Make Springs Stronger

How can you make a spring stronger?

This is a common question amongst the public. Sometimes, you’d prefer for your devices to be a bit stiffer or lighter but don’t know enough about springs to figure out how you can do that. In this article you will earn just how you can make your spring stronger or weaker.

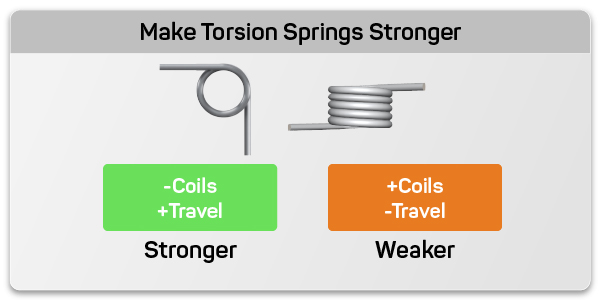

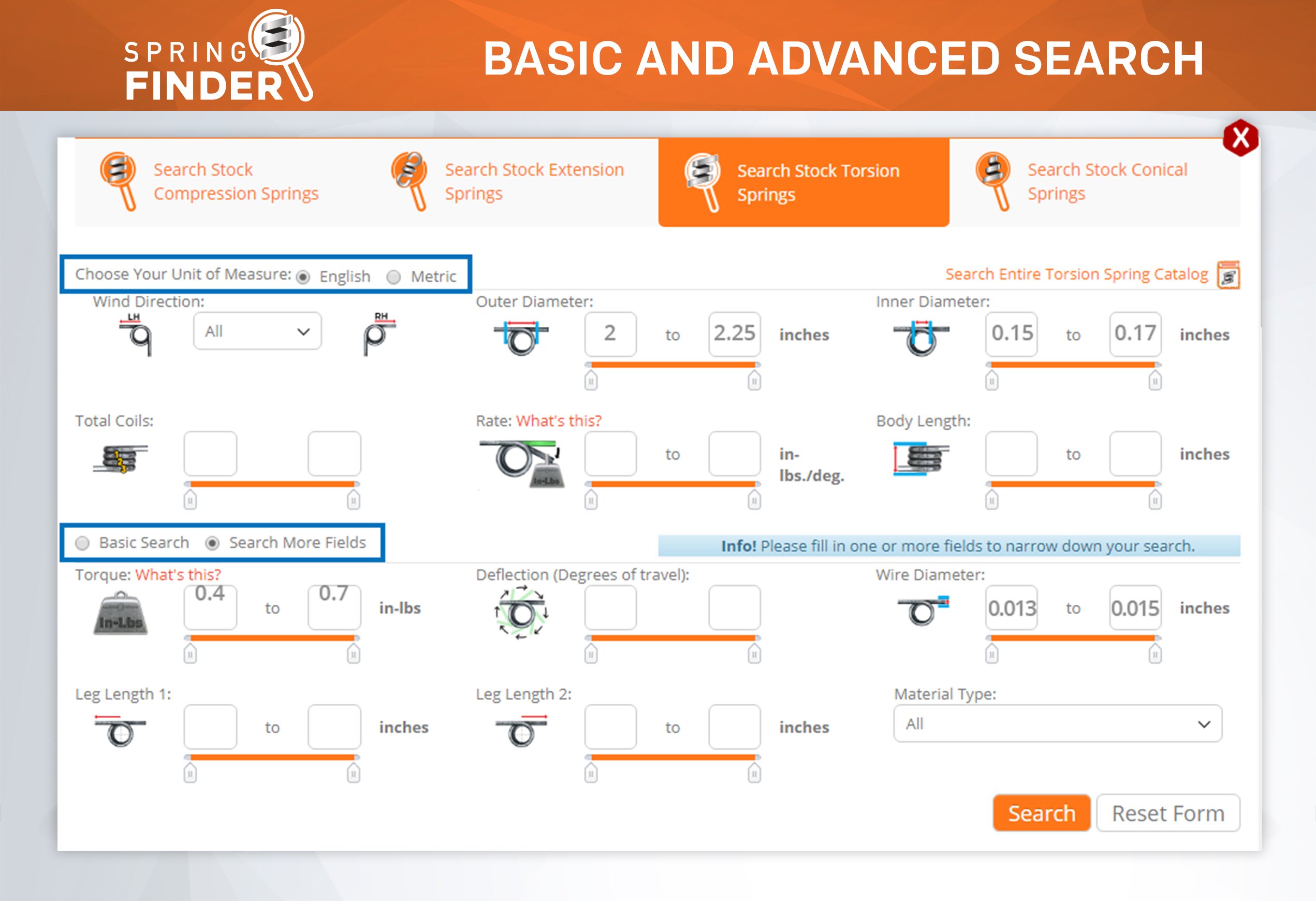

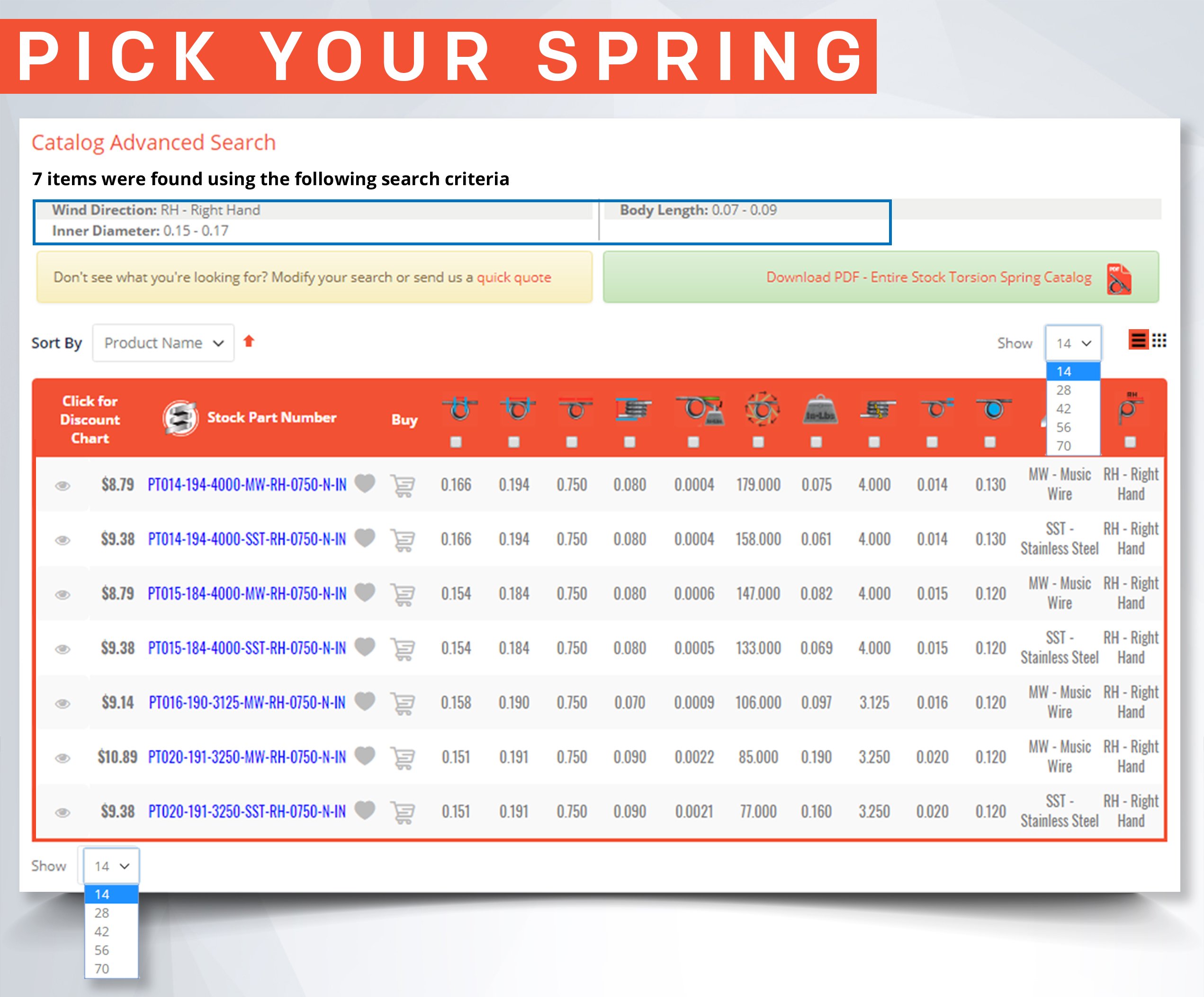

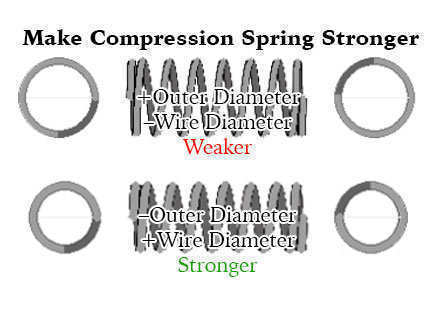

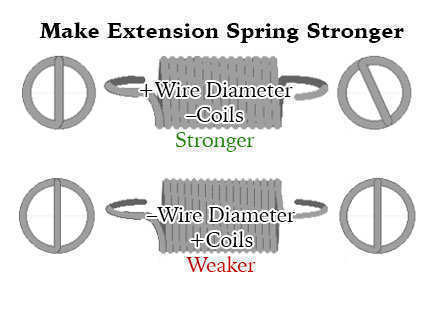

The diagrams to the right show what adjustments you must make to a spring for it to be stronger or weaker but I bet you’re wondering why some of these adjustments to the spring’s dimensions affect its force. Well, let’s begin with the increasing and decreasing of the wire diameter. If you make the wire diameter larger, you will make the spring stronger and if you make it smaller, you will make it weaker. This is because, by making the wire diameter larger, you are also making the spring’s coils tighter which reduces the spring index. The opposite effect is done when you make it smaller, the spring index increases so it isn’t as tight and it is under less stress. This adjustment will not only affect your spring’s force but it will also affect its elastic limit like it does when adjusting the outer or inner diameter. Keep in mind that adjusting the wire diameter will affect the solid height on compression springs and the body length on extension and torsion springs.

When you adjust the outer diameter to be stronger, you must make it smaller. To make it weaker, you must make the outer or inner diameter larger. Because the wire diameter remains the same, we get the same effect out of it as we did when adjusting the wire diameter. If your coils are tighter, you have a smaller index, which gives you more force. If you make the coil diameter larger, your spring index is bigger thus making your spring weaker. The way this affects the elasticity of your spring design is because springs with reduced spring indexes are under more stress than springs with average or large indexes. This means that if you reduce the coil diameter or increase the wire diameter, your spring will be stronger thus making it more difficult to compress.

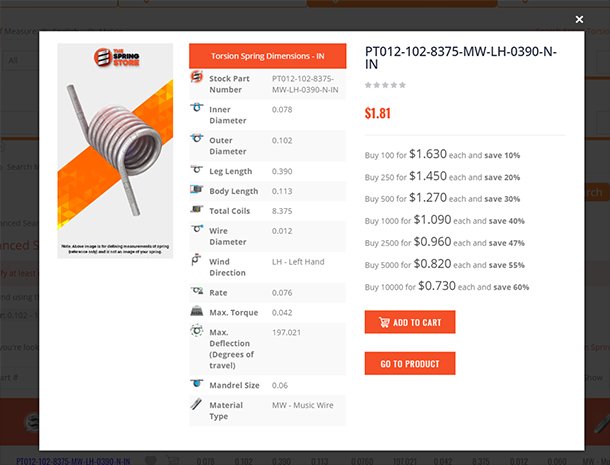

In these cases, what you want to do is make adjustments everywhere on your design so, not only are you able to get the force you need but you also get the travel. Another adjustment you can make is taking out or adding coils. When you take coils out, the remaining coils will have more pitch in between them which means it will take more for them to compress. This is in the case of a compression spring. In the case of an extension or torsion spring, there are less coils working together to provide that extension or torque so, again, you spring will be stronger, but it will be under more stress. On the other hand, if you add coils; you compression spring will have less pitch in between its coils and your torsion or extension spring will have more coils working together to provide you with the elasticity you need.

To get the correct design, you want to mix these procedures. Maybe make the outer diameter smaller to make it stronger but also add a coil or two to release stress. You may also make the wire diameter larger to a point where it is stronger than you need but then make the outer diameter a bit larger to release tension and also achieve more travel. If you aren’t able to meet your working loads with these adjustments, the next step is to get more force out of generating more travel.

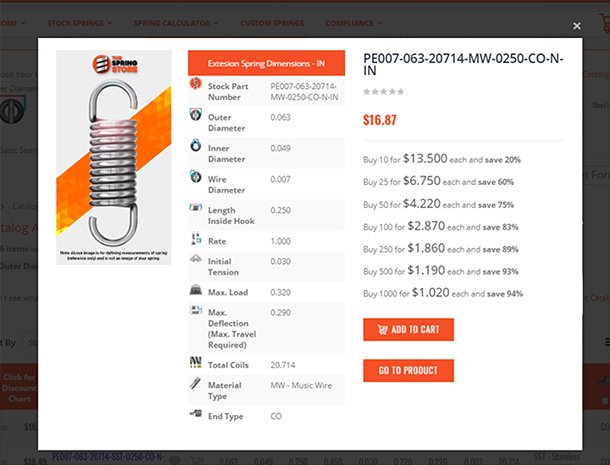

To generate more force out of producing more travel, the procedures are different for each spring type. For compression springs, you must make sure that your spring has a true maximum travel higher than the maximum travel considering solid height. This will allow for you to make the spring longer thus having to travel more in order to meet your desired loaded height. In the case of an extension spring, you must make the length inside hooks shorter which will also affect the body length thus taking out coils as well so be very cautious with this procedure. In the case of a torsion spring, in order to produce more torque through more degrees of travel, you must adjust the free position further away from the direction in which it will travel.