Design a Helical Compression Spring for a Static Load

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

Definition: The process of designing a helical compression spring that will be able to hold a continuous (static) load.

If you want to learn the step by step process of designing a helical compression spring for a static load, you have found the best spring calculation software online to do so. Our spring calculator, which has been provided below, is an advanced spring design tool which helps you to calculate your helical compression spring design data. Follow the step by step process in our helical compression springs load calculator to generate the ideal compression spring for your application or mechanism.

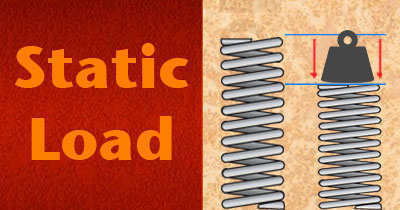

A static load is a force which remains stationary while a

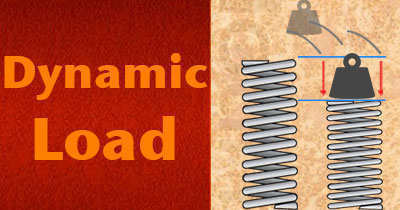

dynamic load is a force that is in motion, causing inertia.

In step one and step two of our calculator is when you enter your spring’s physical dimensions. Step one asks you to pick a helical compression spring end type. The end types provided are closed and squared ends, closed and ground ends, double closed ends, and open ends. In step two you are required to enter your compression spring measurements which are wire diameter, outer diameter, free length, active coils, and material type.

The following steps are the results of your helical compression spring design.This is where you will see if your helical compression spring will be able to hold your static load. You are provided with spring rate which determines the strength of your compression spring by telling you the amount of static load you will need in order for it to travel one inch (one millimeter in metric units). The next values are maximum load considering solid height and true maximum load.

Based on your spring's dimensions, you will be able to determine the elastic limit of your spring. If the spring has tight dimensions which cause it to have a lot of stress, you might not always be able to travel down to solid height. On the other hand, if your spring has lose dimensions it might be able to travel down to solid height and you may even have the possibility to extend your free length and get more static load or travel out of the spring. This is where the true maximum load comes in. The true maximum load is the amount of load your spring design is able to achieve if you were to extend the free length. The maximum load considering solid height id the load you are able to get out of your spring if you leave the design as it is.

To get the most travel or static load out of your spring you may subtract the maximum load considering solid height from the true maximum load and add the result to your helical compression spring’s free length. Then both values should appear the same on your calculation’s results.