Solid Height in Compression Springs

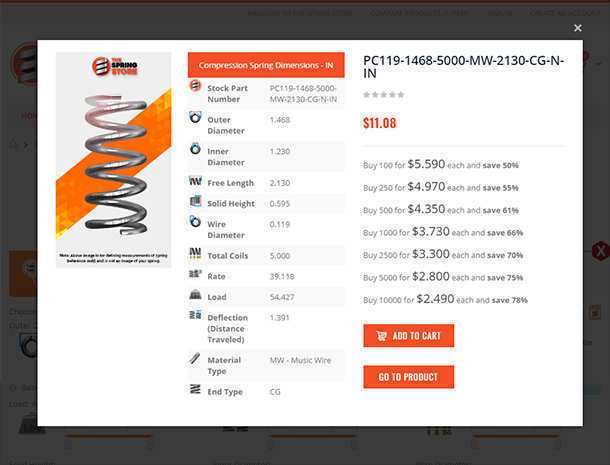

Solid height is the term that refers to the length/height of the spring once it has been compressed to the point where all of the spring’s coils are touching. Solid height is an important factor when it comes to spring design and function. It also plays an important role when it comes to understanding max deflection and elastic limit.

In order to calculate solid height you need to verify whether the spring has closed and square ends or close and ground ends. It is a simple two step process of figuring out the total wire and multiplying this by the wire diameter. You just need to figure out the total wires and multiply this by the wire diameter. Take a look at the formulas below.

Calculating Solid Height (Closed And Square Ends)

The formula for calculating solid height on closed and square ends is:

Total Wires = Total Coils + 1 Solid Height = Total Wire * Wire Diameter

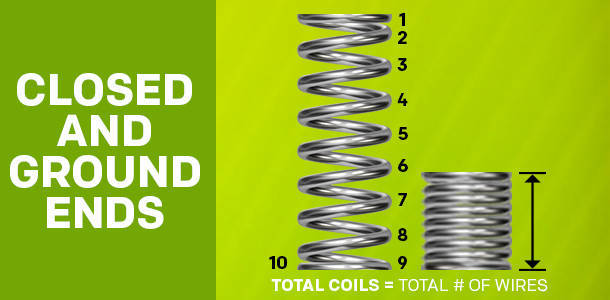

Calculating Solid Height (Closed And Ground Ends)

The formula for calculating solid height on closed and ground ends is:

Total Wires = Total Coils Solid Height = Total Wire * Wire Diameter

Solid Height and Max Deflection

Although, in theory, a compression spring should be able to compress down to solid height, it doesn’t mean it will. Depending on the physical dimensions of the spring, a compression spring may be able to fully compress safely. In other cases, where the spring is too stiff, it may be under too much stress to allow it to compress all the way to solid height. To determine the height a spring can safely compress to, and if that height is the solid height, you can use the following formula:

Free Length - Max Deflection = Min. Loaded Height

Subtract the max deflection from the free length and the result is the height your spring can safely reach (AKA Min. Loaded Height). In many cases, this value may be equal to the solid height, which means your spring will safely deflect down to solid height in terms of elastic limit.

Terminology

Max Deflection - also known as Elastic Limit; it is the measure of resiliency that determines how much a spring can be compressed without being permanently distorted or damaged.

Free Length- the length of the spring in its free state without load applied to it.

Solid height and spacing

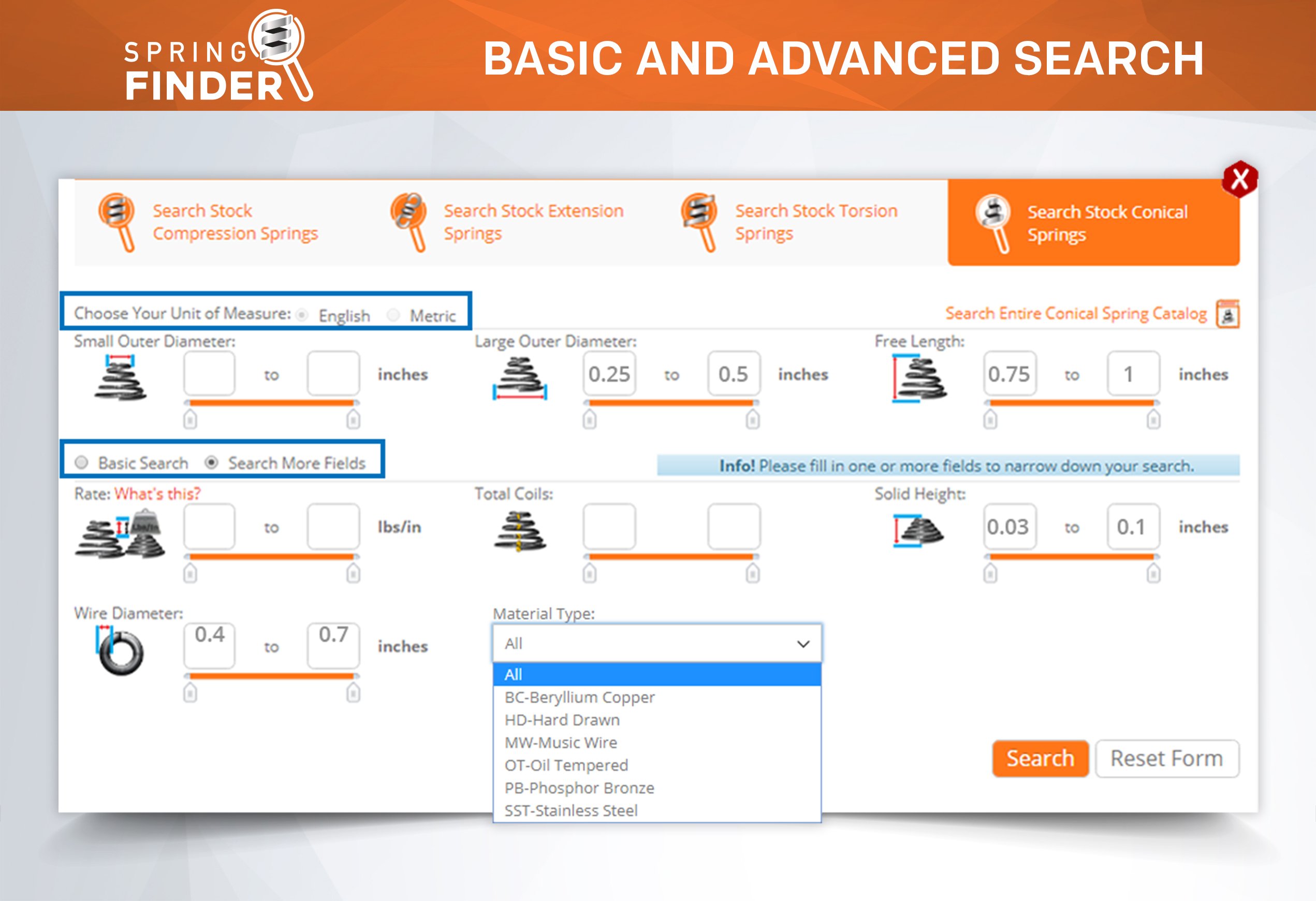

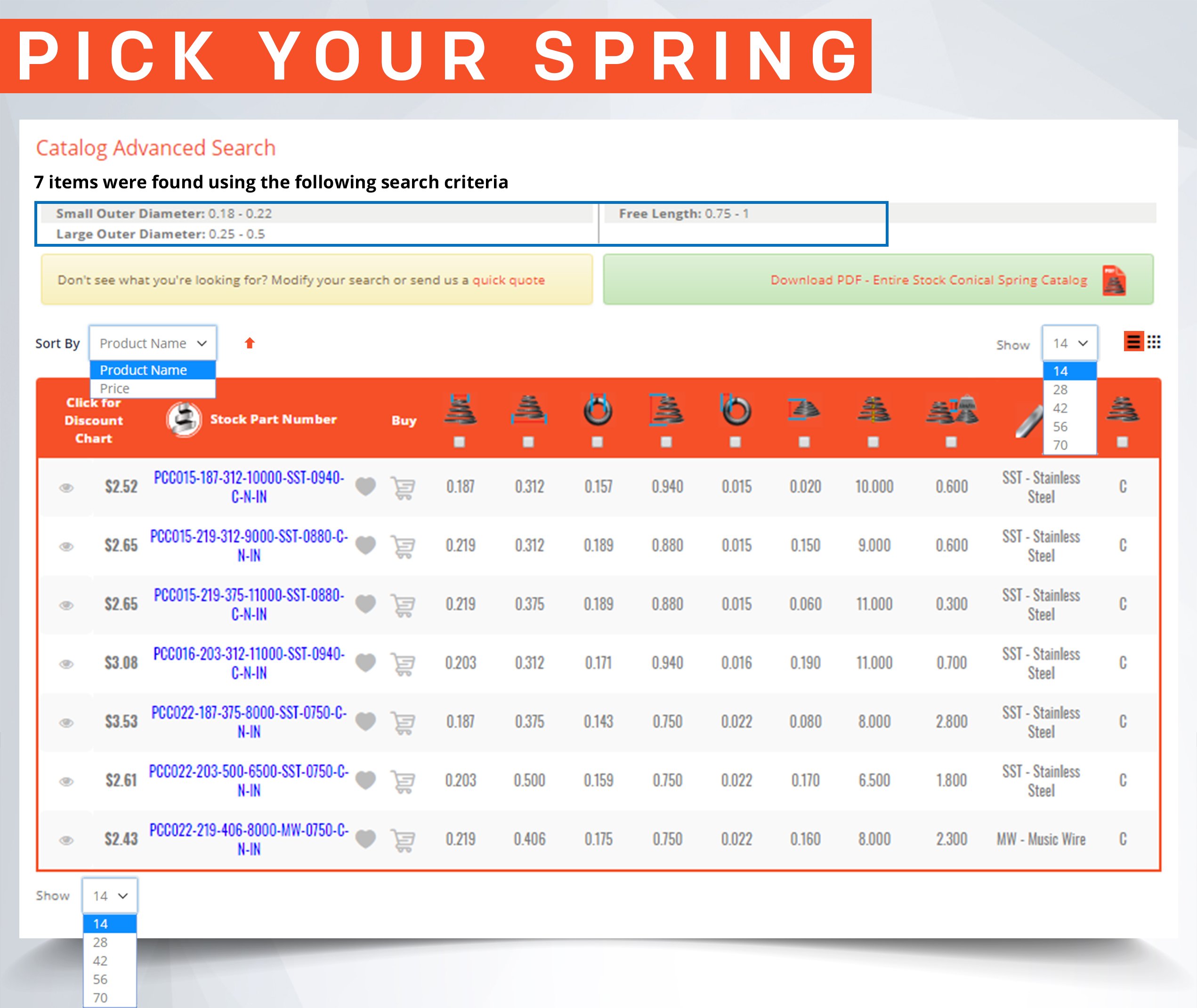

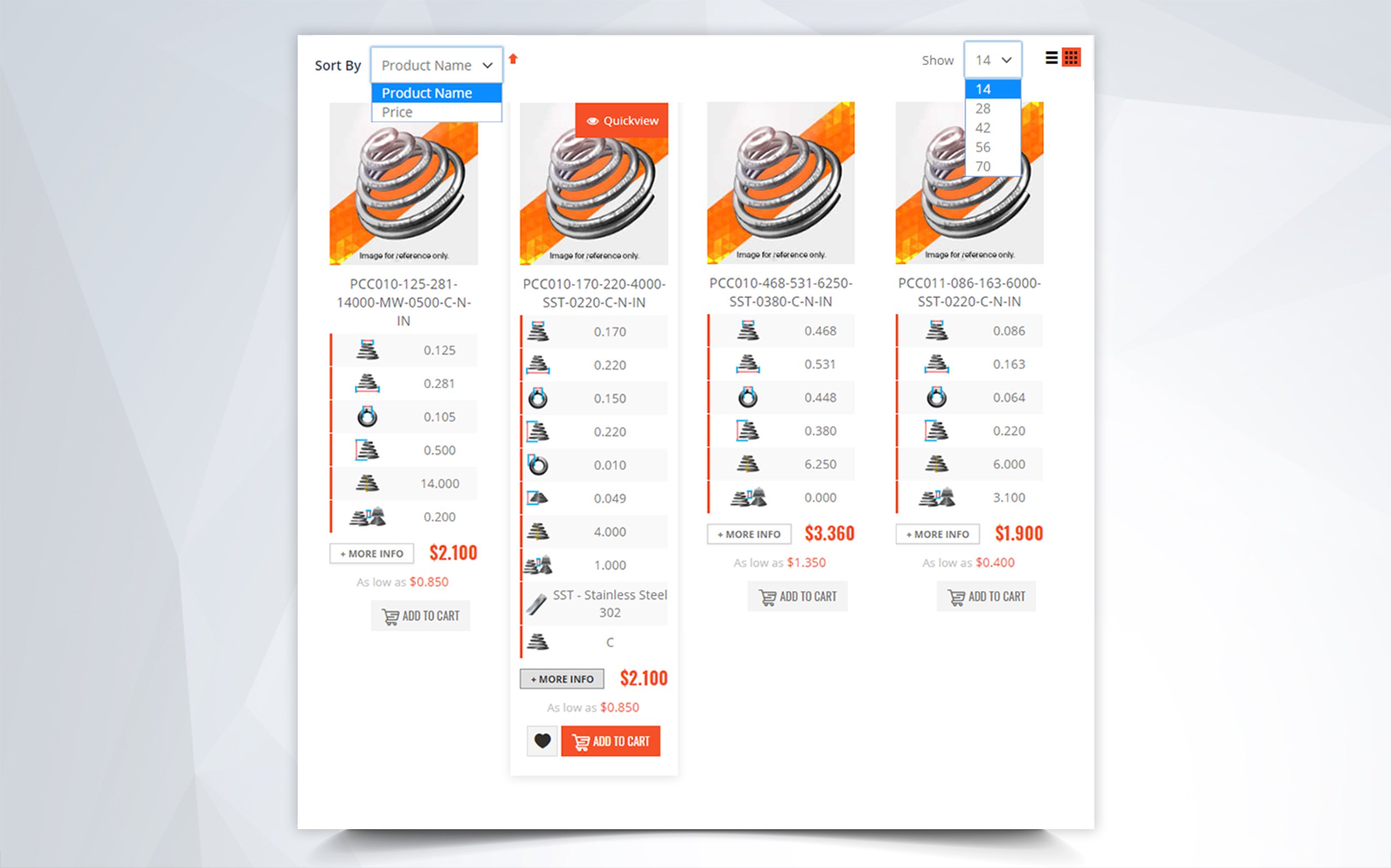

There are very special cases in which an application may require a spring to be compressed past the solid height its design allows. This is impossible with regular compression springs. However, it can be achieved with certain conical springs. Some conical springs can be manufactured with the ability to telescope, and therefore, reach a solid height the size of the wire diameter.

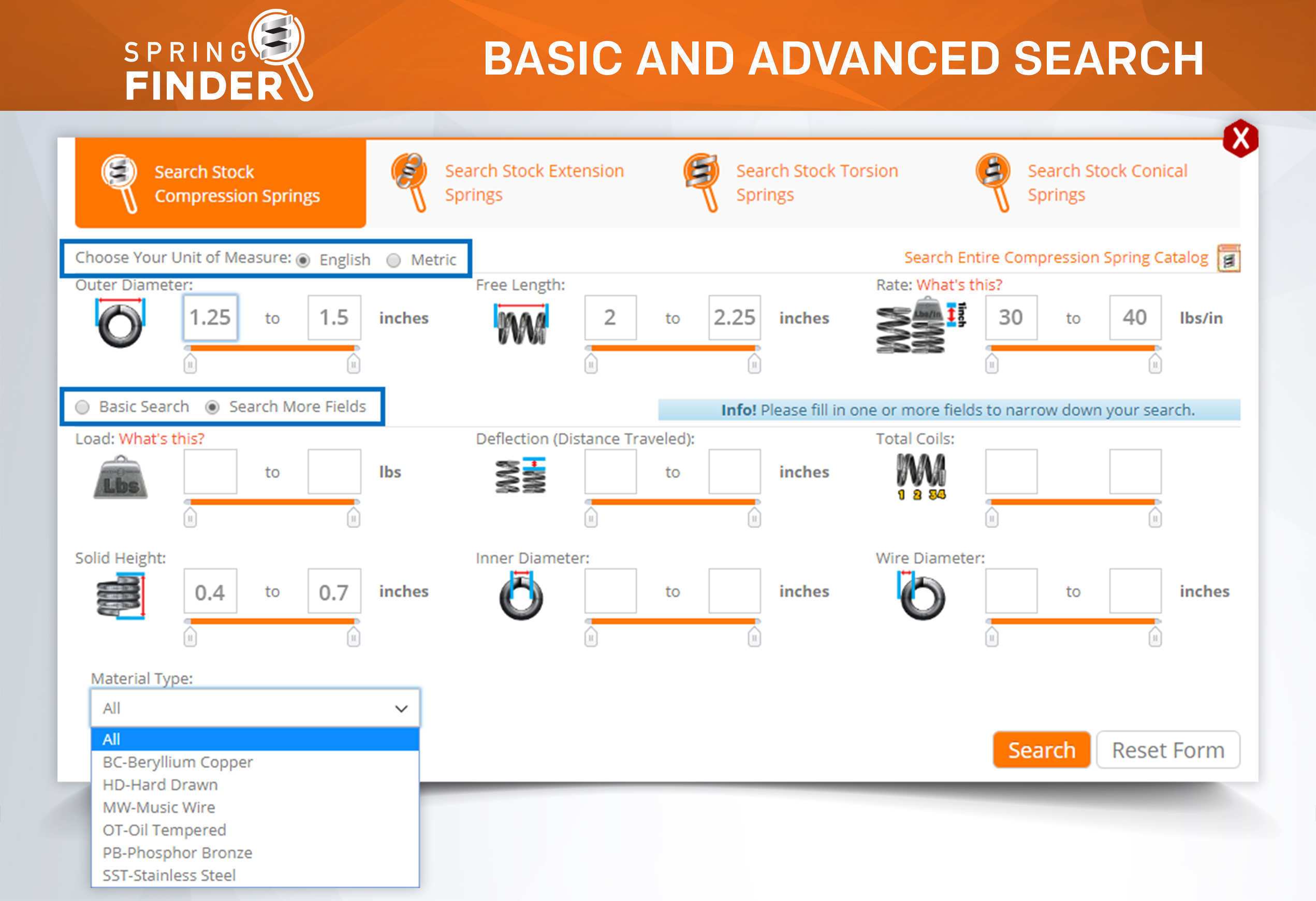

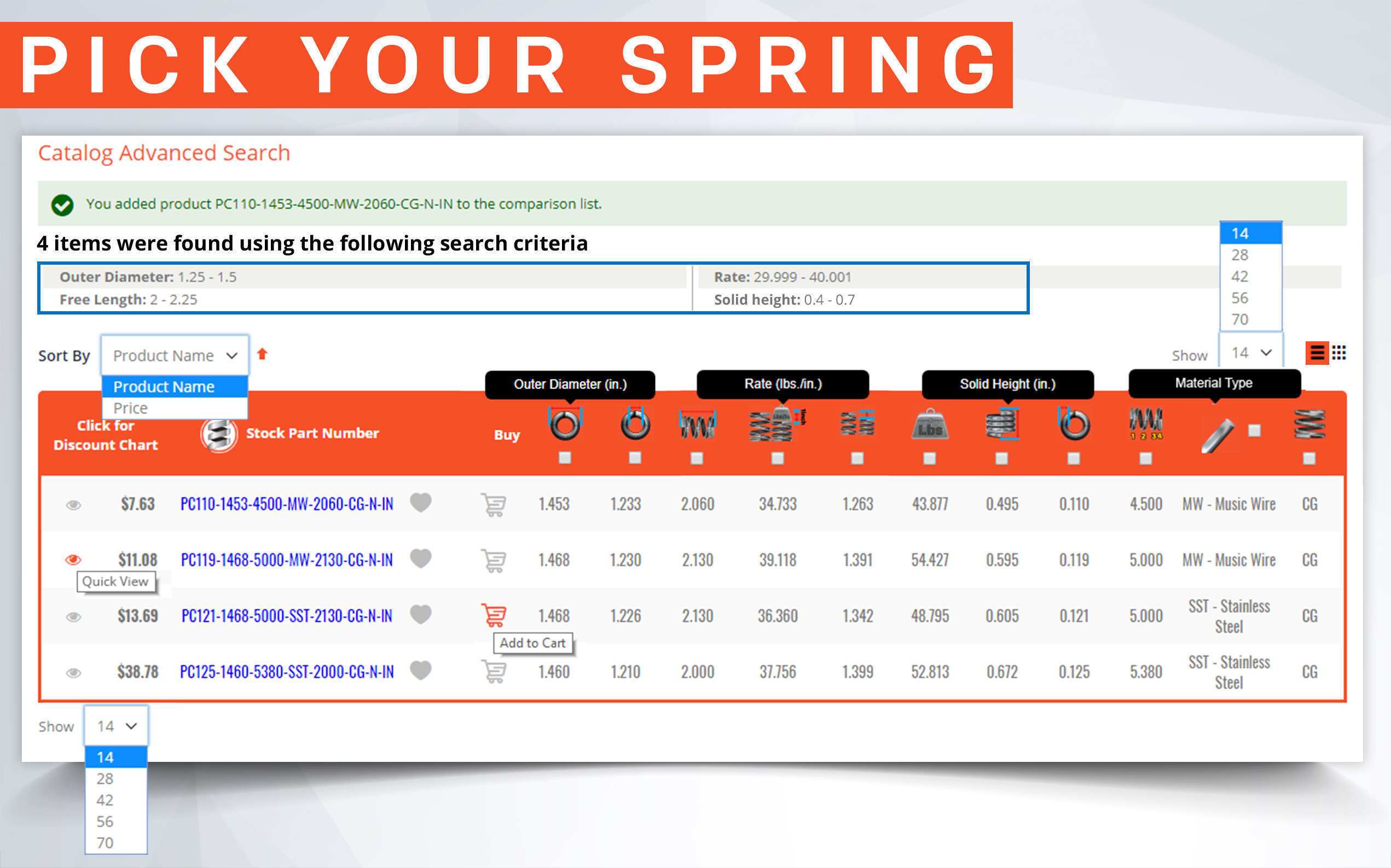

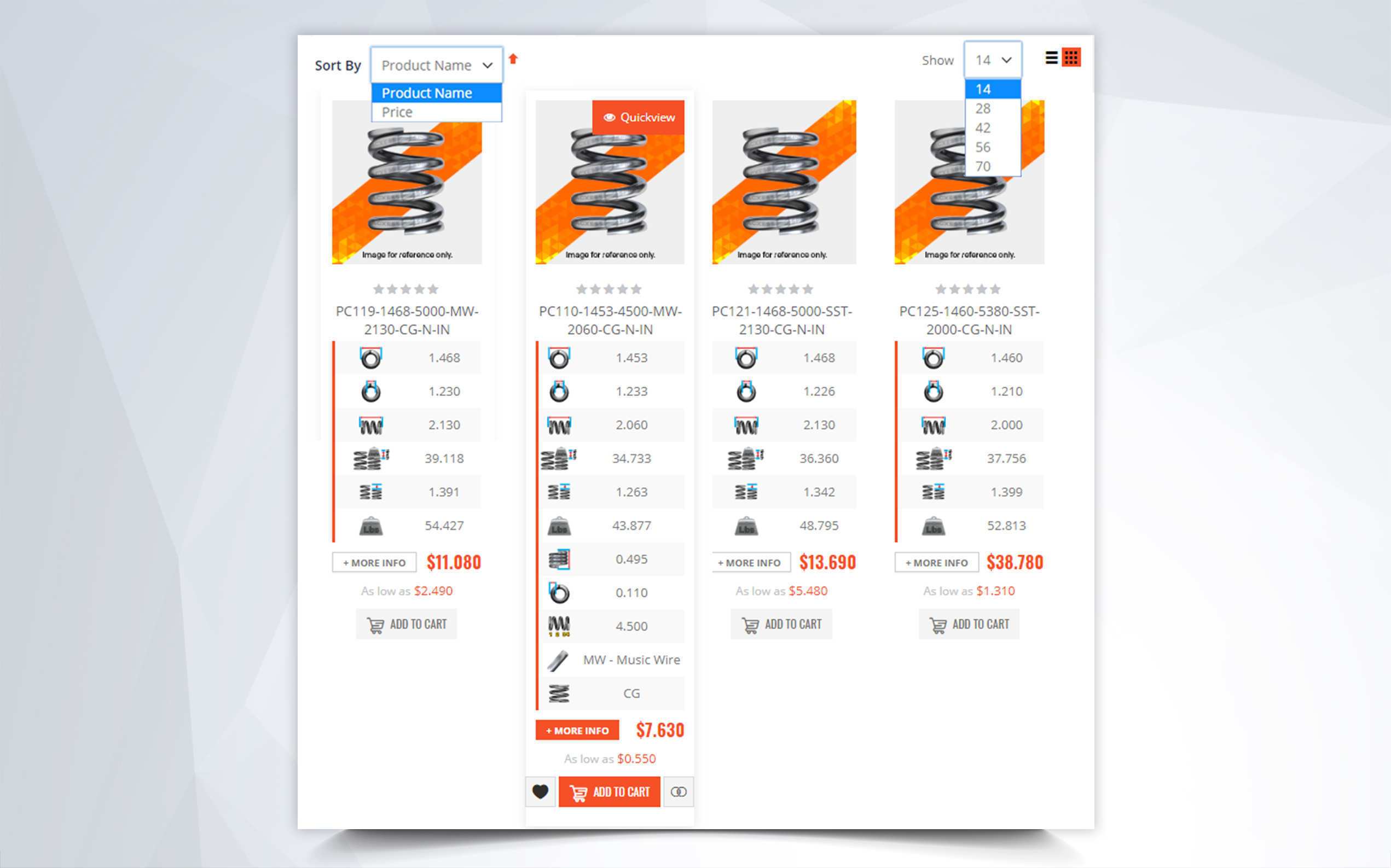

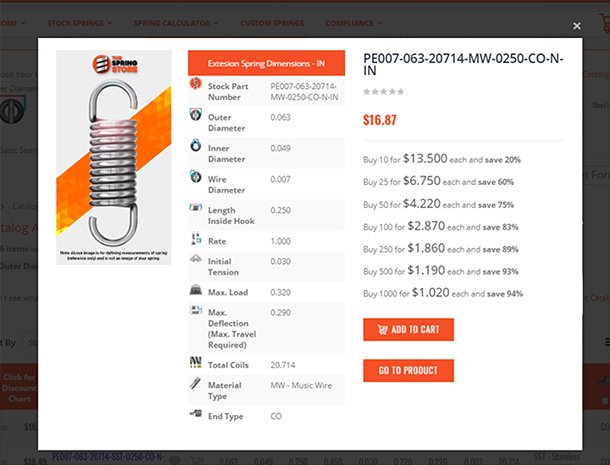

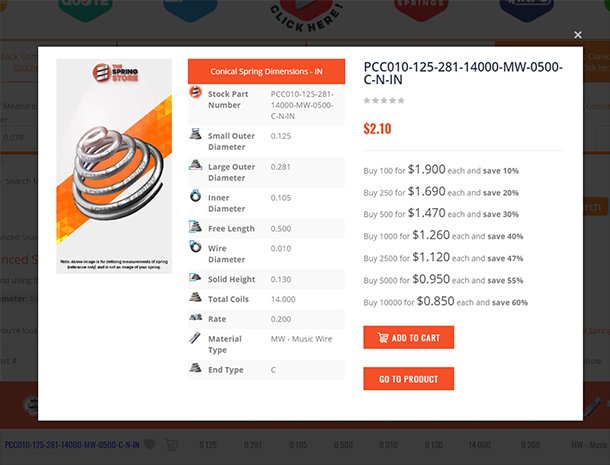

Let The Spring Store Take Care of It All

We usually provide all the technical information for each of our springs including free length, max deflection and solid height. When purchasing a stock spring, make sure that you verify all the specs, and that these match your needs. If you need additional assistance in purchasing the right stock compression spring contact us at: (951) 276-2777.