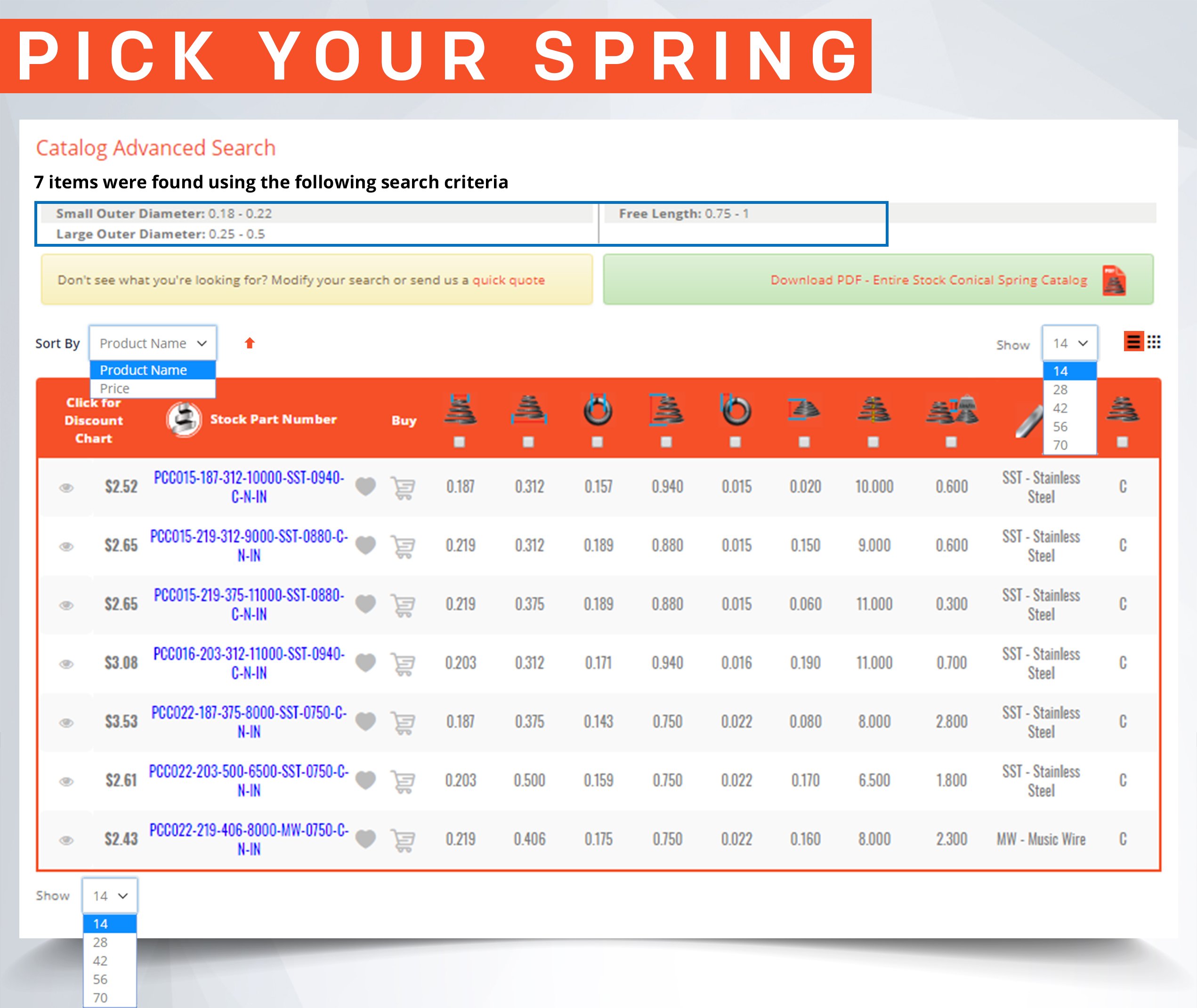

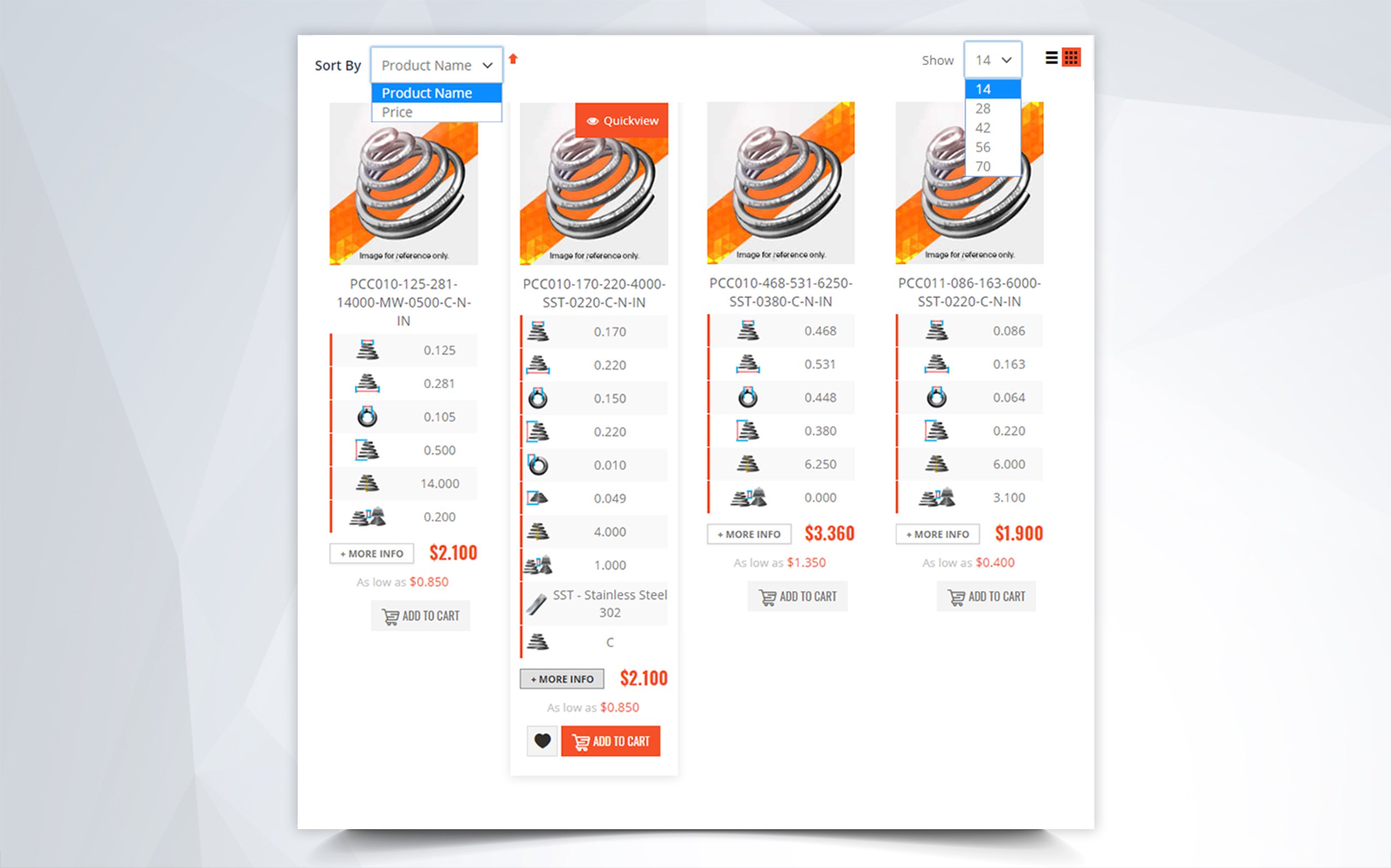

Spring Dimensioning and Tolerancing

Definition: System used when generating a spring design on a blueprint specifying the geometric dimensions. Tolerancing the dimensions of your spring will show you the limitations around it as well as the room you have to make modifications.

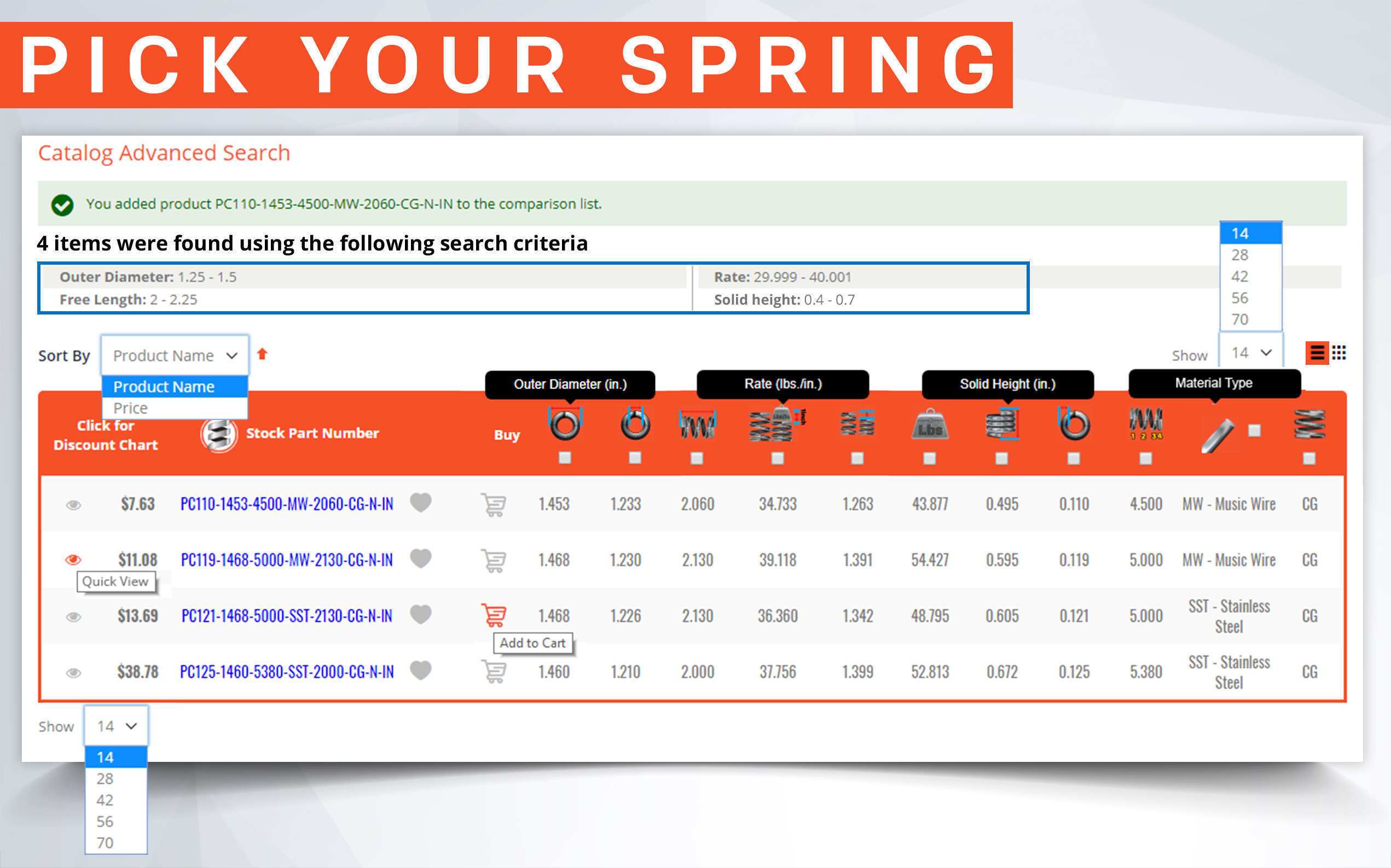

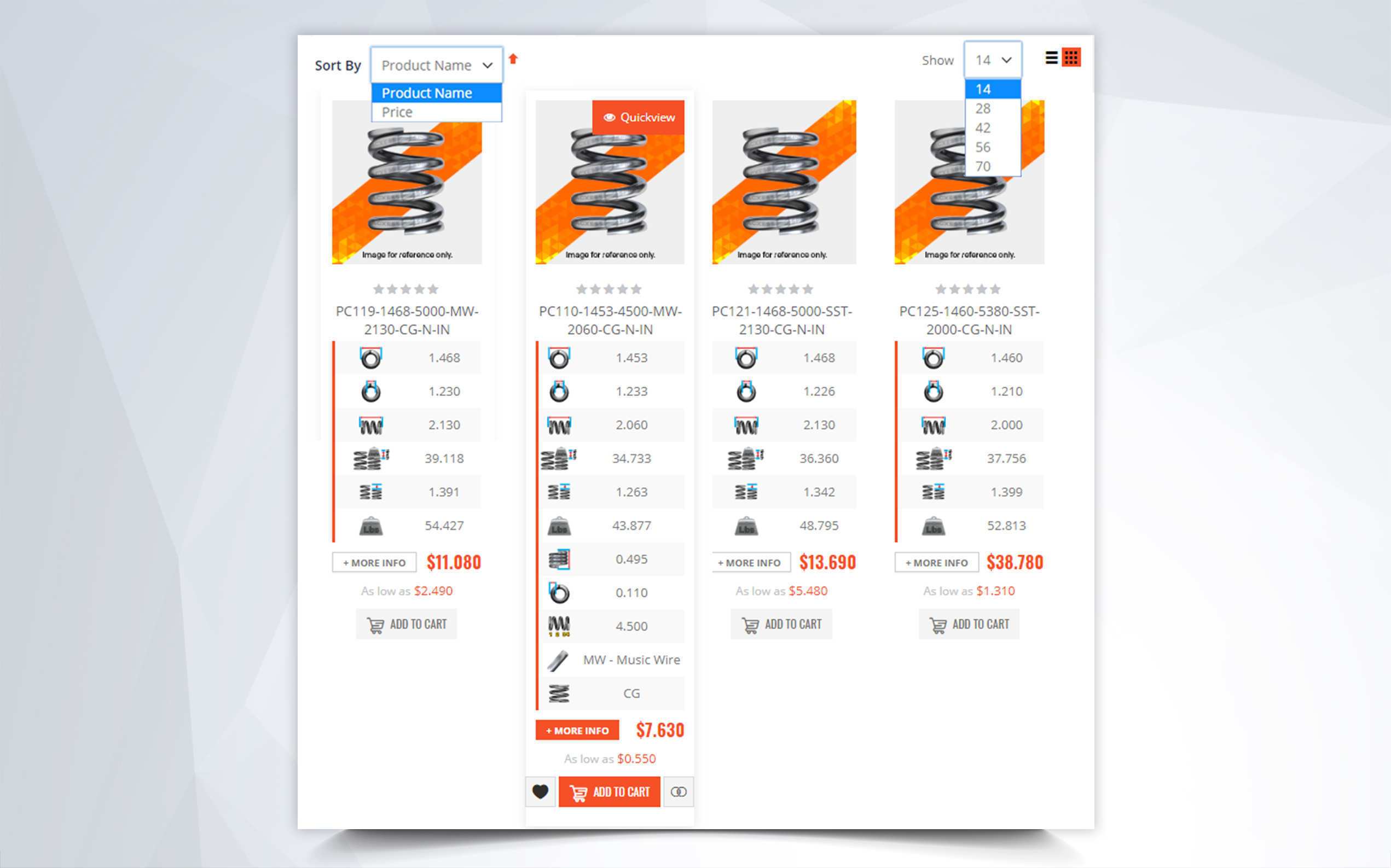

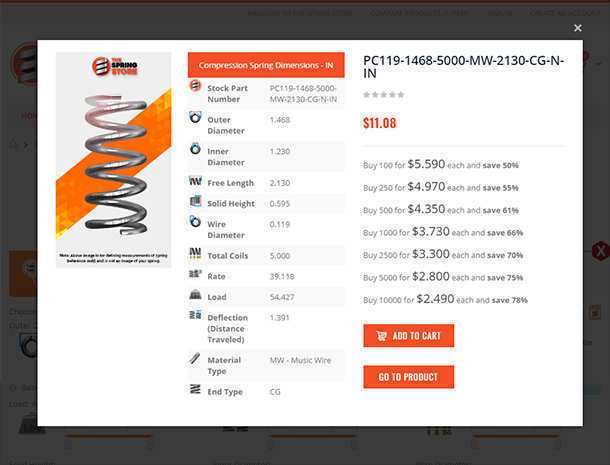

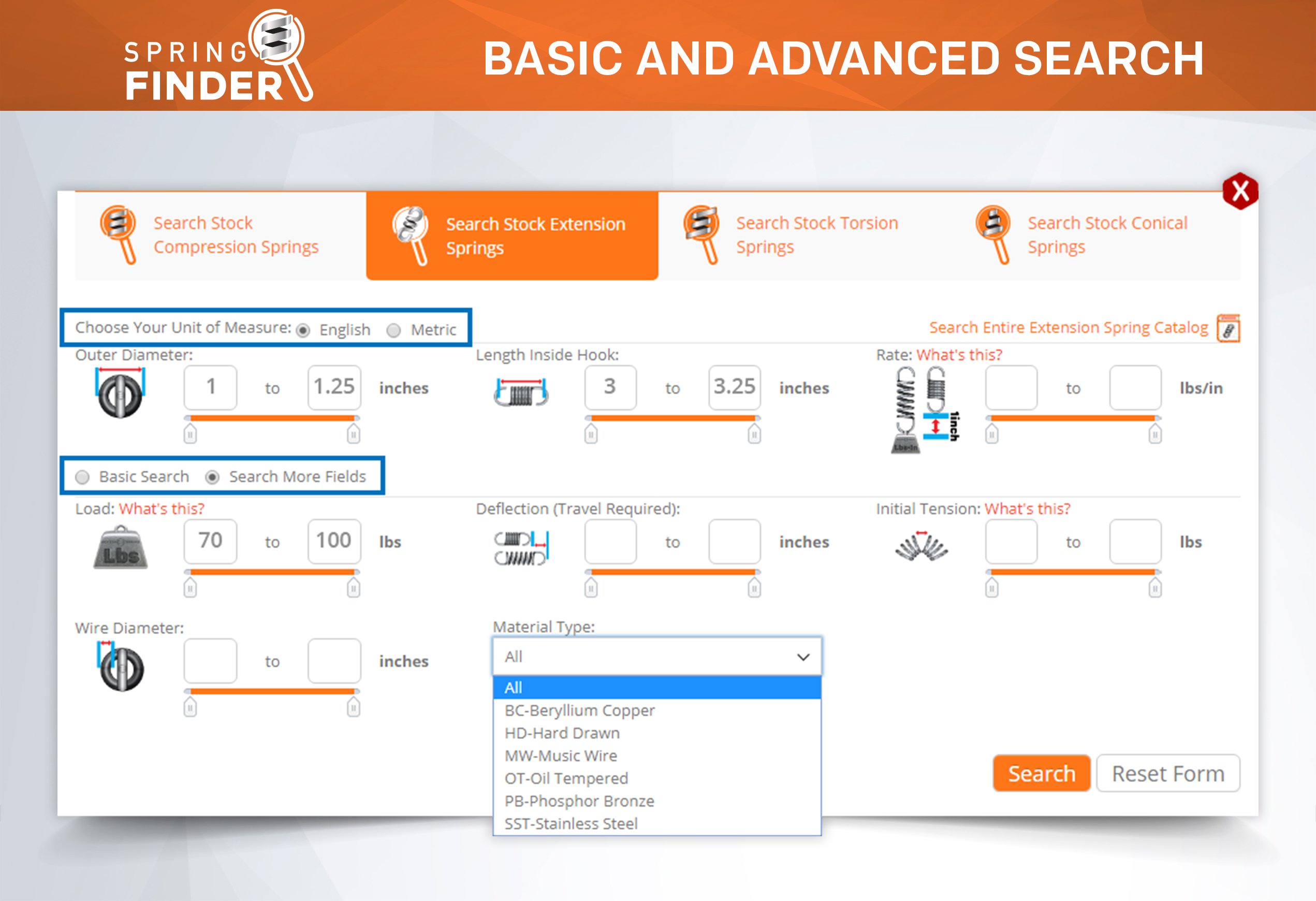

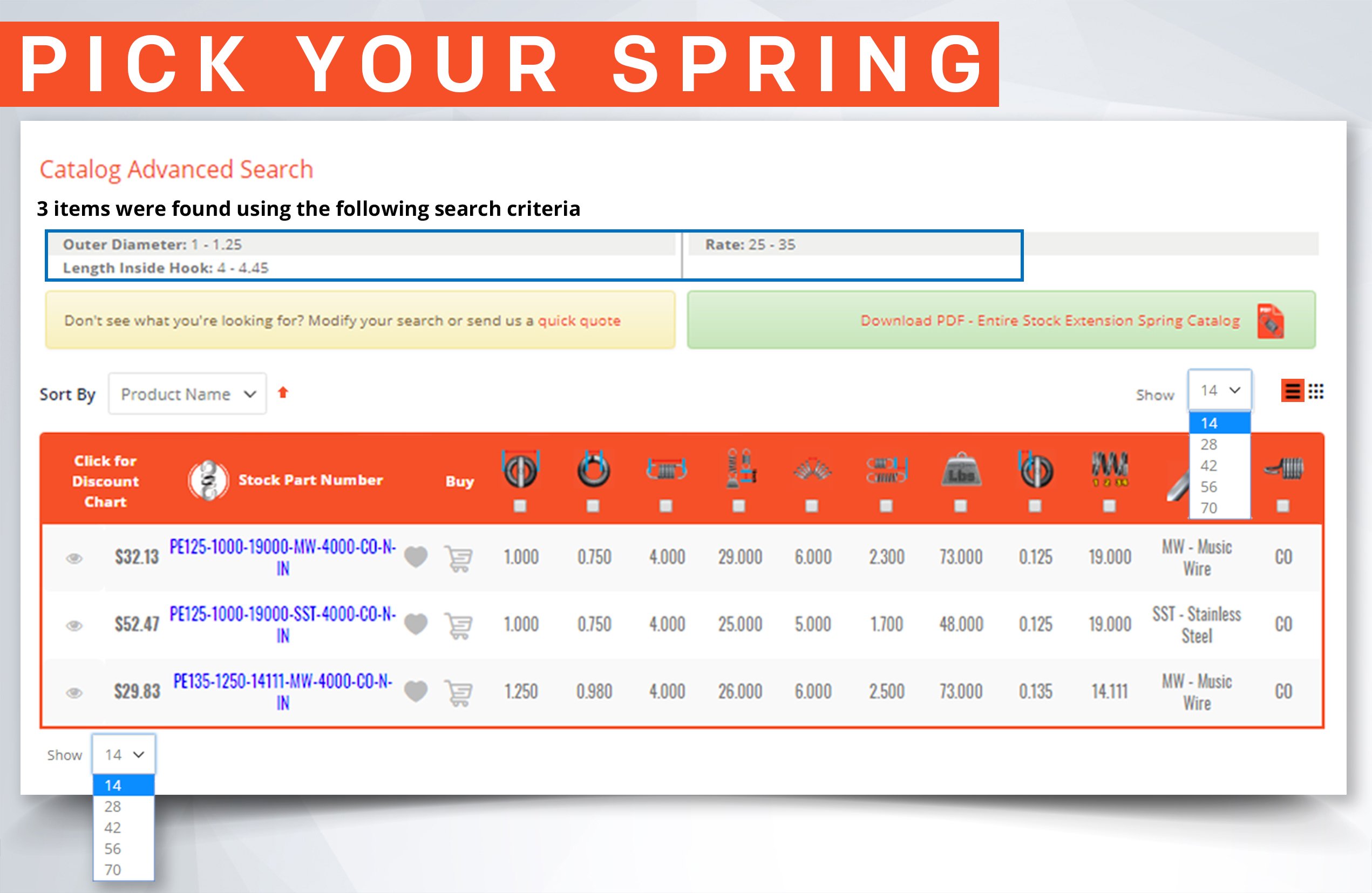

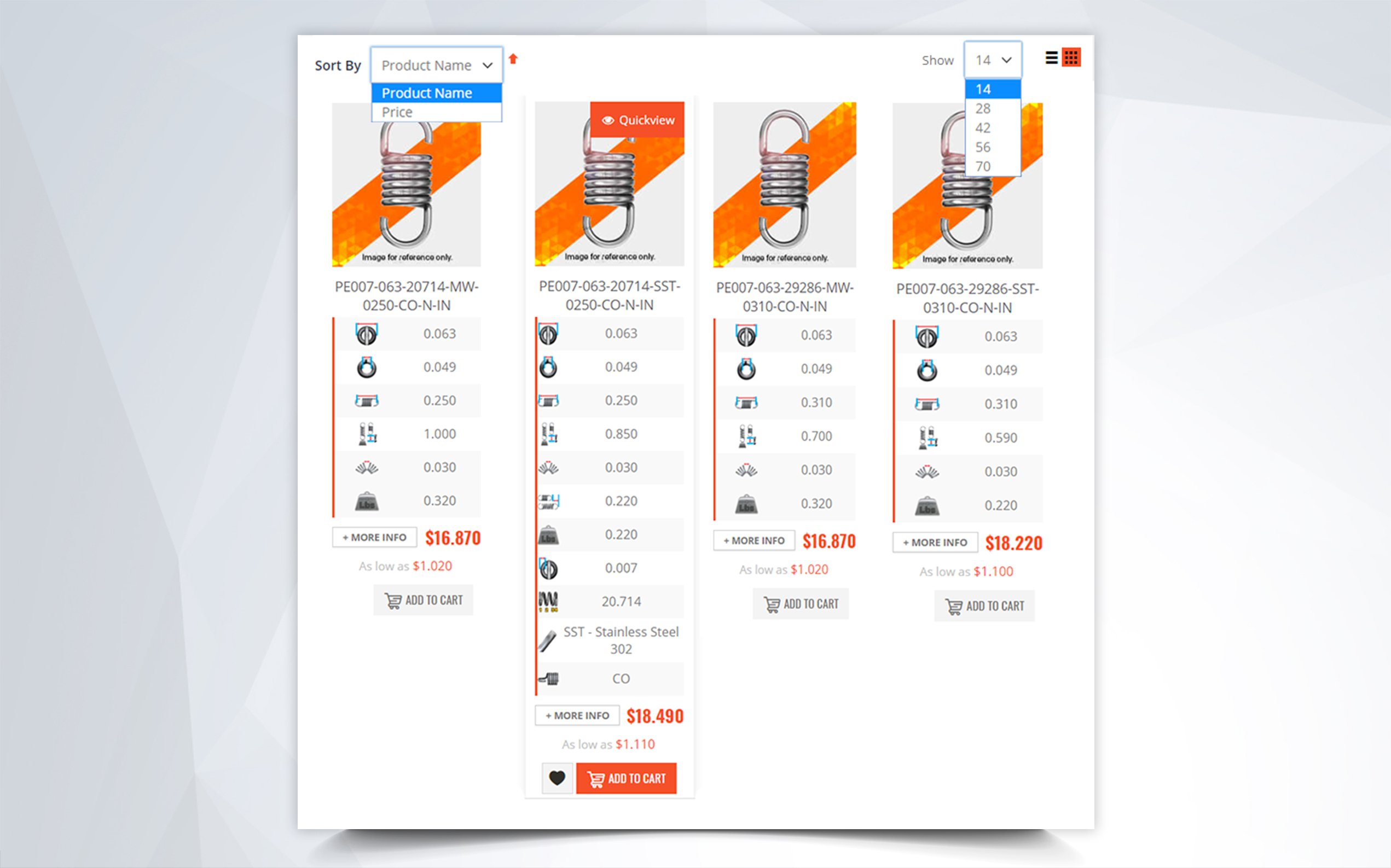

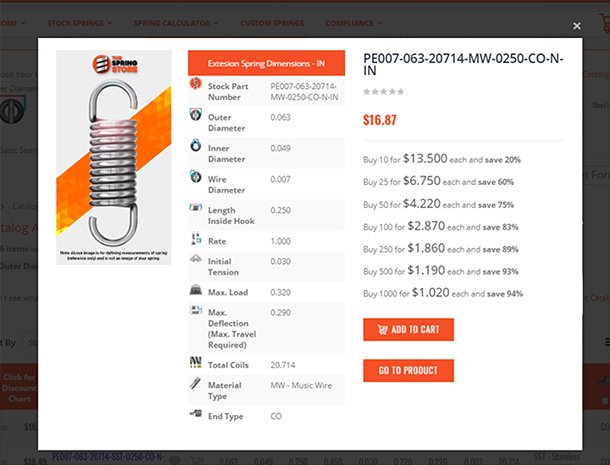

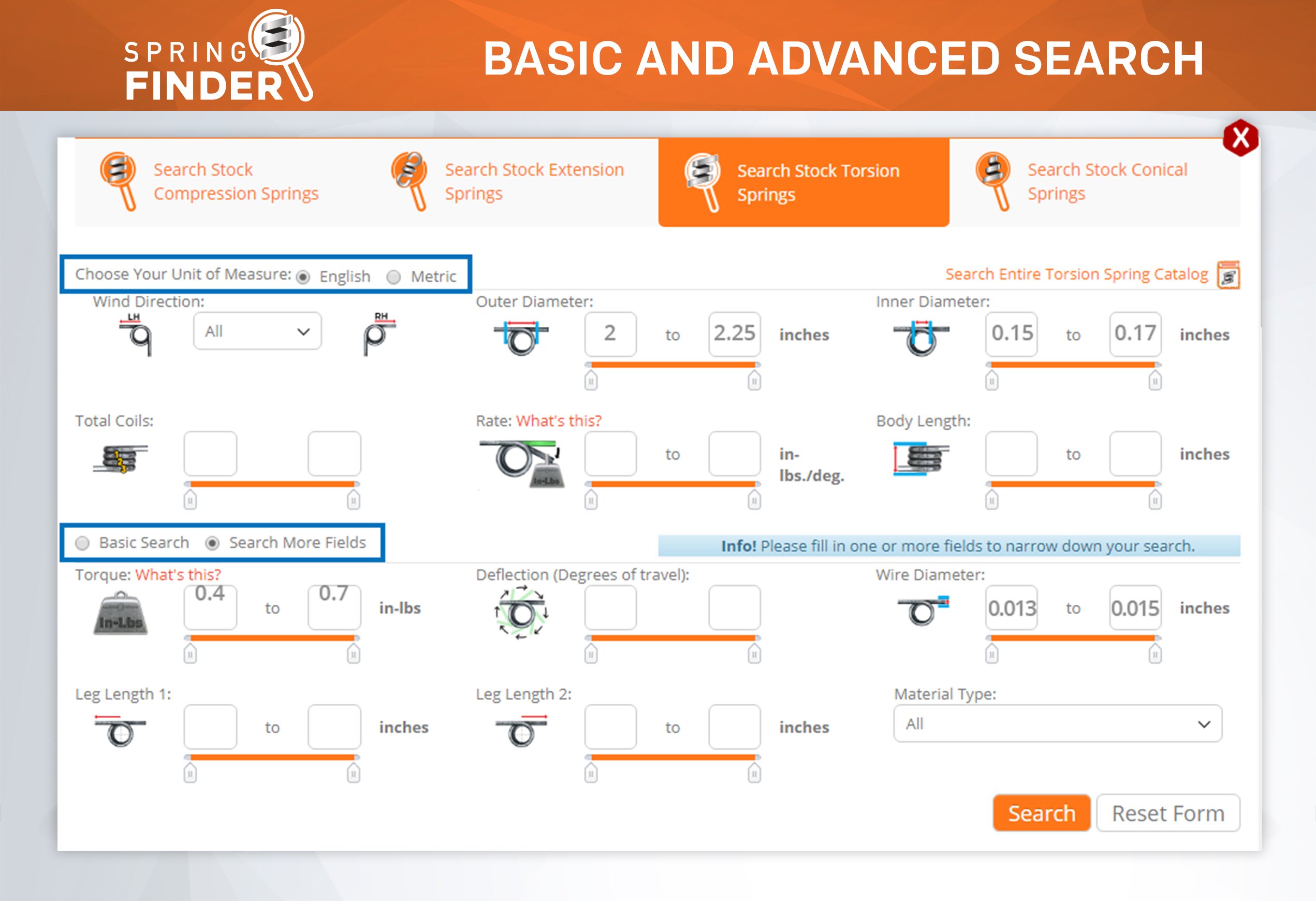

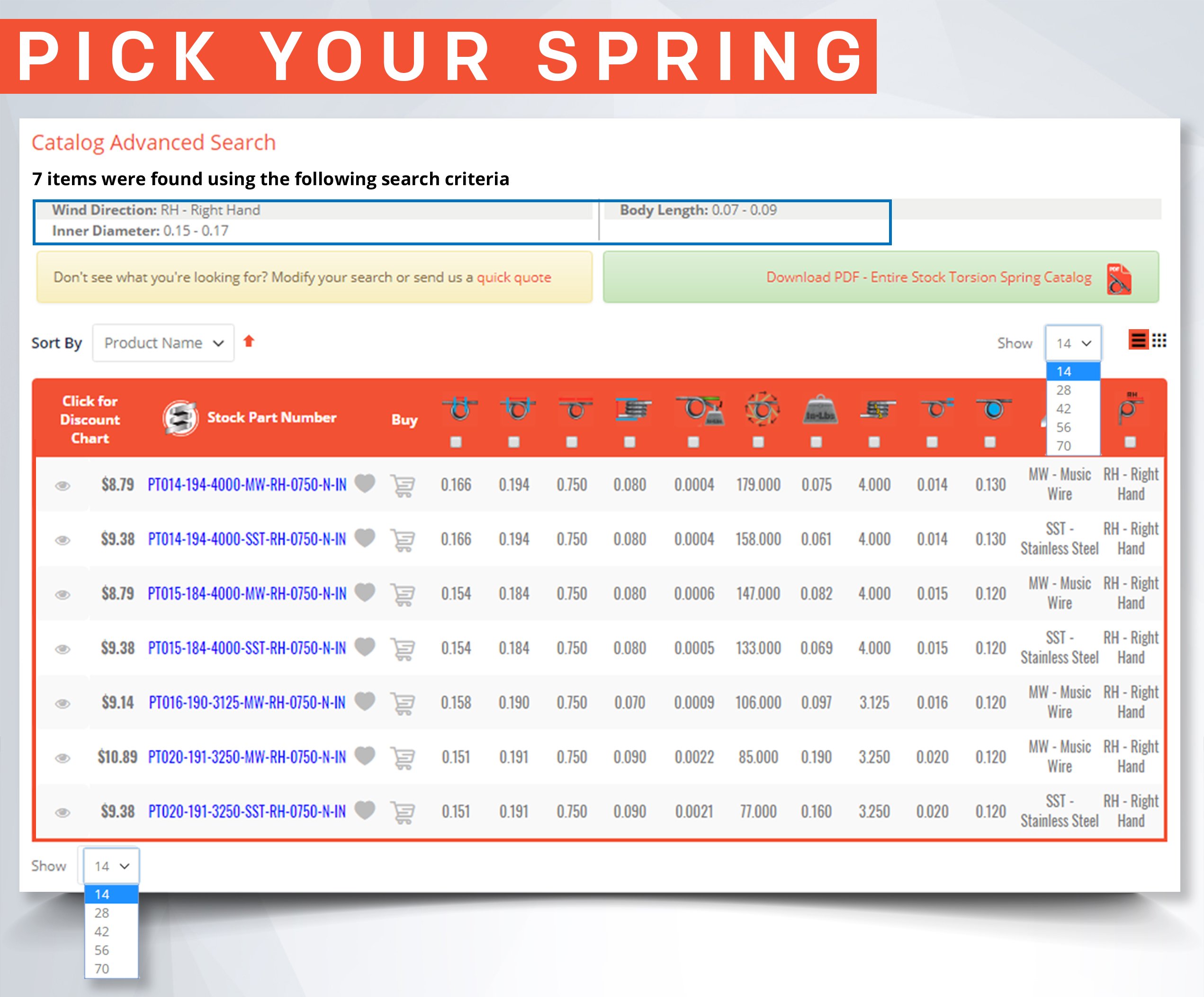

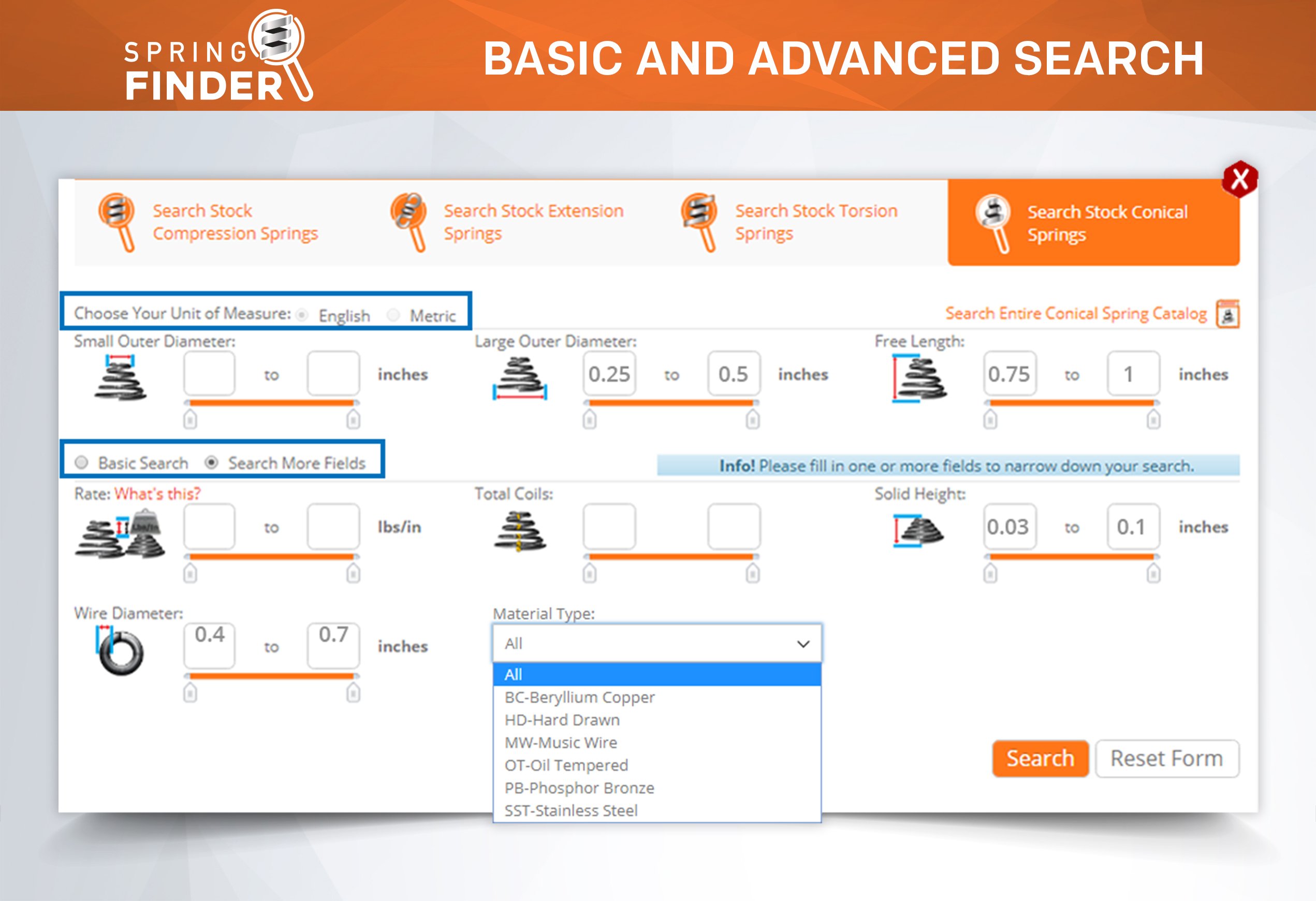

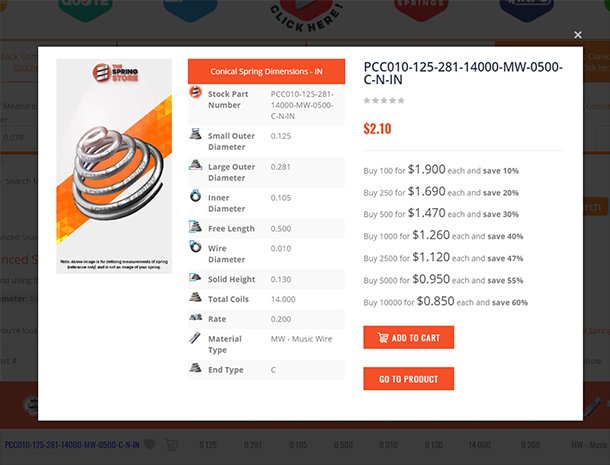

The base of spring design is knowing the limitations on the spring dimensions based on the spring’s surroundings. This applies to dimensions like inner diameter, outer diameter, free length (compression springs), body length (torsional springs), and length inside hooks (extension springs). Another factor that must be noted is the material type since some springs might be placed in a device where they might have to resist either high temperatures or corrosive environments.

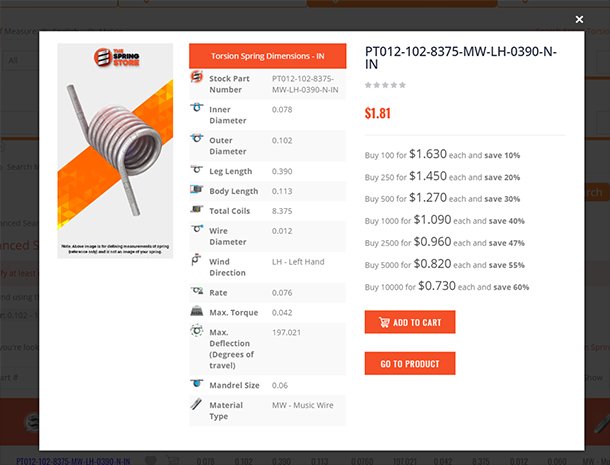

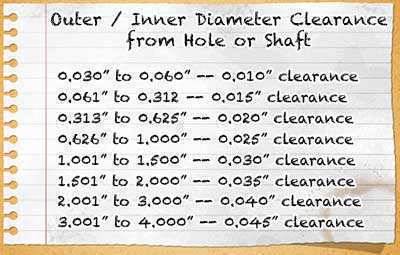

Outer Diameter / Inner Diameter:

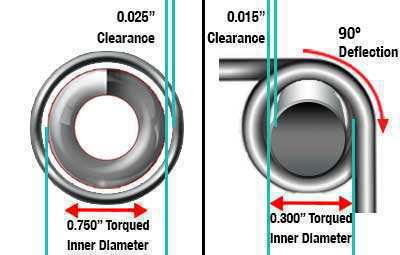

Outer diameter is the width of your spring measured from outside the coils. If your compression or extension spring is going to be installed inside a hole, you wanna make sure that the outer diameter isn’t too tight or too loose inside the orifice. In the case of a torsional spring, it usually doesn’t go inside a hole but the distance between the spring and its surroundings is also important to know. The clearance needed between the spring and the hole walls depends on the size of the the spring. This is due to the fact that a compression spring’s outer diameter expands a little when it is compressed. This happens especially if you exceed the suggested maximum deflection. The tables explaining the clearance needed for both outer and inner diameter is to your right as it is also shown below.

Outer / Inner Diameter Clearance from Hole or Shaft

Inner diameter is the width of a spring measured from the inside of the coils. This dimension’s tolerancing is only required for compression or torsion springs since extension springs don’t go over shafts. In the case of a compression spring, you must make sure that its inner diameter won’t be too tight or loose around the shaft. In the case of a torsional spring, since its inner diameter contracts (shrinks) when the spring is torqued, you must make sure that the contracted inner diameter won’t be too tight around the shaft so you will have to base the shaft clearance on the already torqued inner diameter.

Free Length (Compression):

Free length is the height of a spring in its free, unloaded state. In some cases, the free length of a compression spring can be easily adjusted when you’re in need to meet a certain working load. If you’re not able to meet the amount of travel under the required load, you may either make the free length longer for more travel thus more force, or make the free length shorter for less travel thus less force. If the spring is too short and you have minimal travel from the original length, making it shorter will reduce that travel to a more minimal amount. The dimensioning and tolerancing in this case is up to the customer to decide since it depends on the specific working loads they are required to meet.

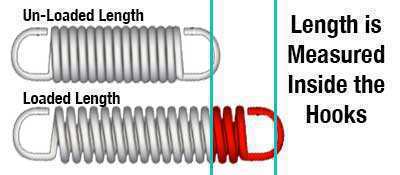

Length Inside Hooks (Extension):

Length inside hooks is the longitude of an extension spring which includes the body length and hook gaps. Making adjustments to the length inside hooks is a bit more delicate than adjusting a compression spring’s length. Extension springs are usually pre-loaded when installed so that they stay in place so the length inside hooks cannot be longer than the space between the handles or posts where it will be connected. When dimensioning and tolerancing your extension spring, you want to make sure that, even with the tolerances, the spring will still be able to pre-load.

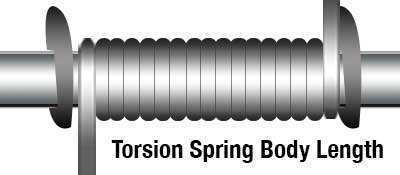

Body Length (Torsional):

Body length is the total length of a torsion spring’s coils piled together. Since torsional springs go over a shaft or mandrel, you have to make sure that the body length isn’t too long to fit in the designated space where the torsional spring shall be installed. In this case, when dimensioning and tolerancing

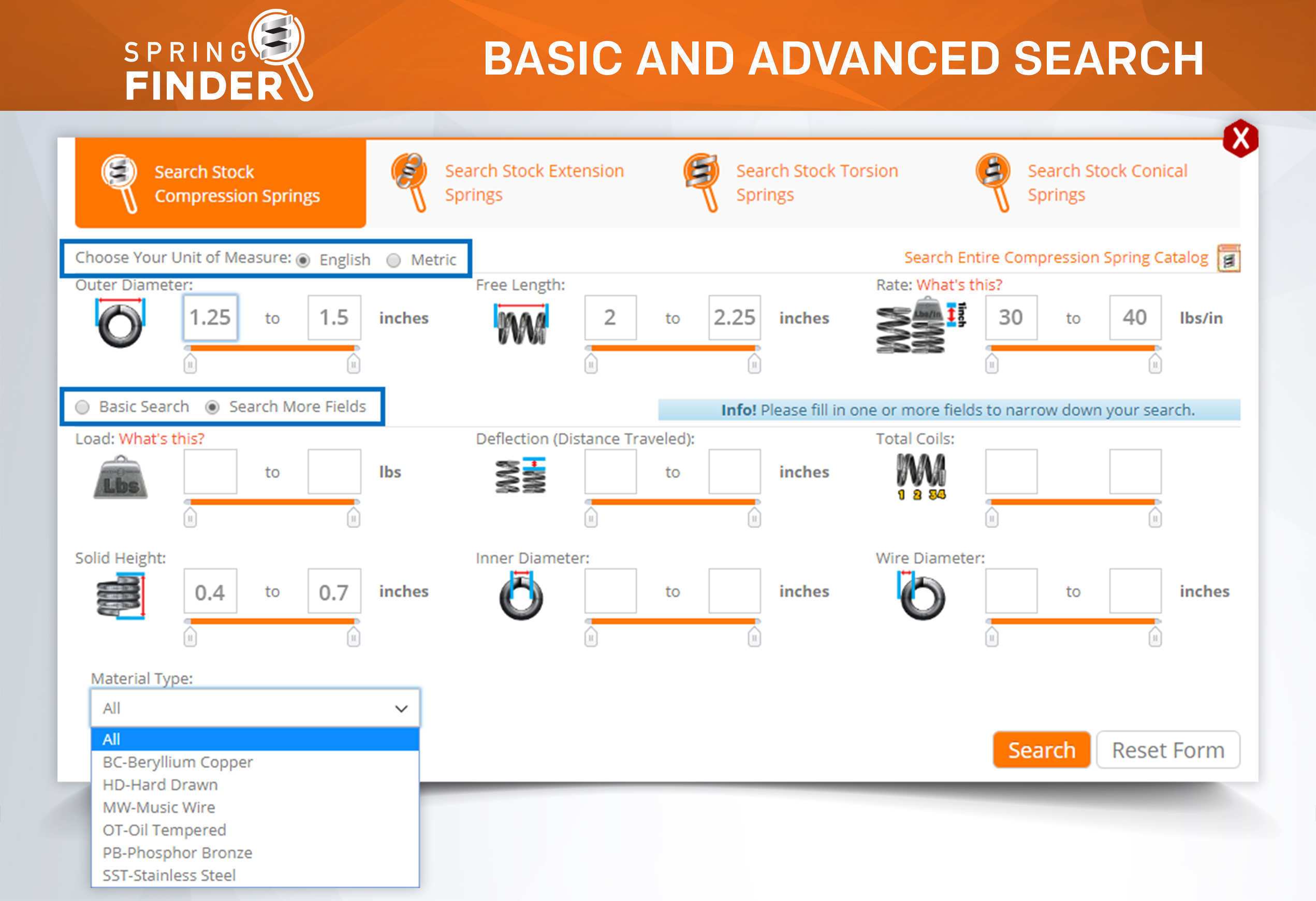

Material Type:

Selecting the material type for your spring is a highly important task. The most commonly used material type is Music Wire ASTM A228. This material type is also the most economical. There are other material types which might be used for high temperatures, corrosive environments, or are to be used in an area where they must be non-magnetic. The material types we use at The Spring Store by Acxess Spring include: Music Wire ASTM A228, Oil Tempered MB A229, Carbon Valve A230, Hard Drawn ASTM A227, Stainless Steel 17-7 A313, Stainless Steel 302 A313, Stainless Steel 316, Chrome Silicon A401, Phosphor Bronze Grade A B159, and Beryllium Copper B197. You can find the properties of these material types and more at our Properties of Common Spring Materials page.