Specialty Springs - Buy Precision Springs Made To Order

Compression springs generate a constant force by charging back against loads that are placed on it. When a force or load pushes / compresses the spring down, the spring will push back against the force, and then return to it's original height when that force is removed. For more technical information on these springs visit our compression springs page at www.acxesspring.com/compression-springs.html

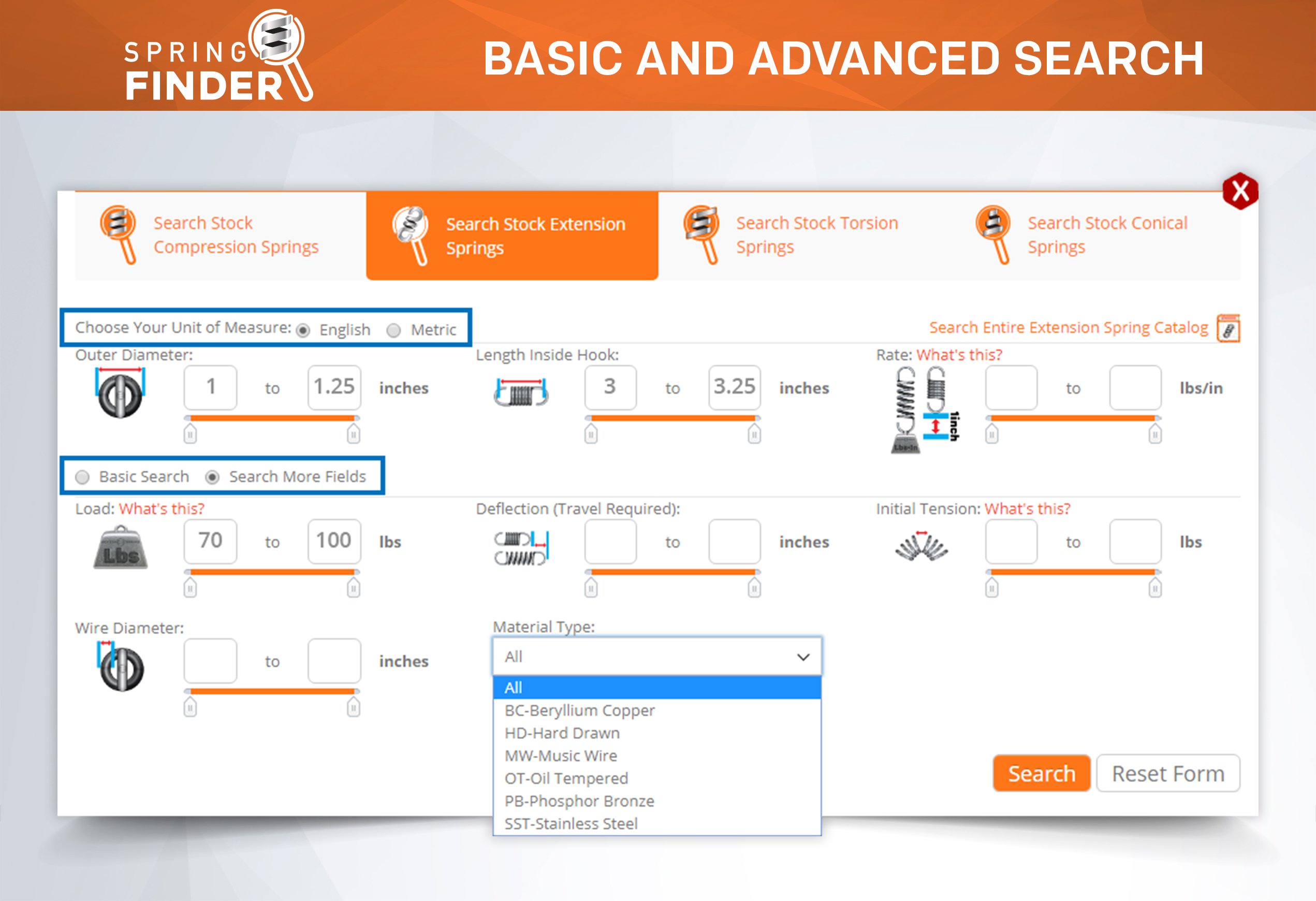

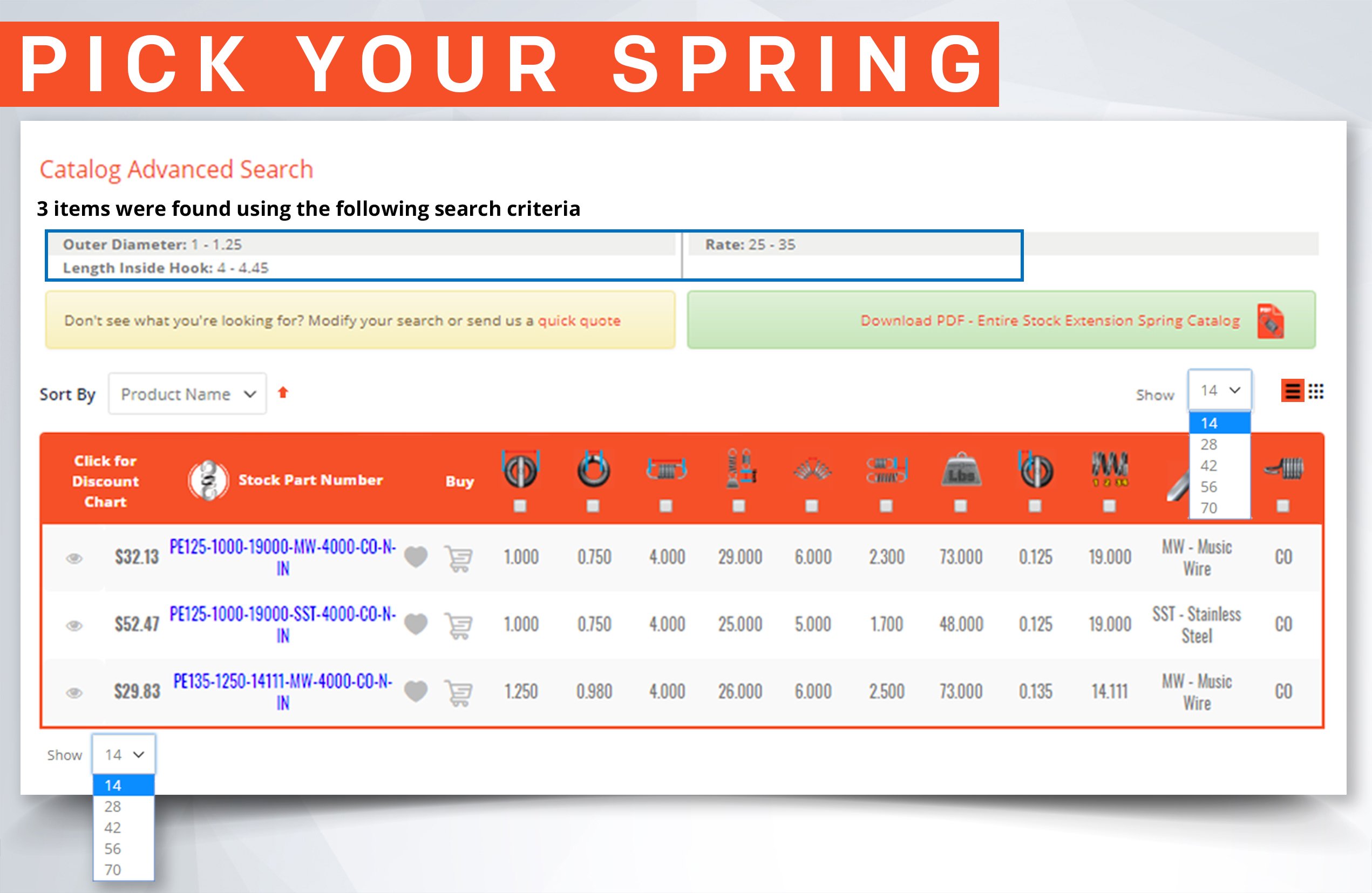

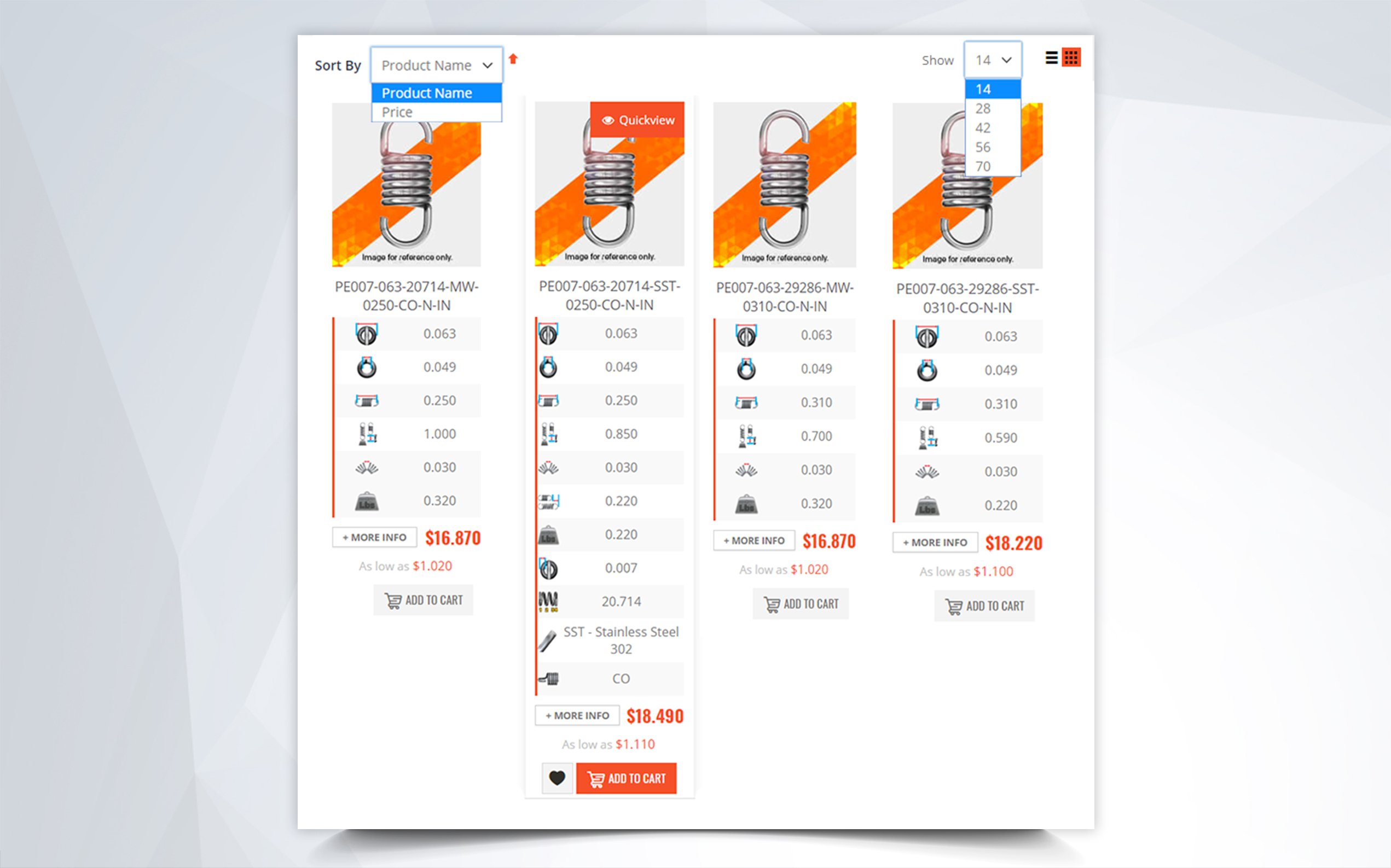

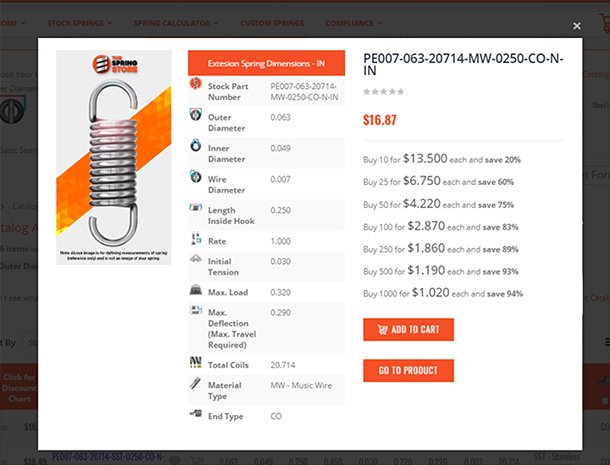

Extension/tension springs are the exact opposite of compression springs. These springs are helical wound coils wounded tightly together to produce tension and they usually have hooks on the ends. These springs are meant to exert extended force when the spring is extended from it's original length. For more technical information on these springs visit our extension springs page at www.acxesspring.com/extension-springs.html

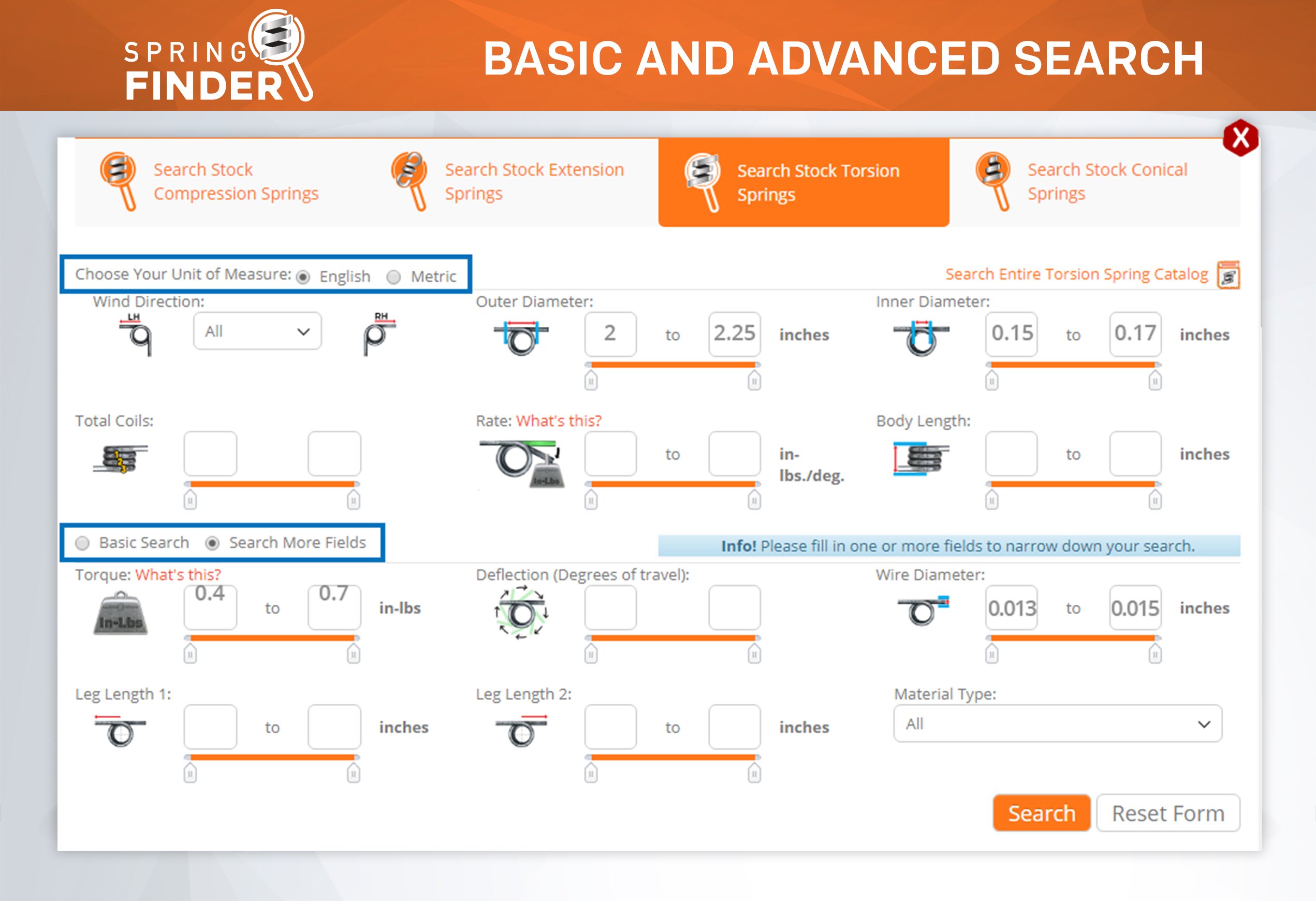

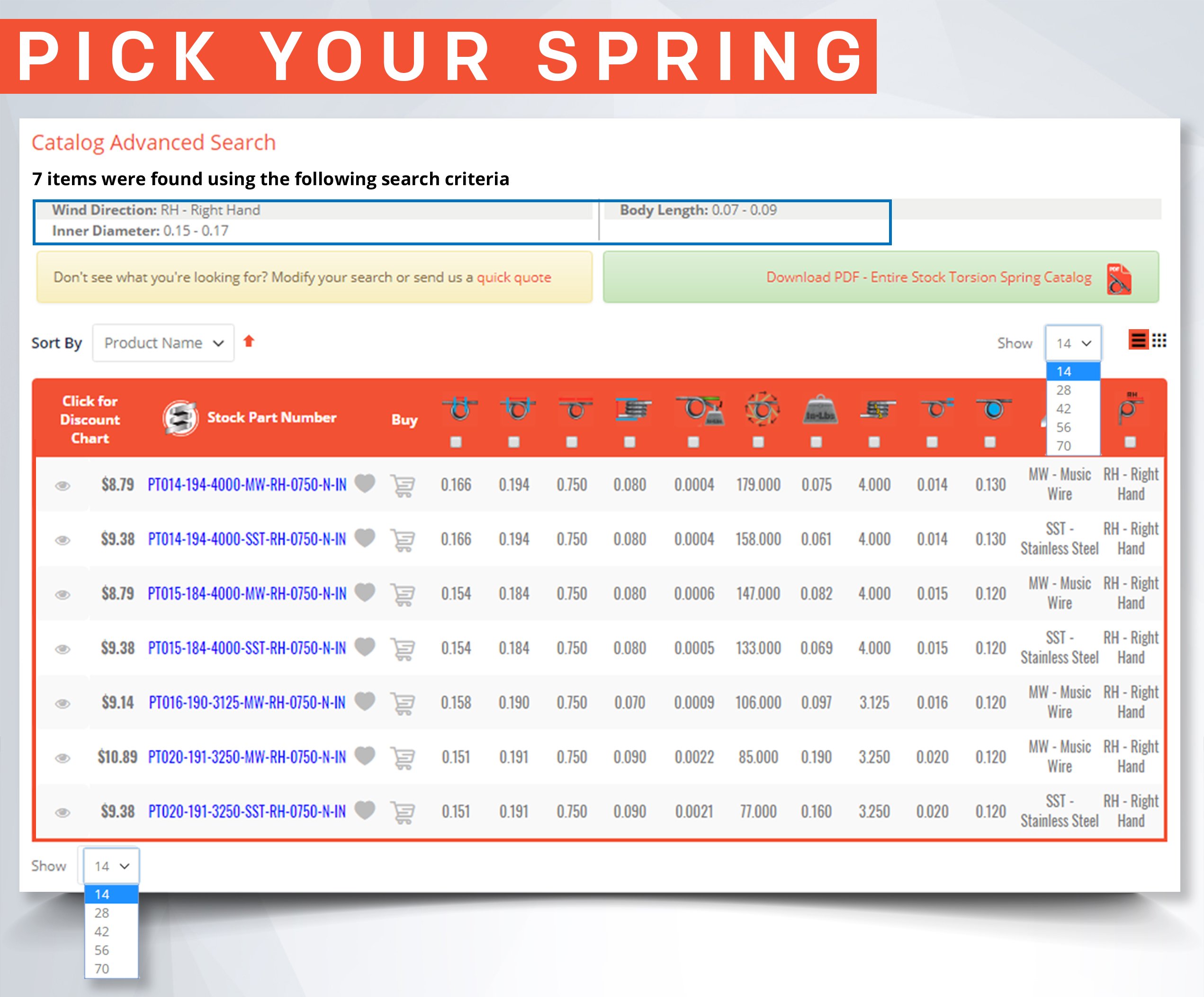

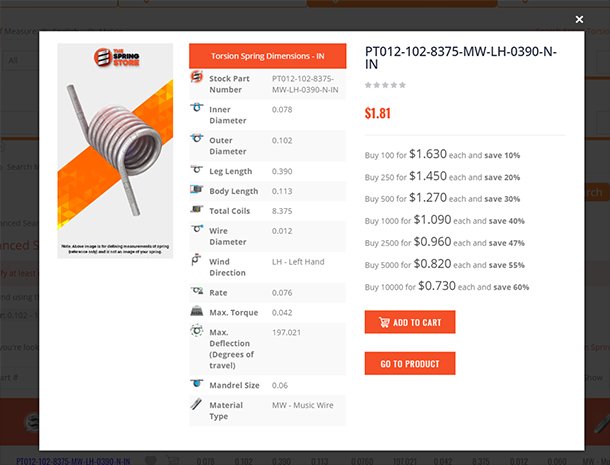

Torsion springs produce rotational and torsional forces. A prime example of the usage of a torsion spring is a torsion spring placed in a door hinge. When force is applied on the door to open it, the leg of the torsion spring pushes back against the hinge on the door causing it to return to it's original position. For more technical information on torsion springs, visit our torsion spring page at www.acxesspring.com/torsional-spring.html

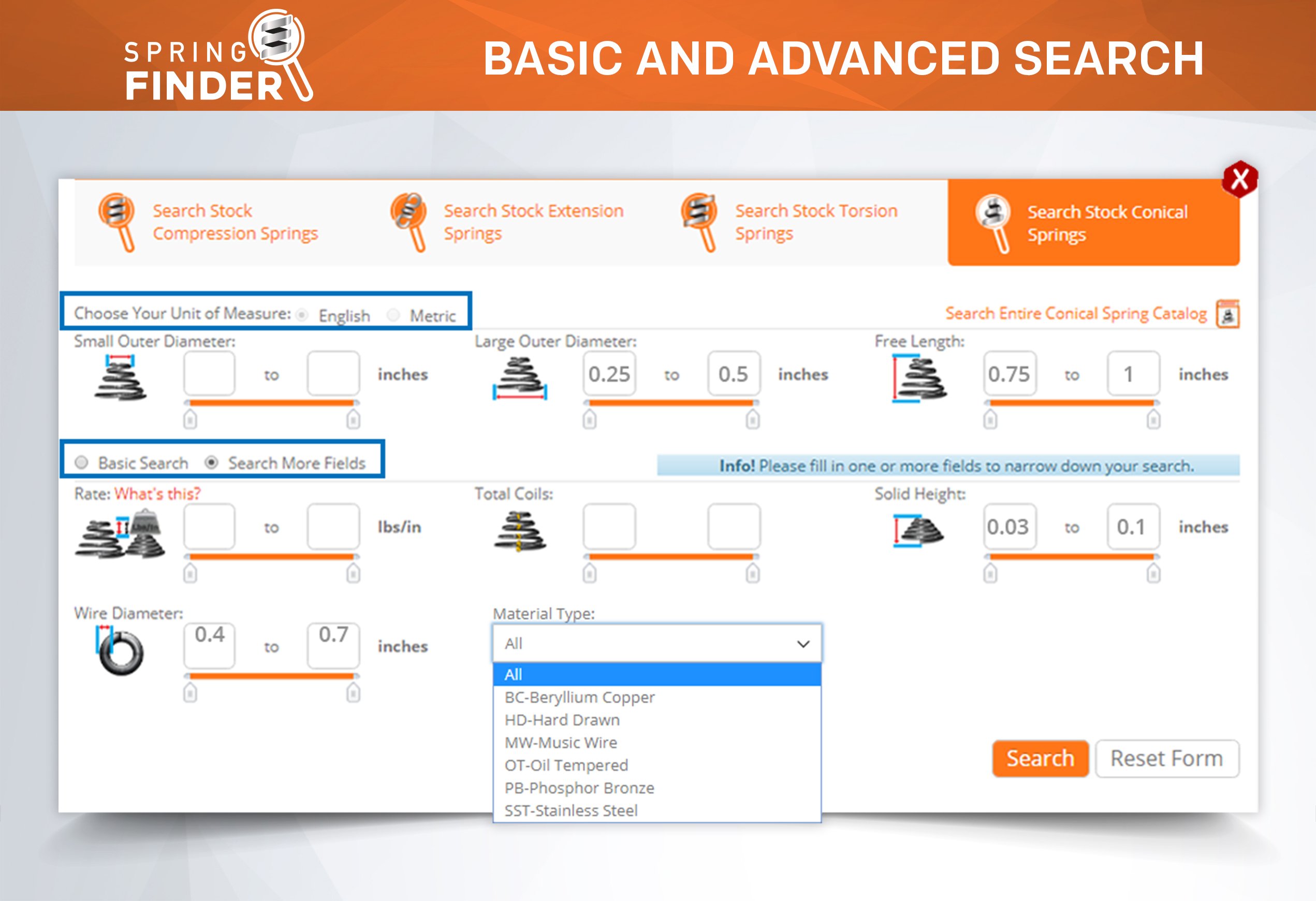

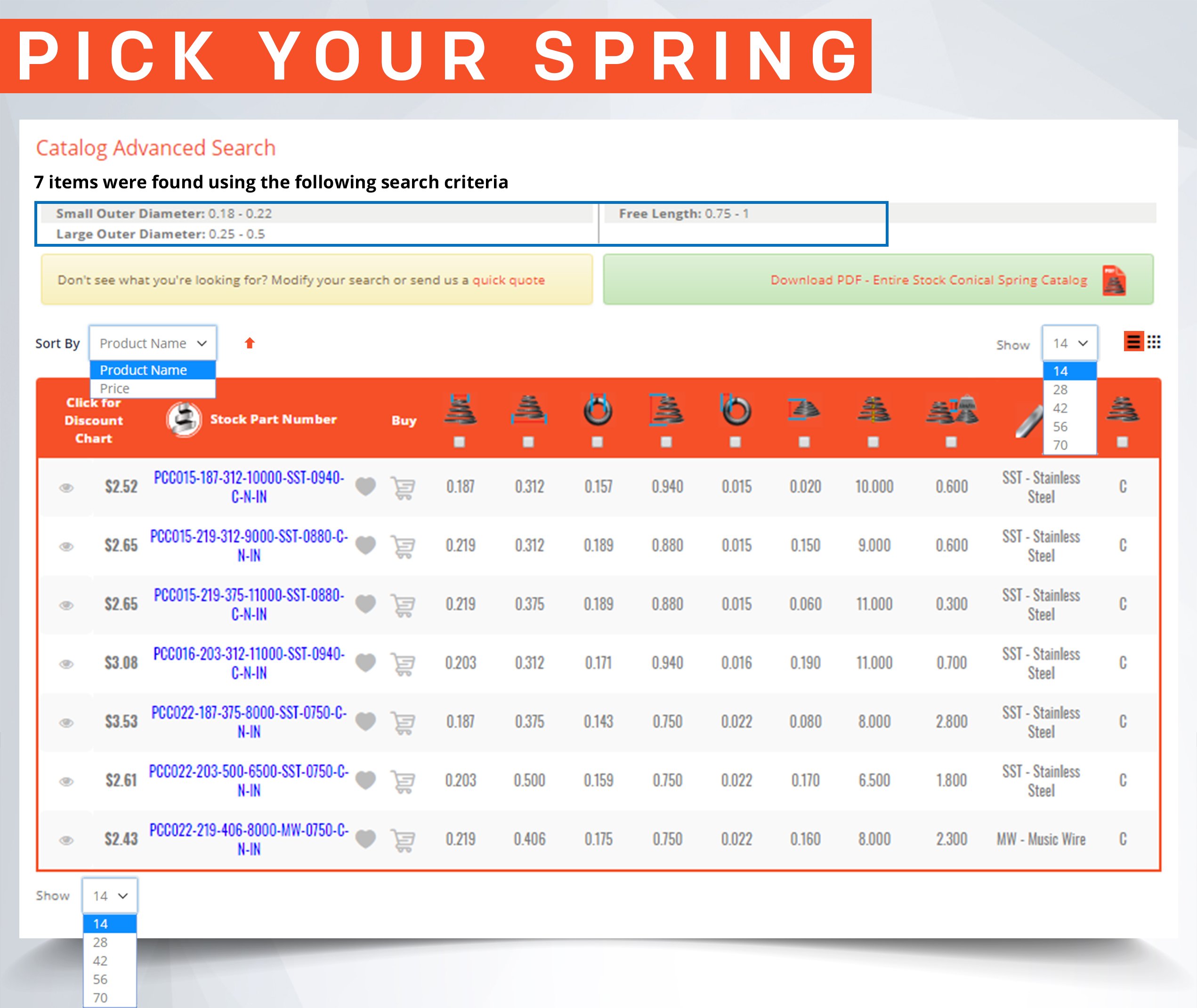

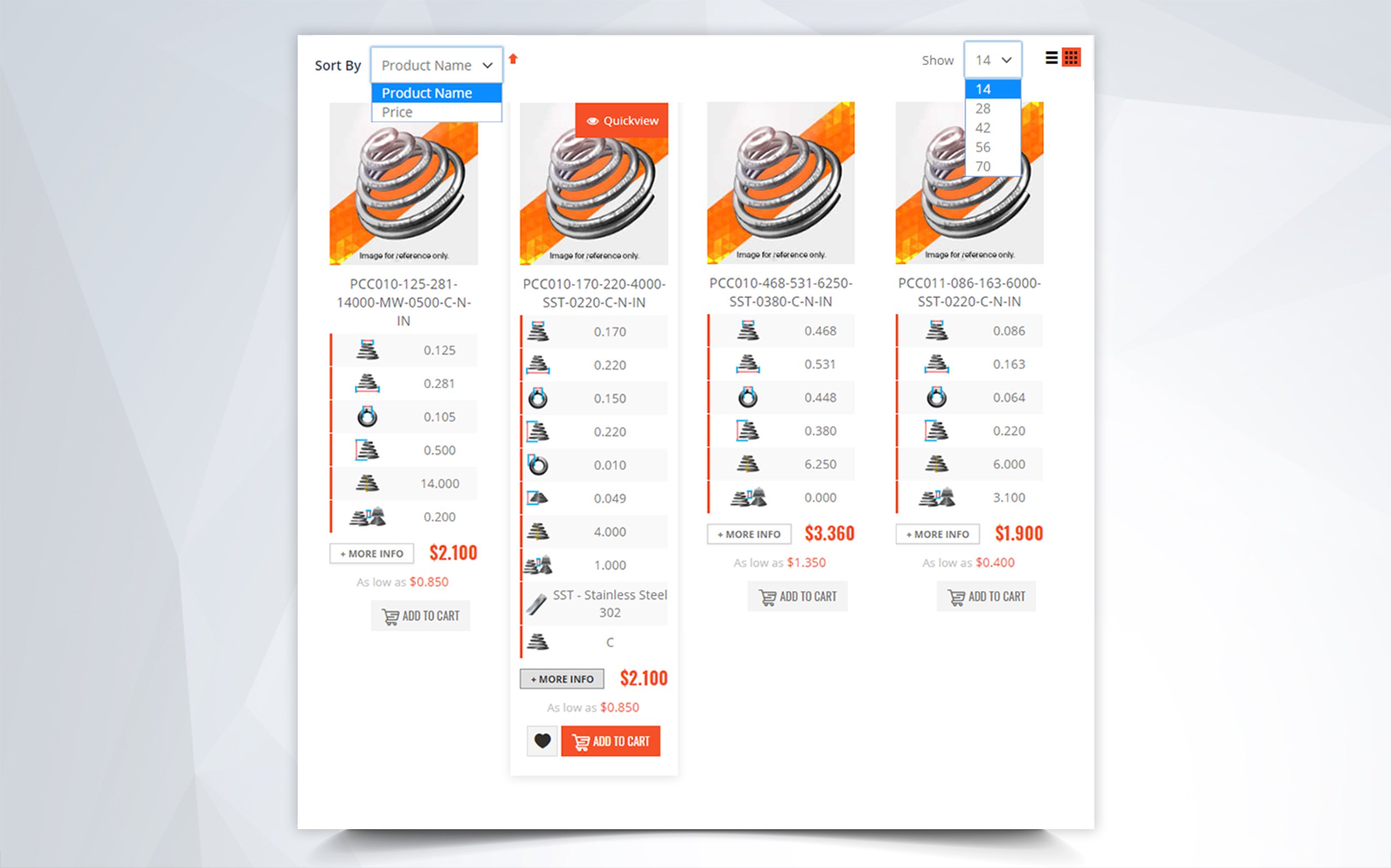

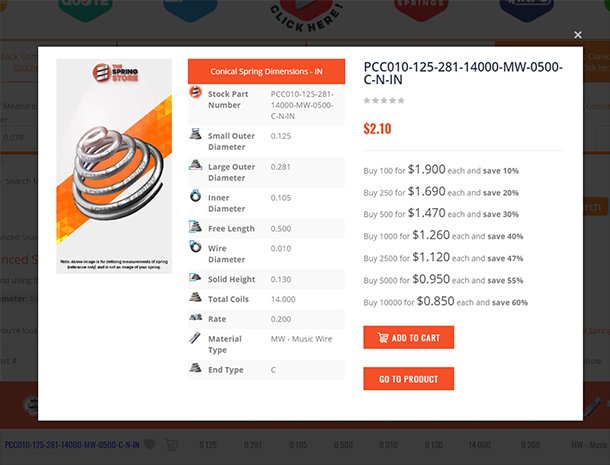

Conical springs are compression springs with the shape of a cone. These springs are used when more travel and stability is required out of a spring and due to it's physical dimensions, it cannot be met. The reason for this is because some conical springs have a telescope effect which makes their solid height smaller, providing more travel and stability when a regular compression spring bends/buckles. For more technical information, visit our conical springs page at www.acxesspring.com/cone-springs.html

Double torsion springs consist of two torsion springs wounded in different directions, united by an straight section between the two. The torque of these springs is calculated by adding the torque of one of the torsion springs to the other. For more technical information please visit our double torsion springs page at www.acxesspring.com/double-torsion-springs.html

Garter springs are made from a compression or extension spring having male cone shaped end and a female end. These ends are united; therefore forming the garter spring. There is many types of ends for different designs of these garter springs. The ends types are: connector ends, hooks connections, and tapered end connections. For more technical information, visit our garter springs page at www.acxesspring.com/garter-springs.html

Magazine springs are compression springs with an oval coil shape in order to fit into a firearm's magazine. This spring's outer diameter is measured separately because of the coils' oval shape. You must measure the short outer diameter as well as the long outer diameter. For more technical information, visit our magazine springs page at www.acxesspring.com/gun-springs.html

Barrel springs are also compression springs used when a certain compression spring design doesn't have enough stability due to it's physical dimensions which usually imply a small outer diameter and too long of a free length. When this is the case, the compression spring will buckle/bend when compressed. For this reason, the outer diameters of the ends coils are reduced forming a barrel spring and therefore providing more stability. For more information on barrel springs, visit our barrel spring page at www.acxesspring.com/barrel-springs.html

Wire forms may have many different uses and though they may be used to have a spring's function of compressing or extending, these don't necessarily have to be formed in coils. Wire forms can also be twisted to give you a torsion bar effect. For more information on wire forms, visit our wire forms page at www.acxesspring.com/wire_forms.html