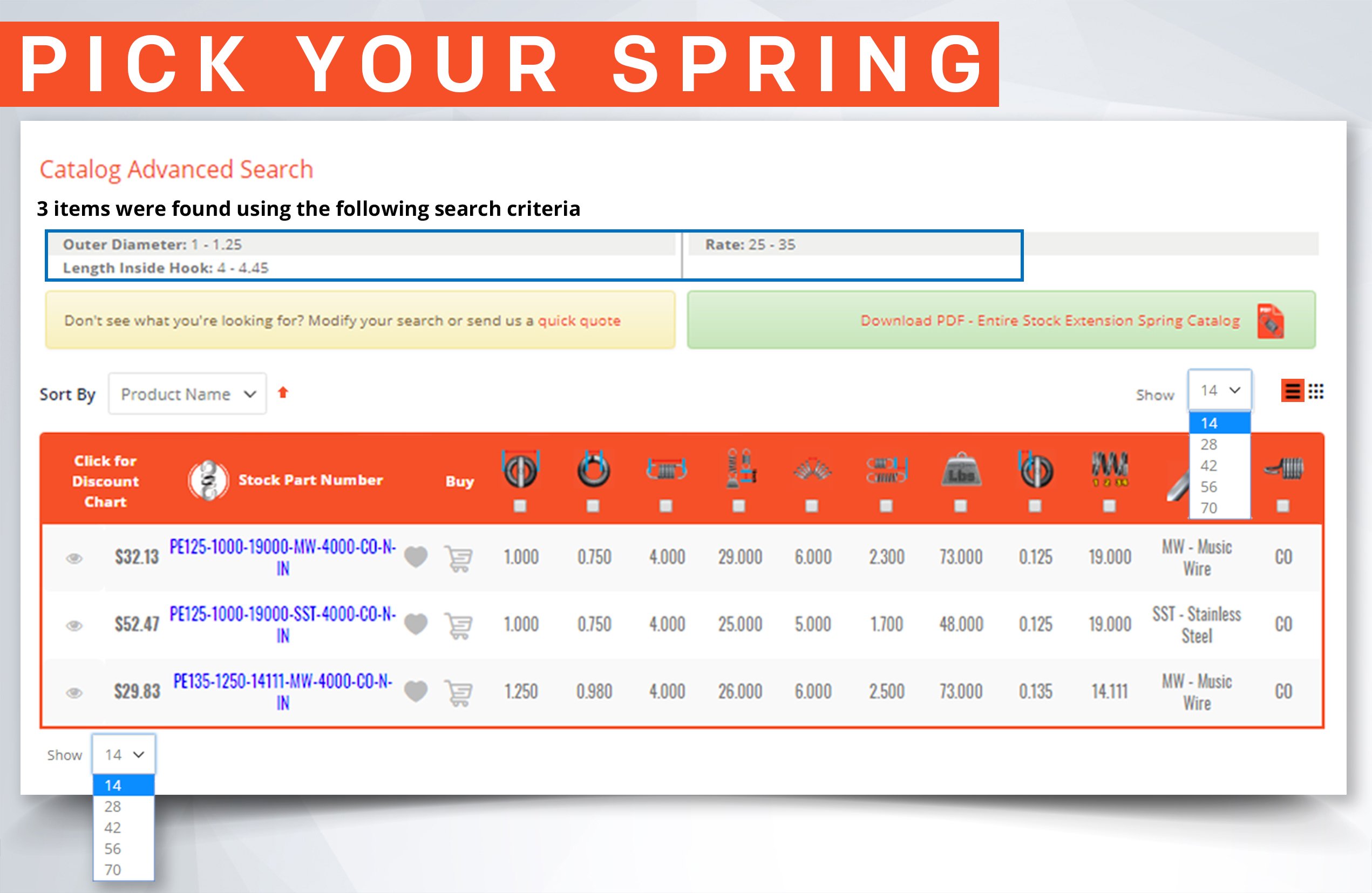

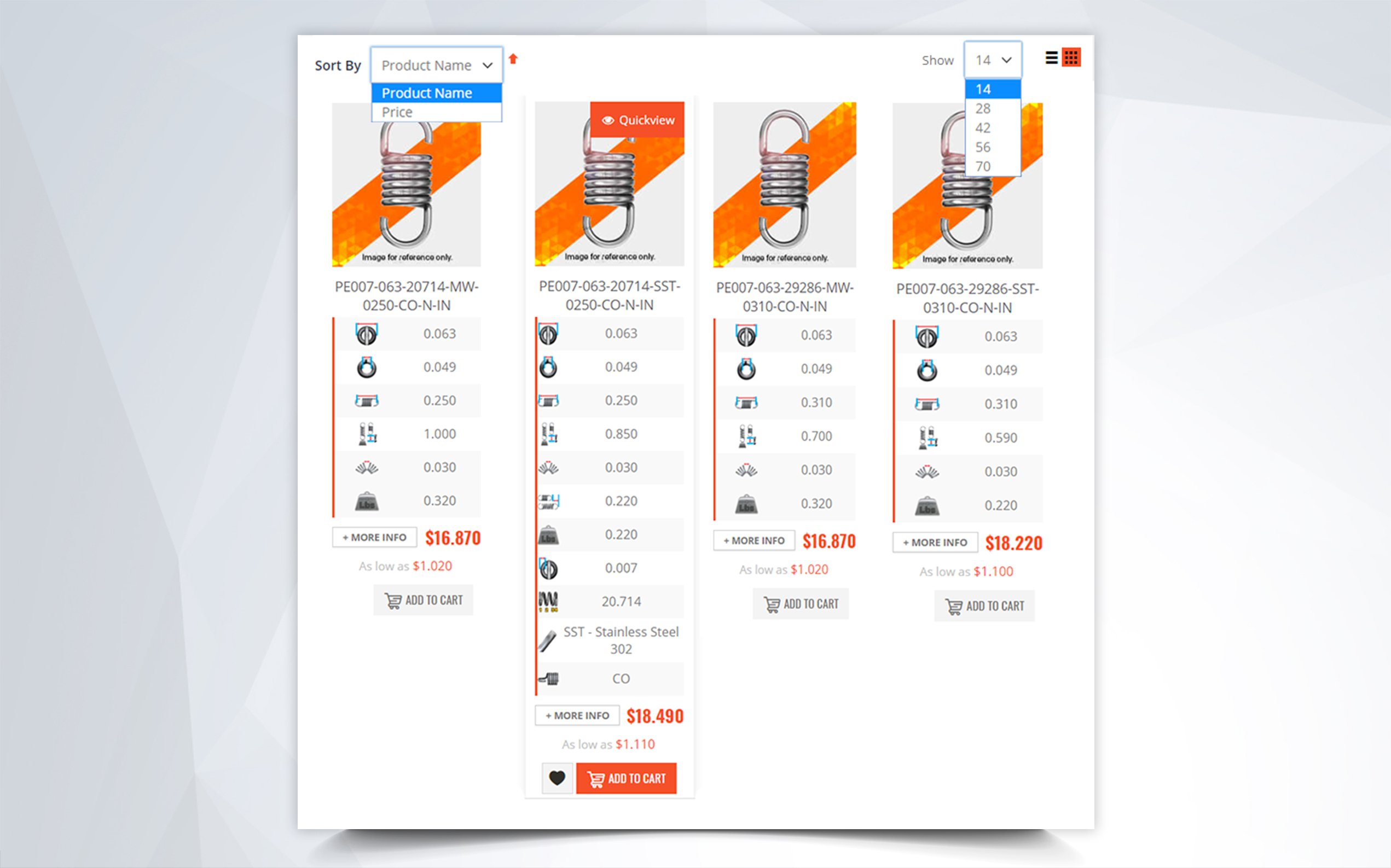

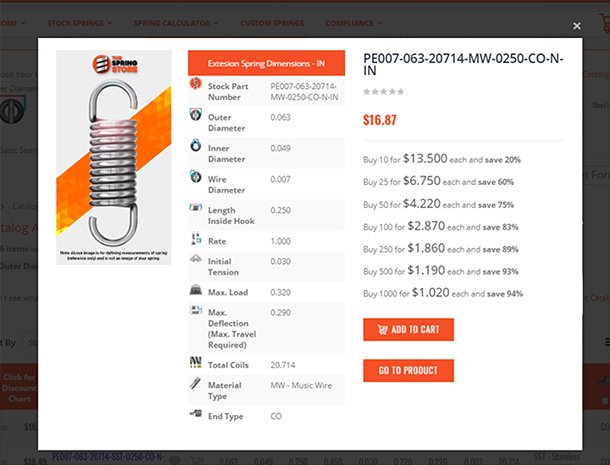

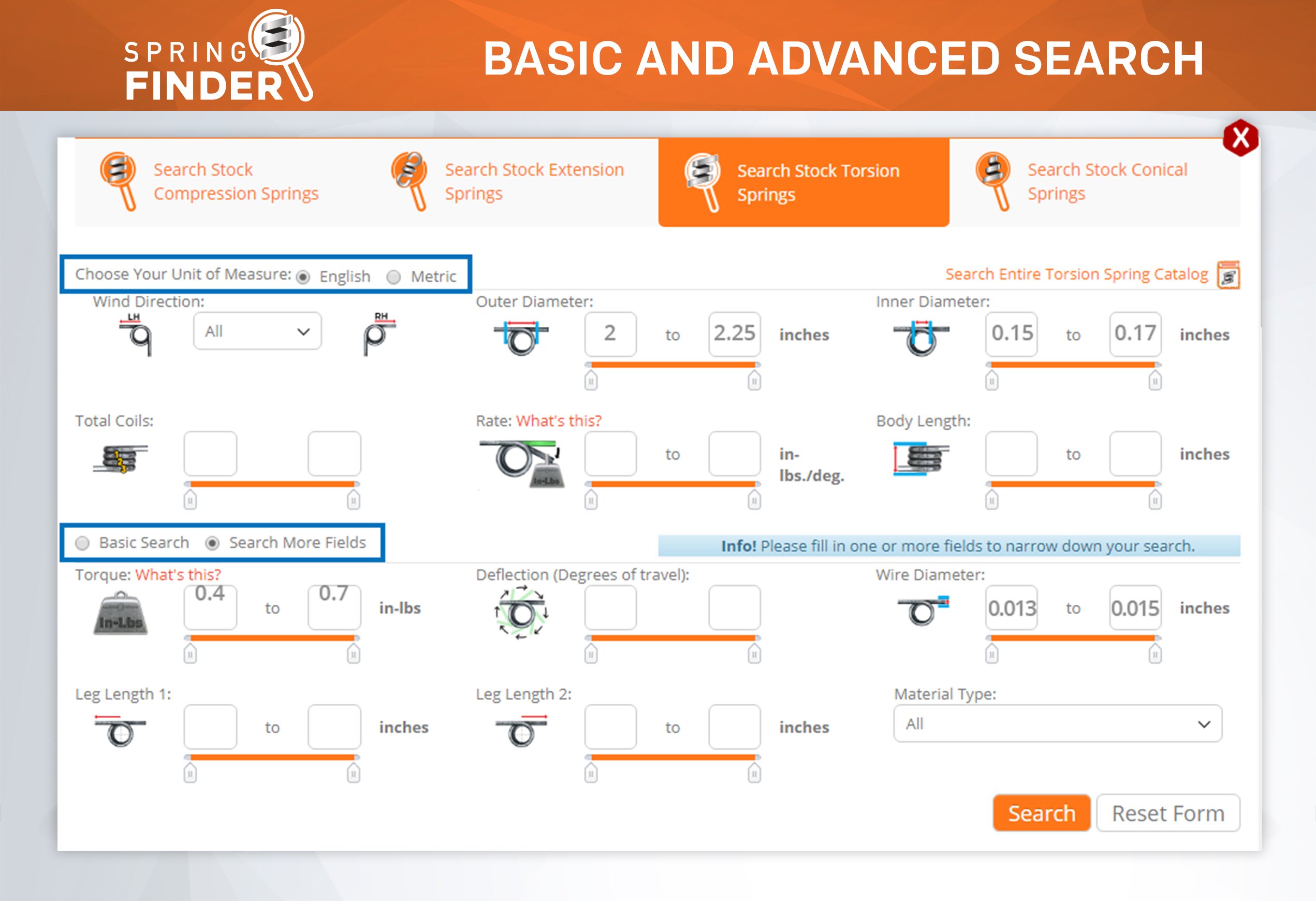

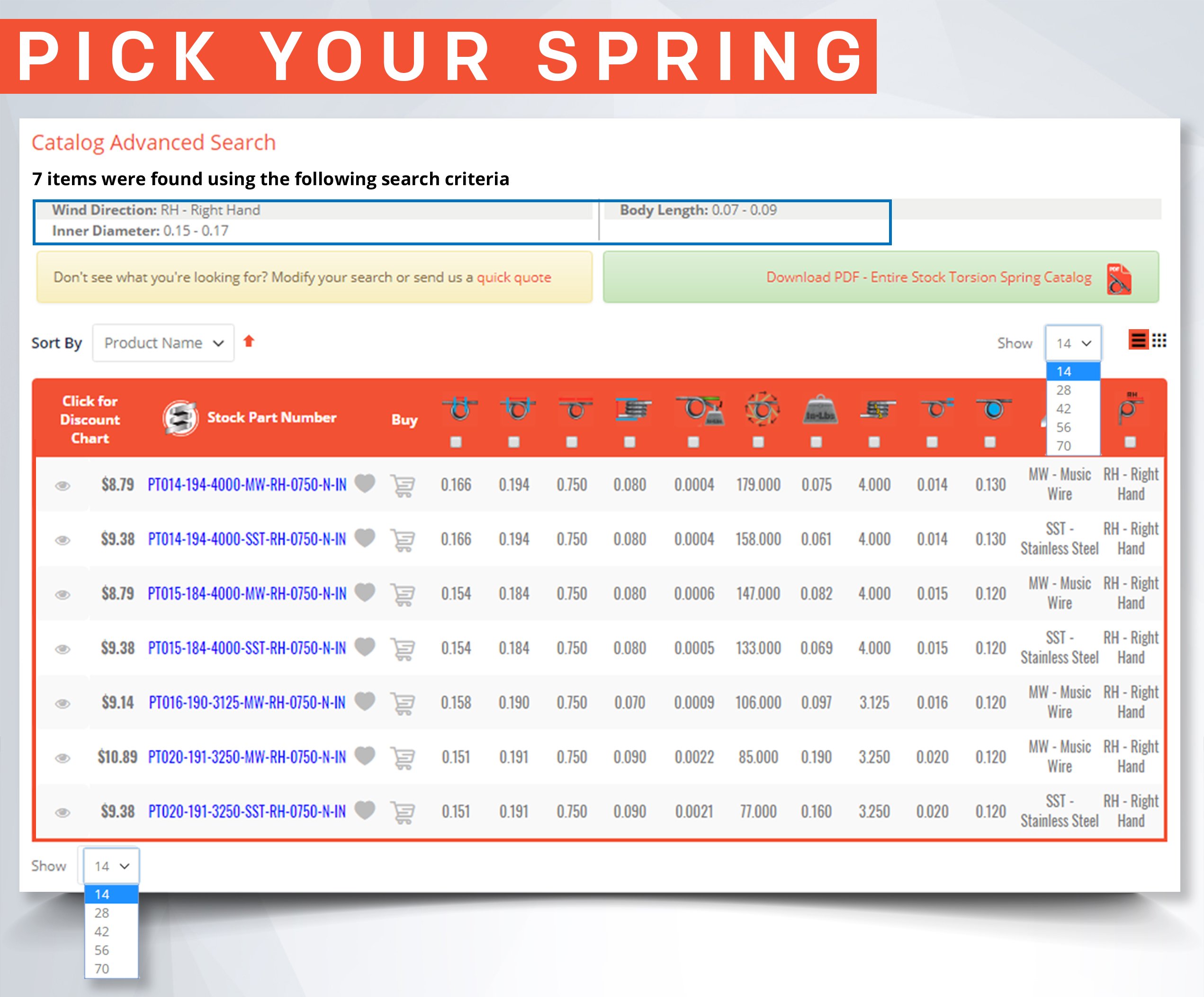

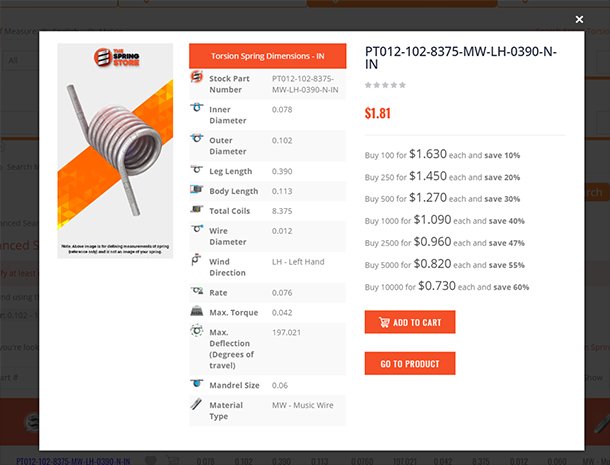

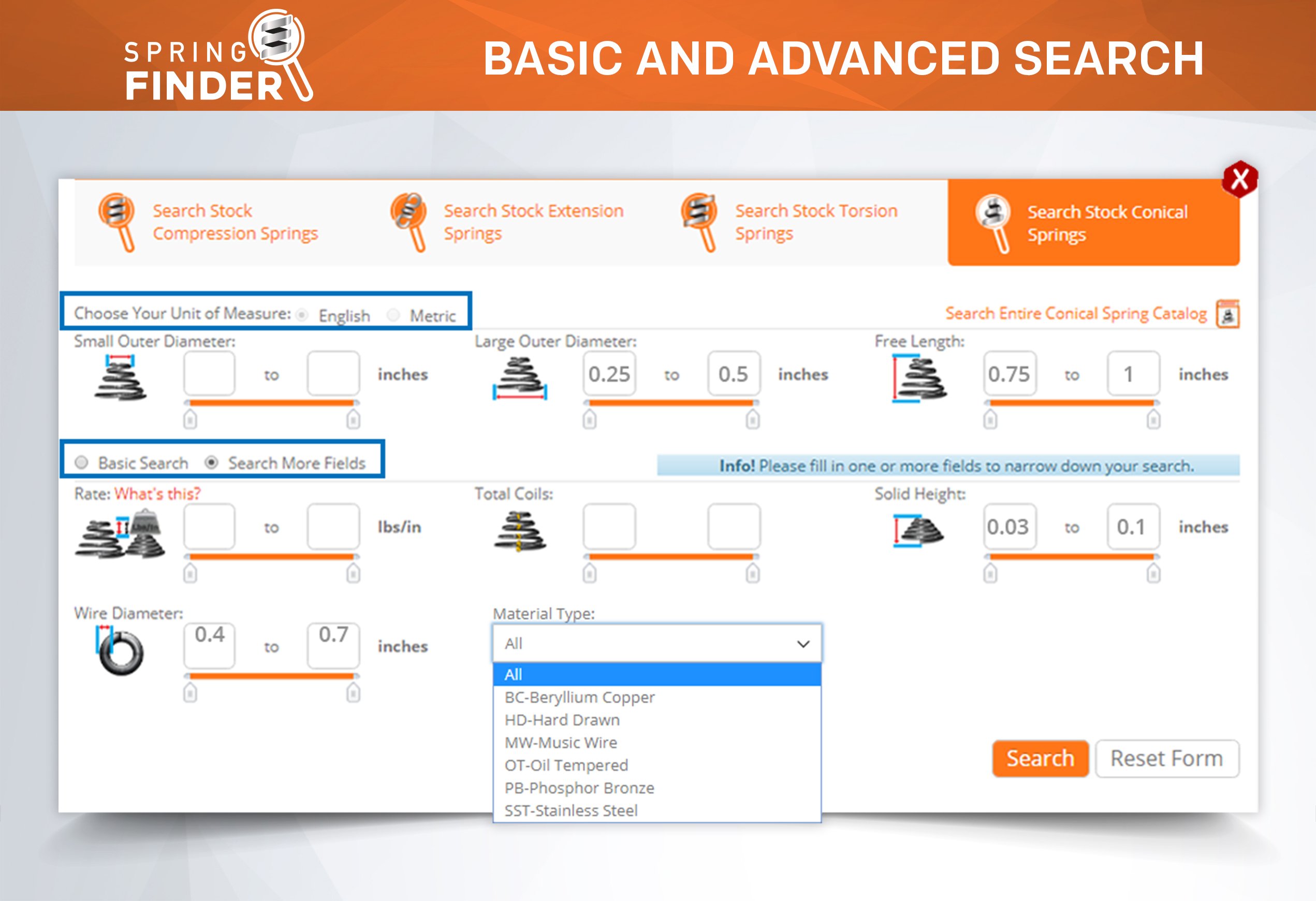

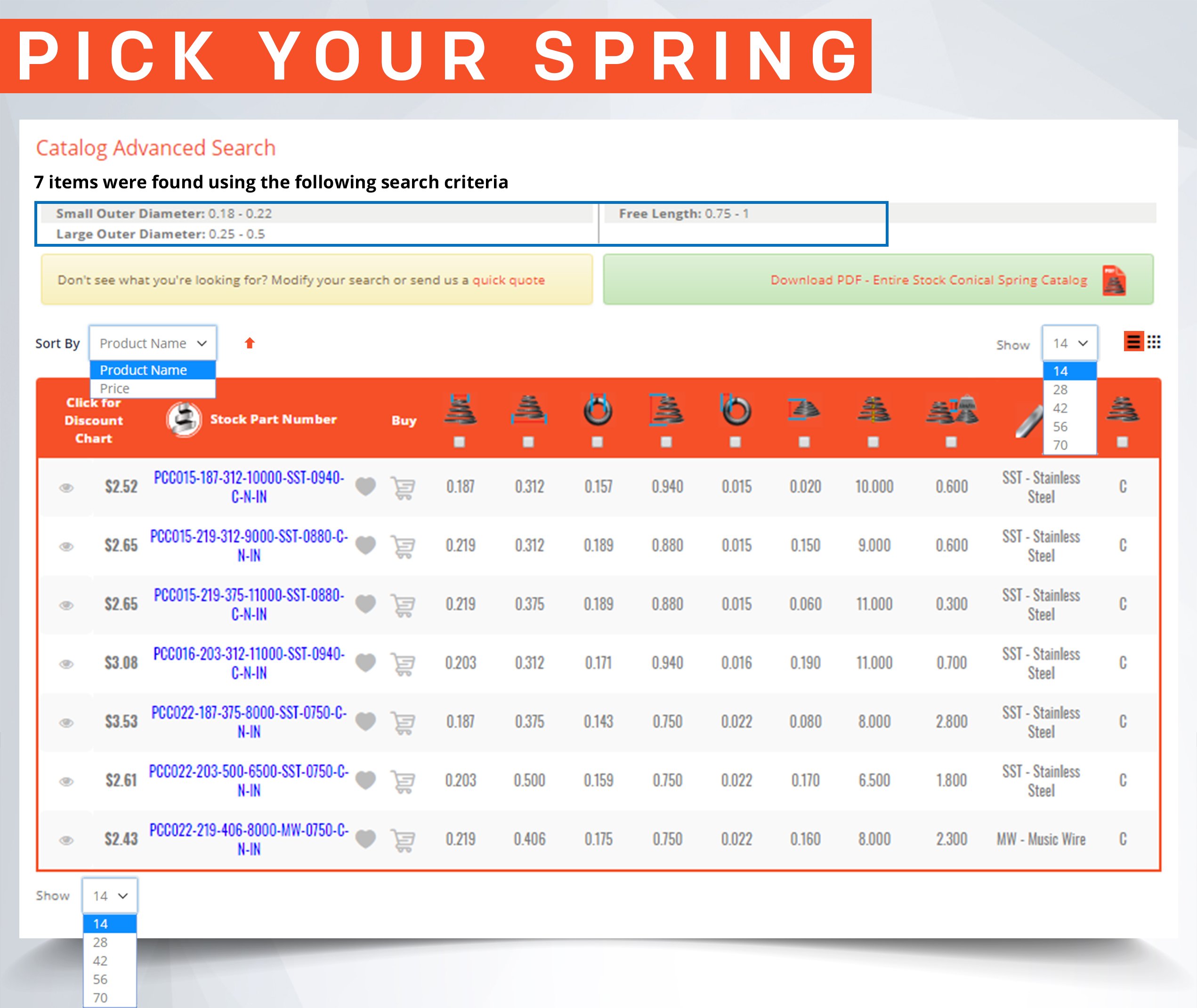

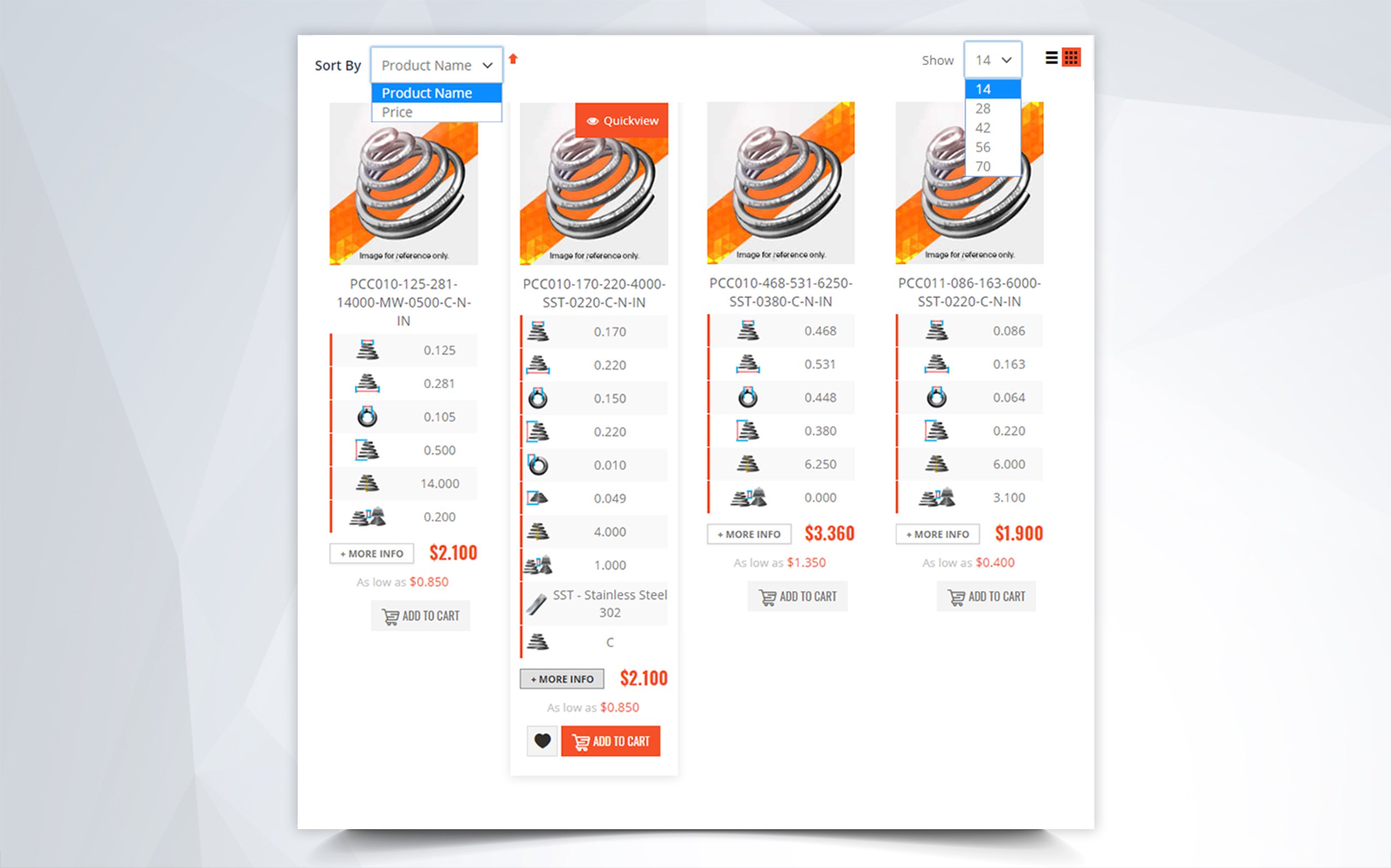

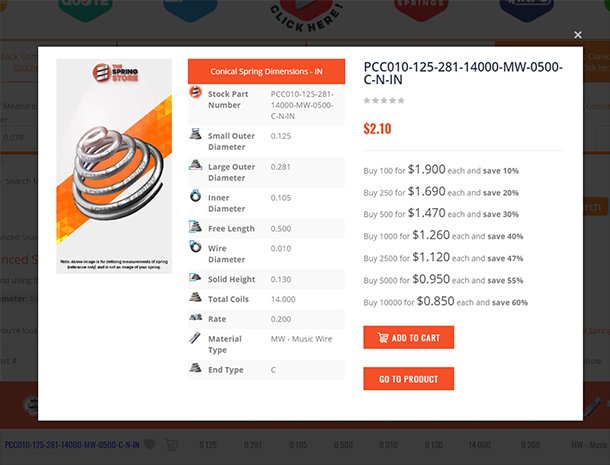

Looking for a stock spring? Use our spring finder. CLICK HERE