Tapered Springs Explained

Tapered springs are also known as conical springs. This name comes from its shape since the term tapered means to reduce in thickness toward one end. As you can see a tapered / conical spring is just that, a spring with coils that are reduced in shape as they coil and form a cone structure. They are used to provide balance and reduce the solid height by the coils telescoping into each other.

Telescope Effect

Thanks to the tapered shape some of these springs can have the diameters of each coil perfectly adjusted to create what is called a telescope effect. Those tapered springs with this telescope effect function can collapse fully into a one wire diameter solid height, when compressed.

This allows the user to compress the spring all the way down so that all the coils of the spring collapse inside themselves down to one wire diameter (the thickness of one wire) which provides more travel or deflection. This is ideal when the creator of a product requires the spring to have more deflection (the distance the spring has deflected or compressed) but there is not enough space for a longer spring.

Tapered Springs Offer Greater Stability

Tapered springs also offer an advantage over basic compression springs when it comes to stability. The large outer diameter (The measurement of the Outer diameter of the outside coils of the spring’s body) is usually on the bottom, this creates a stable base which reduces buckling (bending of a spring, see image) when being compressed.

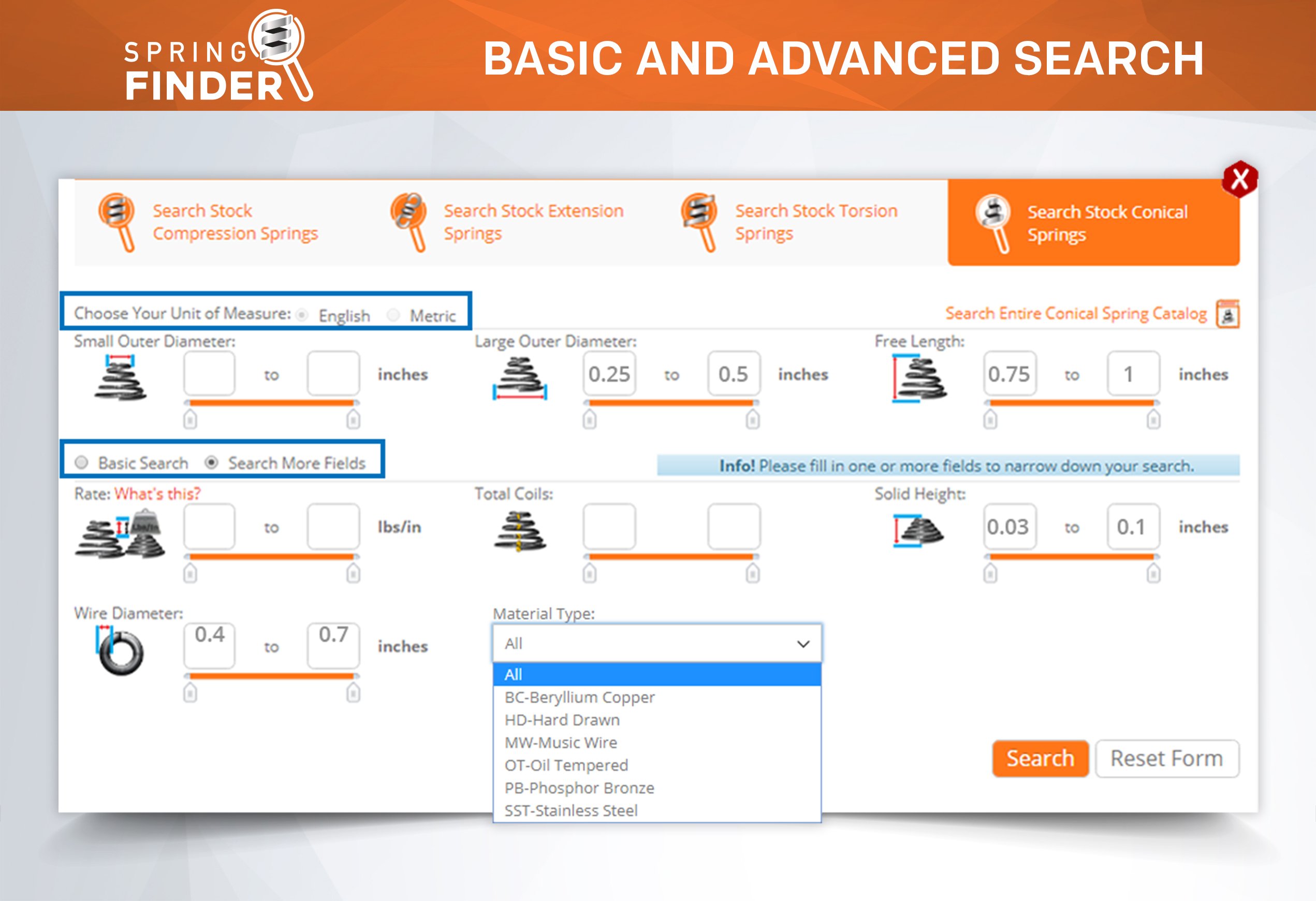

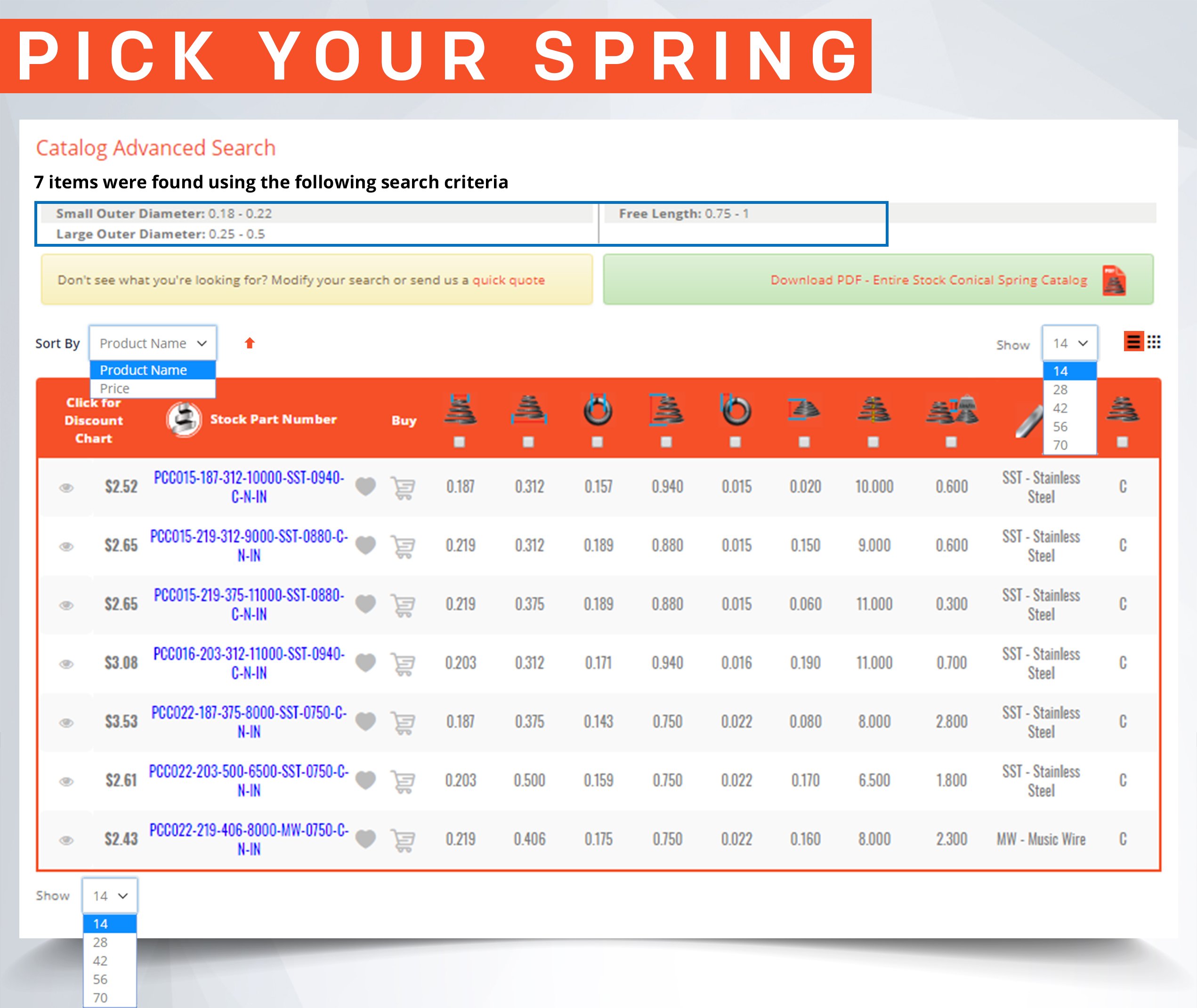

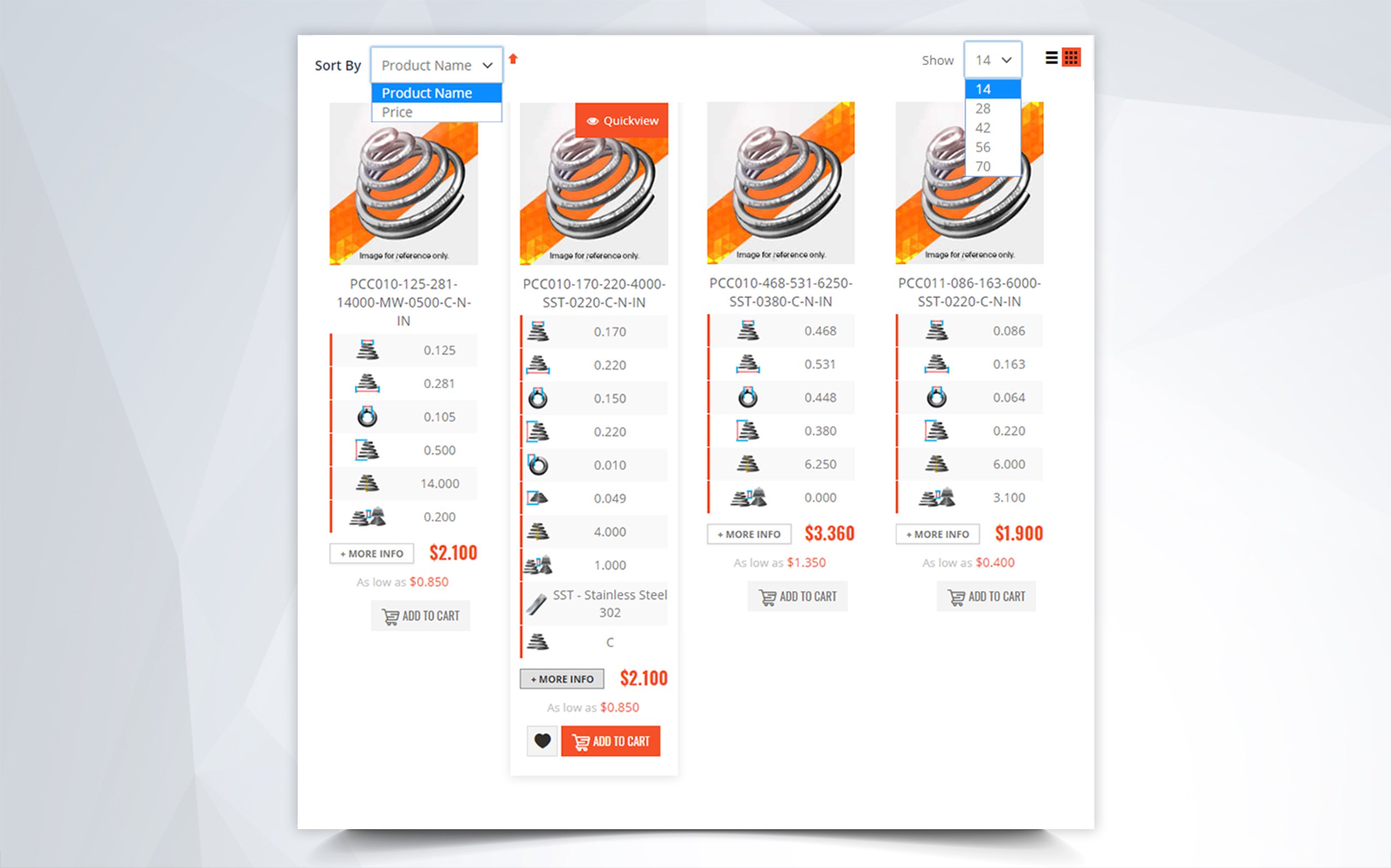

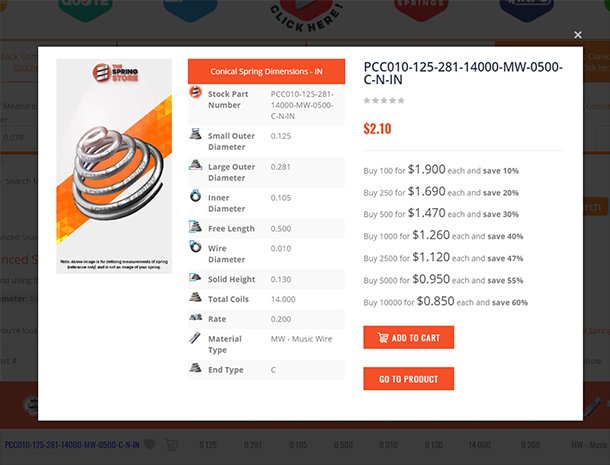

Conical Spring Dimensions

There is also some different terminology and dimensions that apply to tapered springs. The main difference is in regards to the coil’s diameter. In a normal compression spring all the wire diameters are the same thickness but when it comes to conical springs you don’t have just one OD (Outer Diameter) and ID (Inner Diameter) , rather there are multiple and these need to be distinguished by the largest and the smallest. Therefore, when measuring dimensions of a tapered spring we take into consideration the larger outer diameter, the small outer diameter and the inner diameter is taken from the width of the inside of the smallest coil. You can learn more about this and see a breakdown in the following page: Tapered Spring Terminology and Dimensions