Torsion Spring Applications

Torsion Springs at Work

Torsion springs are less common than compression springs and extension springs. However, they play a valuable role in the execution of certain movements within a device. Unlike compression and extension springs, torsion springs have legs on which a force or load is placed. A torsion spring’s job is to provide a rotational force, in the opposite direction, when a load is placed on one or both legs.

How Torque Springs Work

The force placed on the torsion spring’s legs creates a movement (torque or travel) to a desired distance in degrees of rotation. Basically this means that when a load is applied to the spring’s legs these create a torquing motion that causes a desired action.

For example, in a clipboard when you clasp and press the top part of the clip you place force on its legs. This causes the torsion spring inside to torque (move in a rotational force) and as it does this, it opens the bottom part of the clip in order for you to place the papers inside the clip. When you stop pressing the top of the clip, you release the force you placed on the legs. The torsion spring then returns to its original position, clasping the papers that were placed in the mouth of the clip.

Torsion Spring Uses

There are different uses for torque springs, from simple apparatus applications such as doors and gate hinges to life-saving devices in the watercraft and outdoor sport industries. Today we will discuss both well-known applications as well as not so commonly-known uses for torsion springs.

Spring Applications in Doors and Gates

Torsion springs are found in rear trailer doors and gates. They assist in lifting the door or gate by taking most of the weight off the door or gate. This makes it lighter and easier to close/open without having to carry the weight of a very heavy gate yourself.

Restaurant doors also use torsion spring loaded hinges to help the door swing back closed. If you ever saw a waiter come out of the kitchen from a restaurant and the door close behind them you can bet that door most likely had spring loaded hinges that depend on torsion springs. This means that the force placed on the door in order for it to open places a load on the torsion spring’s legs that is then released as the person steps through the door and stops placing force on it. When that happens the spring leg’s torque back to their original position, forcing the door to pull shut.

Coil Torsion Springs in Watercraft Step

Torsion springs can be made of different material types. When they are placed in humid environments they need to be made of stainless steel in order for them to not corrode. You can find stainless steel torsion springs on personal watercraft boarding steps. Boarding steps are life saving devices on personal watercraft vehicles because they allow the rider to board the craft easily after falling off the craft or riding for hours. When the rider is tired or there is turbulent waters the step becomes crucial to their survival to be able to reboard the craft.

The key to making the watercraft step such a valuable tool for riders are stainless steel torsion springs that allow the step to be automatically retractable. The step becomes automatically retractable when pushed down by the weight of the person trying to board the watercraft. This way when a person falls off and tries to get back up on the watercraft the pre-loaded torsion spring inside the bracket is pushed down and the torsion spring’s torque helps lift the step back up. Once the user boards the craft and is no longer placing the weight or force into the step it returns to its upright original position.

Torque Springs in Rock Climbing Camming Device

Another important life-saving device that is used in extreme sports is the camming device for rock climbing and mountaineering protection. Torsion spring-loaded camming devices are also known as SLCD, cam or friend. These cam devices are rock climbing protection equipment that depend on torque springs to help their users stay safe while completing this high-risk outdoor activity.

When a person is climbing up a rocky mounting, the “Cam” is inserted into a crevice or gap in the face of the rock that is being climbed upon. When the person releases the grip and the torsion spring releases its stored energy, the cams spread apart and grips the inner walls of the crevice in the mountain with enough energy to allow the rock climber to hang from the cam.

This device consists of two, three, or four cams mounted on a common axle with a preloaded torsion spring and two adjacent axles, so that pulling on the axle forces the cams to spread farther apart.

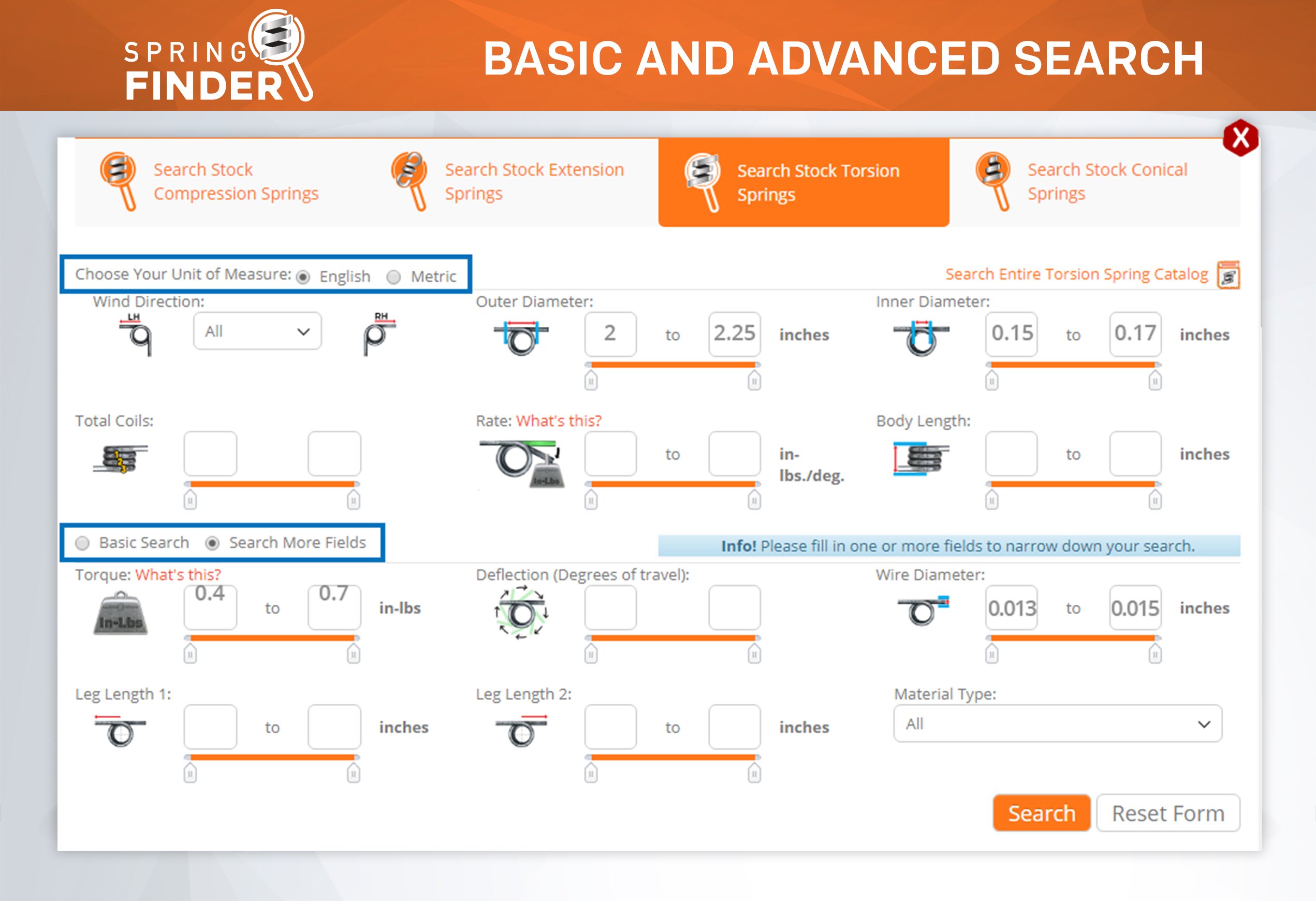

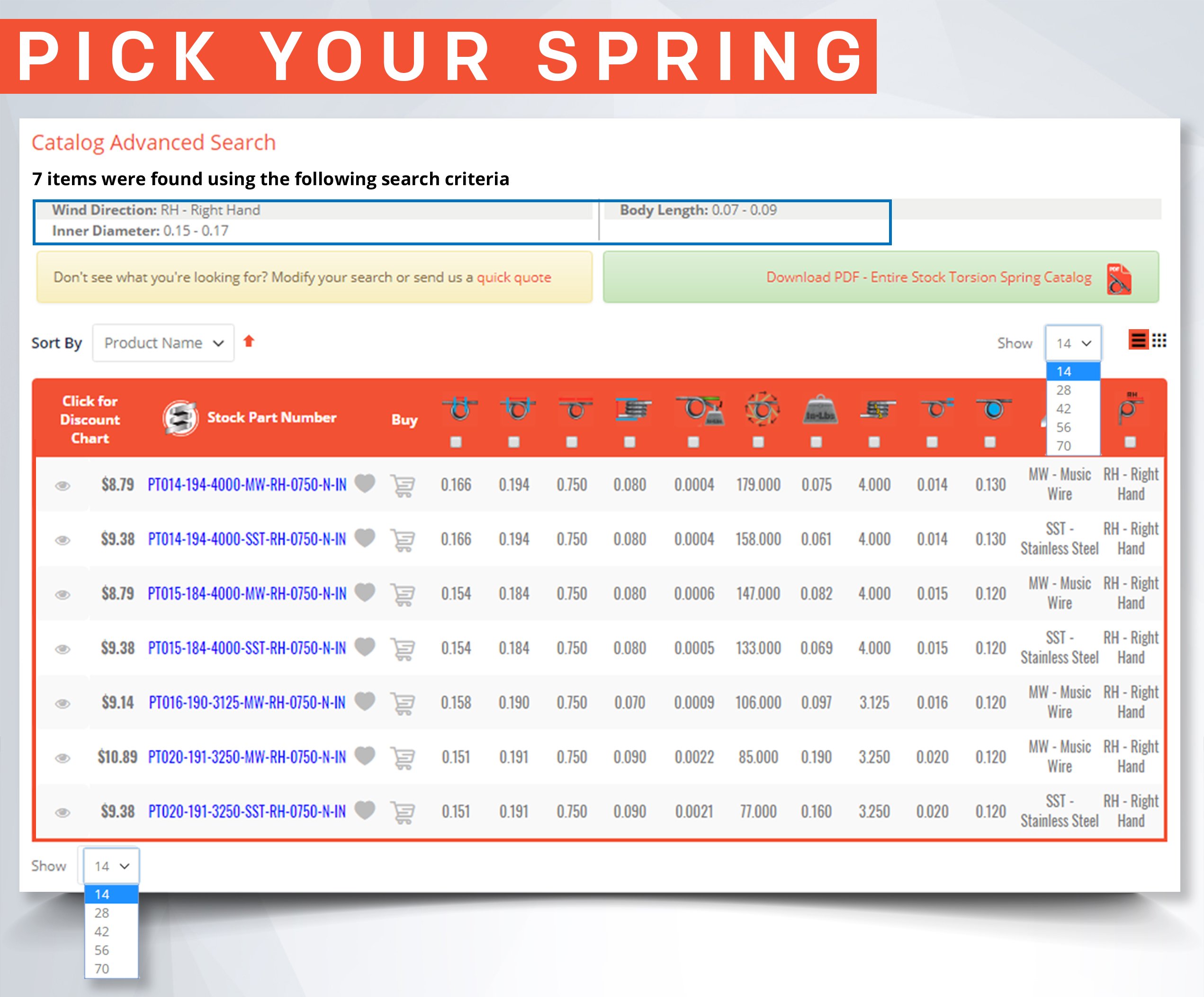

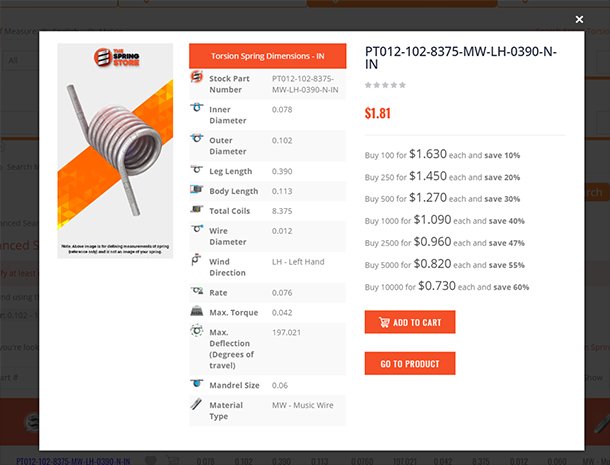

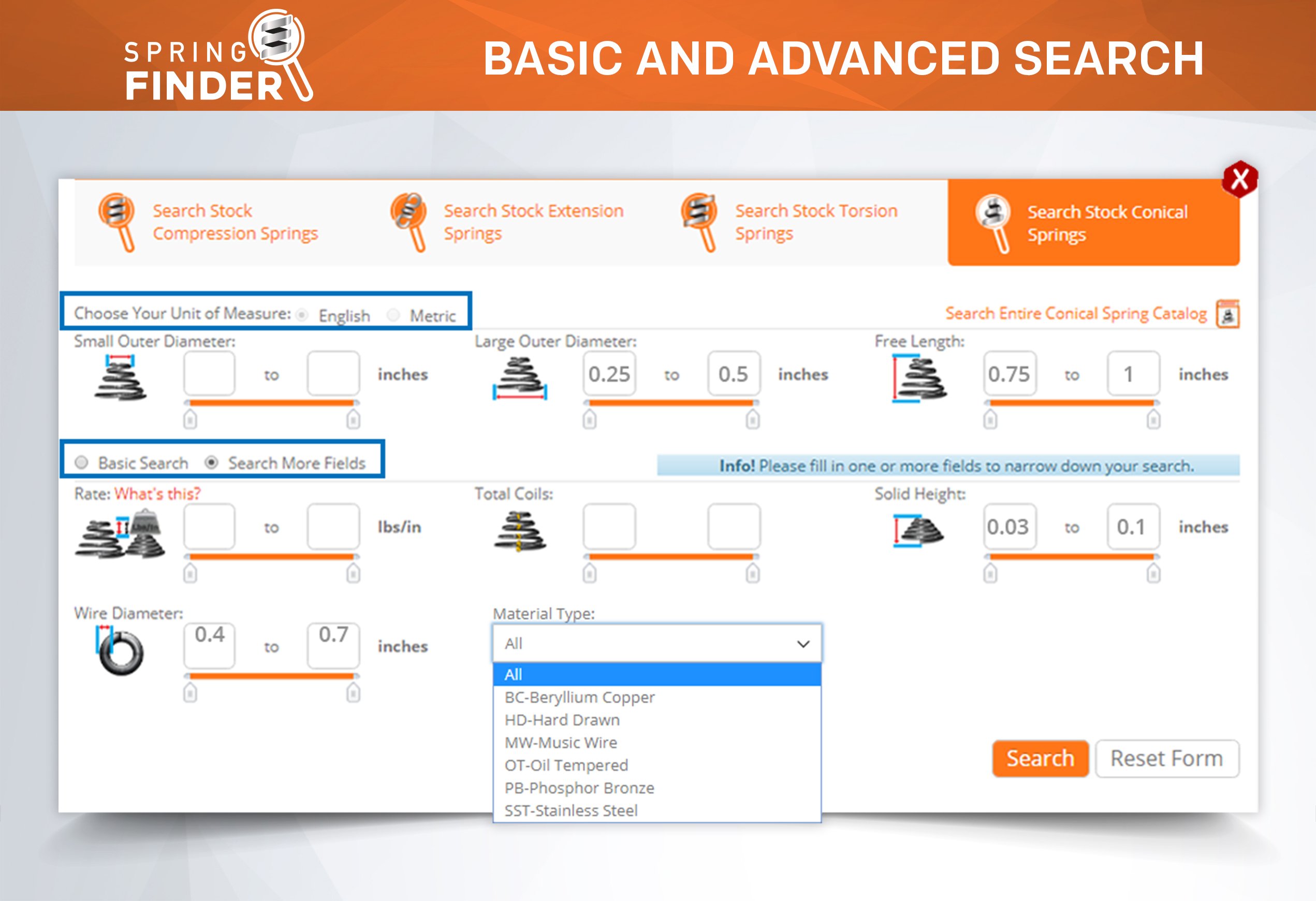

High Quality Stock Torsion Spring Replacements

As you can see, many torsion spring applications are actually life-saving devices. This is why at The Spring Store we make sure that all our stock torsion springs meet very high quality standards. It is important to us that each spring we make and sell is designed for the correct environment and use, whether it is a replacement torsion spring or prototype stock spring. If you have any questions or concerns about how adequately purchase a torsion spring for your application, please contact us directly at:(951) 276-2777