Standard Spring Wire Diameter Sizes

Definition: Chart or table which shows the stock wire diameter sizes as well as the material type and other factors such as tensile strength. Great for picking what material type will do the job.

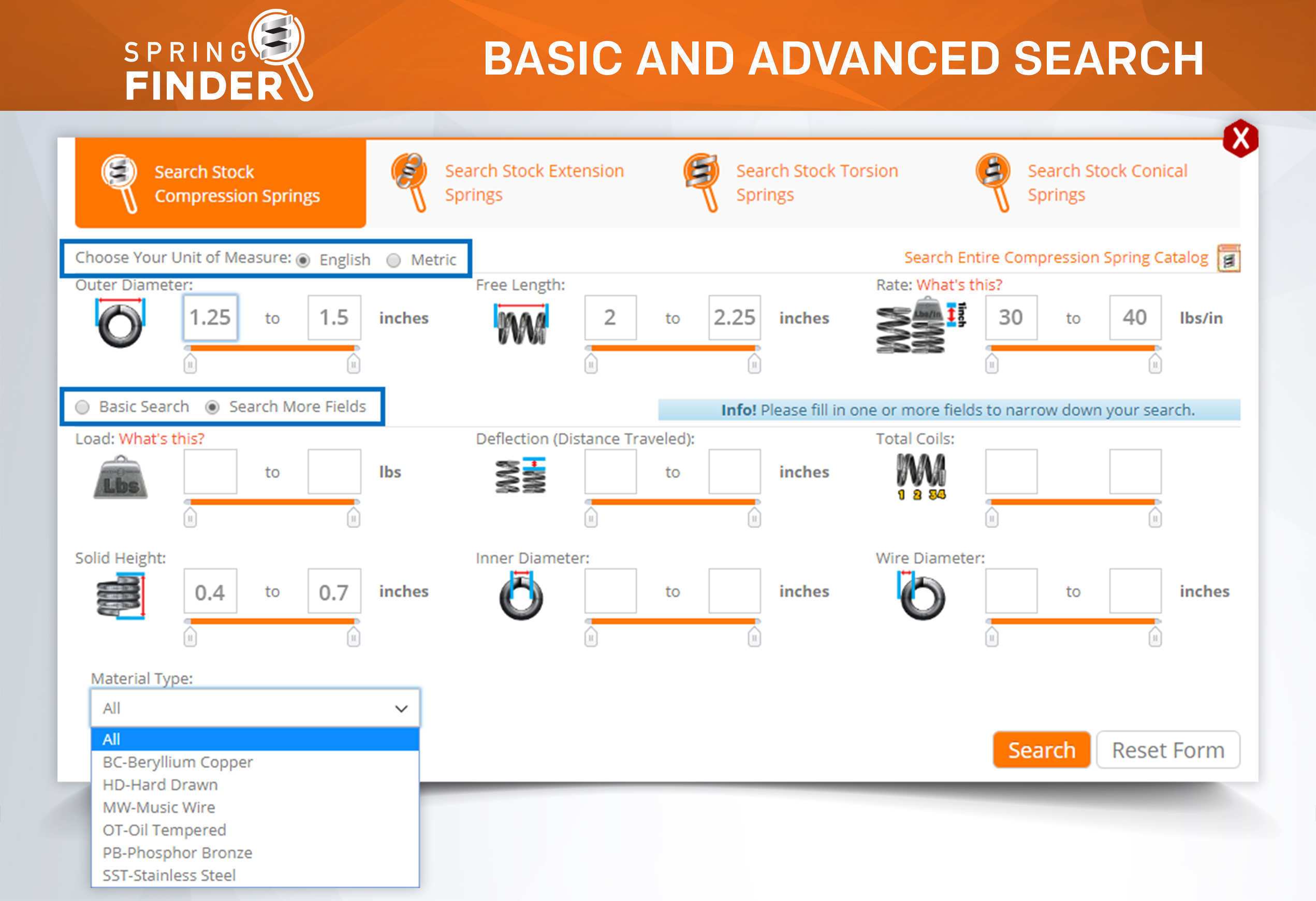

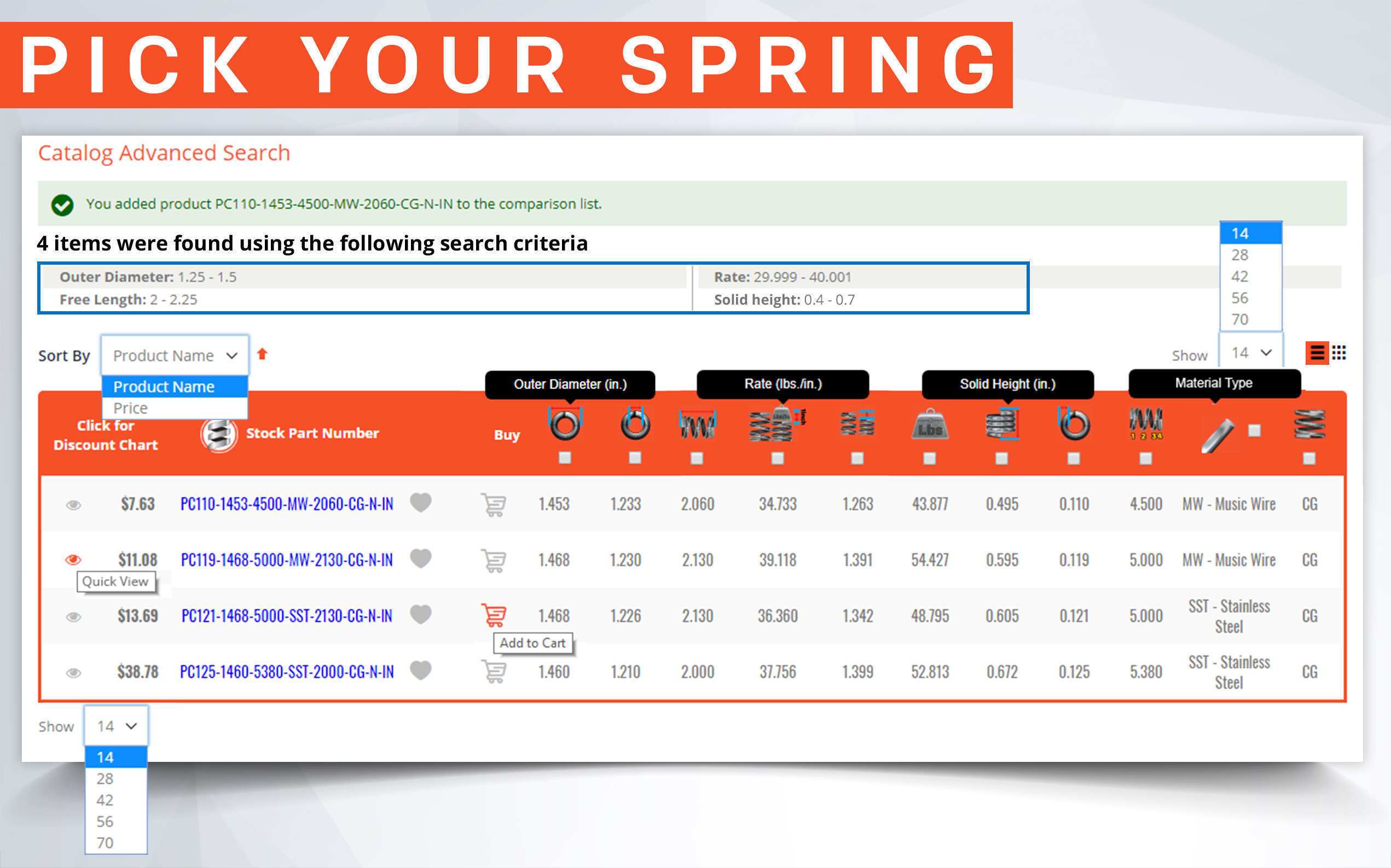

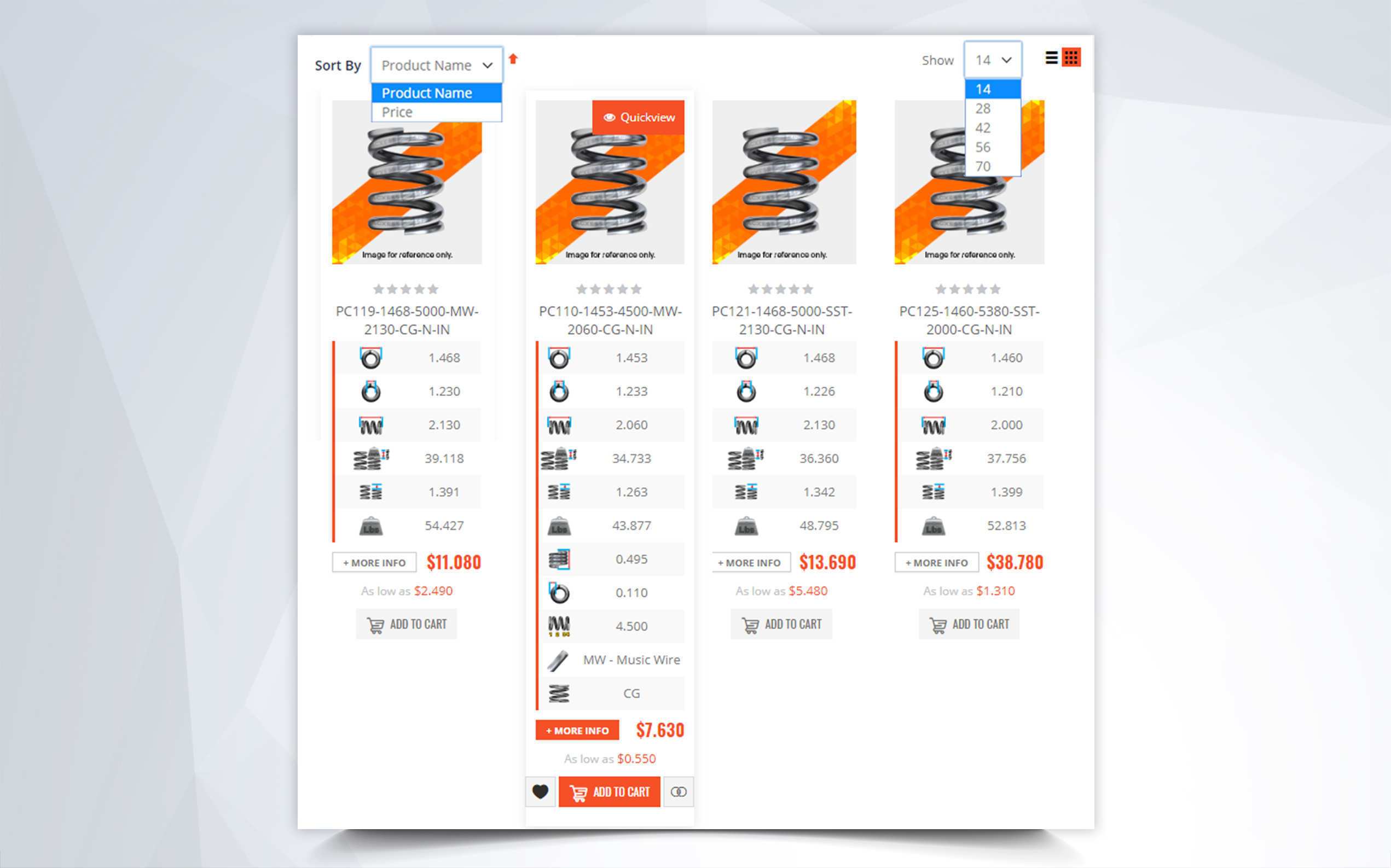

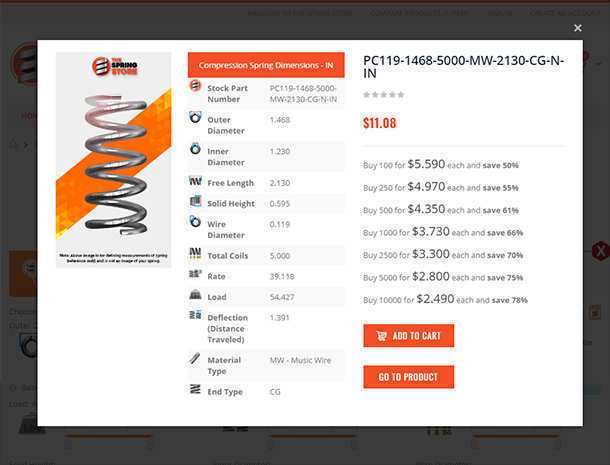

Selecting a wire diameter for a spring as well as what material type that wire will be made of is no easy task. When designing a spring not only are you looking for it to fit your device but you’re also looking for it to meet certain load and travel requirements as well as environmental requirements. In this article we will show you what each wire diameter is good for as well as how changing the wire diameter or the material type will affect your spring’s force and elasticity.

The information provided on material types includes the temperatures your spring is able to resist as well as the components that make up that specific material type and an approximate rockwell hardness. The rockwell hardness of a spring wire defines how hard the material is. This doesn't mean it defines the strength, it simply shows how flexible or how brittle the spring wire may be. The rockwell hardness of a certain wire diameter is measured using a rockwell tester through the process of indentation hardness of a material by applying a large amount of load on the wire and noting the depth of penetration.

| Wire Diameter in English Units (inches) | Wire Diameter in Metric Units (millimeters) |

| 0.008" | 0.203 mm |

| 0.009" | 0.229 mm |

| 0.010" | 0.254 mm |

| 0.011" | 0.279 mm |

| 0.012" | 0.305 mm |

| 0.013" | 0.330 mm |

| 0.014" | 0.356 mm |

| 0.015" | 0.381 mm |

| 0.016" | 0.406 mm |

| 0.017" | 0.432 mm |

| 0.018" | 0.457 mm |

| 0.019" | 0.483 mm |

| 0.020" | 0.508 mm |

| 0.021" | 0.533 mm |

| 0.022" | 0.559 mm |

| 0.023" | 0.584 mm |

| 0.024" | 0.610 mm |

| 0.025" | 0.635 mm |

| 0.026" | 0.660 mm |

| 0.027" | 0.686 mm |

| 0.028" | 0.711 mm |

| 0.029" | 0.737 mm |

| 0.030" | 0.762 mm |

| 0.031" | 0.787 mm |

| 0.032" | 0.813 mm |

| 0.033" | 0.838 mm |

| 0.034" | 0.864 mm |

| 0.035" | 0.889 mm |

| 0.036" | 0.914 mm |

| 0.037" | 0.940 mm |

| 0.038" | 0.965 mm |

| 0.039" | 0.991 mm |

| 0.040" | 1.016 mm |

| 0.041" | 1.041 mm |

| 0.042" | 1.067 mm |

| 0.043" | 1.092 mm |

| 0.044" | 1.118 mm |

| 0.045" | 1.143 mm |

| 0.046" | 1.168 mm |

| 0.047" | 1.194 mm |

| 0.048" | 1.219 mm |

| 0.049" | 1.225 mm |

| 0.050" | 1.270 mm |

| 0.051" | 1.296 mm |

| 0.052" | 1.321 mm |

| 0.053" | 1.346 mm |

| 0.054" | 1.372 mm |

| 0.055" | 1.397 mm |

| 0.056" | 1.422 mm |

| 0.057" | 1.448 mm |

| 0.058" | 1.473 mm |

| 0.059" | 1.499 mm |

| 0.060" | 1.524 mm |

| 0.061" | 1.549 mm |

| 0.0625" | 1.588 mm |

| 0.063" | 1.600 mm |

| 0.064" | 1.626 mm |

| 0.065" | 1.651 mm |

| 0.066" | 1.676 mm |

| 0.067" | 1.702 mm |

| 0.068" | 1.727 mm |

| 0.070" | 1.778 mm |

| 0.071" | 1.803 mm |

| 0.072" | 1.829 mm |

| 0.073" | 1.854 mm |

| 0.074" | 1.880 mm |

| 0.075" | 1.905 mm |

| 0.076" | 1.930 mm |

| 0.078" | 1.981 mm |

| 0.079" | 2.007 mm |

| 0.080" | 2.032 mm |

| 0.081" | 2.057 mm |

| 0.082" | 2.083 mm |

| 0.083" | 2.108 mm |

| 0.084" | 2.134 mm |

| 0.085" | 2.159 mm |

| 0.086" | 2.184 mm |

| 0.087" | 2.210 mm |

| 0.088" | 2.235 mm |

| 0.089" | 2.261 mm |

| 0.090" | 2.286 mm |

| 0.091" | 2.311 mm |

| 0.092" | 2.337 mm |

| 0.093" | 2.362 mm |

| 0.094" | 2.388 mm |

| 0.095" | 2.413 mm |

| 0.097" | 2.464 mm |

| 0.098" | 2.489 mm |

| 0.099" | 2.515 mm |

| 0.100" | 2.540 mm |

| 0.101" | 2.565 mm |

| 0.102" | 2.591 mm |

| 0.103" | 2.616 mm |

| 0.105" | 2.667 mm |

| 0.106" | 2.692 mm |

| 0.109" | 2.769 mm |

| 0.110" | 2.794 mm |

| 0.112" | 2.845 mm |

| 0.113" | 2.870 mm |

| 0.114" | 2.896 mm |

| 0.115" | 2.921 mm |

| 0.116" | 2.946 mm |

| 0.117" | 2.972 mm |

| 0.118" | 2.997 mm |

| 0.119" | 3.023 mm |

| 0.120" | 3.048 mm |

| 0.121" | 3.073 mm |

| 0.122" | 3.099 mm |

| 0.123" | 3.124 mm |

| 0.124" | 3.150 mm |

| 0.125" | 3.175 mm |

| 0.126" | 3.200 mm |

| 0.127" | 3.226 mm |

| 0.128" | 3.251 mm |

| 0.130" | 3.302 mm |

| 0.132" | 3.353 mm |

| 0.133" | 3.378 mm |

| 0.134" | 3.404 mm |

| 0.135" | 3.429 mm |

| 0.136" | 3.454 mm |

| 0.140" | 3.556 mm |

| 0.141" | 3.581 mm |

| 0.142" | 3.607 mm |

| 0.145" | 3.683 mm |

| 0.146" | 3.708 mm |

| 0.147" | 3.734 mm |

| 0.148" | 3.759 mm |

| 0.149" | 3.785 mm |

| 0.150" | 3.810 mm |

| 0.152" | 3.861 mm |

| 0.156" | 3.962 mm |

| 0.159" | 4.039 mm |

| 0.160" | 4.064 mm |

| 0.162" | 4.115 mm |

| 0.163" | 4.140 mm |

| 0.165" | 4.191 mm |

| 0.167" | 4.242 mm |

| 0.170" | 4.318 mm |

| 0.172" | 4.369 mm |

| 0.177" | 4.496 mm |

| 0.180" | 4.572 mm |

| 0.182" | 4.623 mm |

| 0.186" | 4.724 mm |

| 0.187" | 4.750 mm |

| 0.188" | 4.775 mm |

| 0.190" | 4.826 mm |

| 0.191" | 4.851 mm |

| 0.192" | 4.877 mm |

| 0.193" | 4.902 mm |

| 0.196" | 4.978 mm |

| 0.206" | 5.232 mm |

| 0.207" | 5.258 mm |

| 0.217" | 5.512 mm |

| 0.218" | 5.537 mm |

| 0.220" | 5.588 mm |

| 0.225" | 5.715 mm |

| 0.234" | 5.943 mm |

| 0.235" | 5.969 mm |

| 0.245" | 6.223 mm |

| 0.247" | 6.274 mm |

| 0.250" | 6.350 mm |

| 0.262" | 6.655 mm |

| 0.264" | 6.706 mm |

| 0.281" | 7.137 mm |

| 0.282" | 7.163 mm |

| 0.283" | 7.188 mm |

| 0.312" | 7.925 mm |

| 0.343" | 8.712 mm |

| 0.362" | 9.195 mm |

| 0.375" | 9.525 mm |

| 0.394" | 10.008 mm |

| 0.437" | 11.100 mm |

| 0.453" | 11.506 mm |

| 0.468" | 11.887 mm |

| 0.500" | 12.700 mm |

| 0.562" | 14.275 mm |

| 0.625" | 15.875 mm |

![]()

| Wire Diameter in English Units (inches) | Wire Diameter in Metric Units (millimeters) |

| 0.080" | 2.032 mm |

| 0.091" | 2.311 mm |

| 0.098" | 2.489 mm |

| 0.105" | 2.667 mm |

| 0.118" | 2.997 mm |

| 0.125" | 3.175 mm |

| 0.135" | 3.429 mm |

| 0.148" | 3.759 mm |

| 0.156" | 3.962 mm |

| 0.162" | 4.115 mm |

| 0.172" | 4.369 mm |

| 0.187" | 4.750 mm |

| 0.207" | 5.258 mm |

| 0.225" | 5.715 mm |

| 0.234" | 5.943 mm |

| 0.250" | 6.350 mm |

| 0.262" | 6.655 mm |

| 0.281" | 7.137 mm |

| 0.312" | 7.925 mm |

| 0.343" | 8.712 mm |

| 0.375" | 9.525 mm |

| 0.394" | 10.008 mm |

| 0.406" | 10.312 mm |

| 0.437" | 11.100 mm |

| 0.453" | 11.506 mm |

| 0.468" | 11.887 mm |

| 0.500" | 12.700 mm |

| 0.532" | 13.513 mm |

| 0.562" | 14.275 mm |

| 0.625" | 15.875 mm |

AISI 5160H Steel

| Rod Diameter in English Units (inches) | Rod Diameter in Metric Units (millimeters) |

| 0.687" | 17.450 mm |

| 0.750" | 19.050 mm |

| 0.813" | 20.650 mm |

| 0.875" | 22.225 mm |

| 0.937" | 23.800 mm |

| 1.000" | 25.400 mm |

High Carbon Spring Wire

High carbon spring wire includes Music Wire ASTM A228(also known as Spring Steel) and Hard Drawn ASTM A227. These material types are made from different portions of Carbon (C) and Manganese (Mn). Their rockwell hardness may vary between C31 and C60 depending on the high carbon spring wire type and the formula in which the material type is made. Their maximum temperatures are of 250ºF (121ºC).

-Music Wire ASTM A228 (Phosphate Coated)

It is cold drawn and has a high and uniform tensile strength. It will make high quality springs and wire forms.

-Hard Drawn ASTM A227 (MB Spring Wire Class 1)

It is cold Drawn and has average stress applications. You will get a lower cost springs and wire forms.

Alloy Steel Wire

In the category of alloy steel wire is Chrome Silicon ASTM A401. It is made from Carbon (C), Chromium (Cr), and Silicon (Si). The rockwell hardness of this alloy steel wire may vary from C48 to C55 depending on how it was made. The maximum temperature this material type is able to withstand is of 475ºF (246ºC).

-Chrome Silicon ASTM A401

It is cold drawn and heat treated before manufacturing and it is commonly used for shock loads and average elevated temperatures.

Stainless Steel Wire

Stainless steel material types include Stainless Steel 302 (304) ASTM A313, Stainless Steel 316 ASTM A313 (631), and Stainless Steel 17-7 PH ASTM A313 (631). Both Stainless Steel 302 and Stainless Steel 17-7 are made from Chromium (Cr) and Nickel (Ni) while Stainless Steel 316 includes an additional ingredient which is Molybdenum (Mo). The rockwell hardness of these stainless steel wires varies from a minimum of C35 to a maximum of C57. The most temperature these springs are able to withstand is 550ºF (288ºC) for Stainless Steel 302 and Stainless Steel 316. Stainless Steel 17-7 is able to resist a temperature of 650ºF (343ºC).

-Stainless Steel 302/304 ASTM A313

This material type is cold drawn, for general purposes, and resistant to corrosion and high temperatures. It is magnetic in spring temper.

-Stainless Steel 316 ASTM A313 (631)

This type of stainless steel is the same as Stainless Steel 302 except it is more resistant to corrosive environments. It is also 90% non-magnetic.

-Stainless Steel 17-7 PH ASTM A313 (631)

It is cold drawn and precipitation hardened after being manufactured. Very strong and servers for general purpose corrosion resistance. It is slightly magnetic in spring temper.

Non-Ferrous Alloy Wire

In this section we include Phosphor Bronze ASTM B159 and Beryllium Copper ASTM B197. These non-ferrous alloy wires are made from Copper (Cu) and Beryllium(Be). Their rockwell hardness may range from C35 to C104. The maximum temperatures these wire diameters are able to resist are different from each other where Phosphor Bronze is able to resist 200ºF (93.8ºC) and Beryllium Copper is able to resist 400ºF(204ºC).

-Phosphor Bronze

It is cold drawn and good for corrosive environments as well as electrical conductivity.

-Beryllium Copper

-It is also cold drawn and may be mill hardened before manufacturing. Corrosion resistant as well as electrically conductive. This material type has high physicals.

|

Wire Diameter in English Units (inches) |

Wire Diameter in Metric Units (millimeters) |

| 0.008" | 0.203 mm |

| 0.009" | 0.229 mm |

| 0.010" | 0.254 mm |

| 0.011" | 0.279 mm |

| 0.012" | 0.305 mm |

| 0.013" | 0.330 mm |

| 0.014" | 0.356 mm |

| 0.015" | 0.381 mm |

| 0.016" | 0.406 mm |

| 0.017" | 0.432 mm |

| 0.018" | 0.457 mm |

| 0.019" | 0.483 mm |

| 0.020" | 0.508 mm |

| 0.021" | 0.533 mm |

| 0.022" | 0.559 mm |

| 0.023" | 0.584 mm |

| 0.024" | 0.610 mm |

| 0.025" | 0.635 mm |

| 0.026" | 0.660 mm |

| 0.027" | 0.686 mm |

| 0.028" | 0.711 mm |

| 0.029" | 0.737 mm |

| 0.030" | 0.762 mm |

| 0.031" | 0.787 mm |

| 0.032" | 0.813 mm |

| 0.033" | 0.838 mm |

| 0.034" | 0.864 mm |

| 0.035" | 0.889 mm |

| 0.036" | 0.914 mm |

| 0.037" | 0.940 mm |

| 0.038" | 0.965 mm |

| 0.039" | 0.991 mm |

| 0.040" | 1.016 mm |

| 0.041" | 1.041 mm |

| 0.042" | 1.067 mm |

| 0.043" | 1.092 mm |

| 0.044" | 1.118 mm |

| 0.045" | 1.143 mm |

| 0.046" | 1.168 mm |

| 0.047" | 1.194 mm |

| 0.048" | 1.219 mm |

| 0.049" | 1.225 mm |

| 0.050" | 1.270 mm |

| 0.051" | 1.296 mm |

| 0.052" | 1.321 mm |

| 0.053" | 1.346 mm |

| 0.054" | 1.372 mm |

| 0.055" | 1.397 mm |

| 0.056" | 1.422 mm |

| 0.057" | 1.448 mm |

| 0.058" | 1.473 mm |

| 0.059" | 1.499 mm |

| 0.060" | 1.524 mm |

| 0.061" | 1.549 mm |

| 0.0625" | 1.588 mm |

| 0.063" | 1.600 mm |

| 0.064" | 1.626 mm |

| 0.065" | 1.651 mm |

| 0.066" | 1.676 mm |

| 0.067" | 1.702 mm |

| 0.068" | 1.727 mm |

| 0.070" | 1.778 mm |

| 0.071" | 1.803 mm |

| 0.072" | 1.829 mm |

| 0.073" | 1.854 mm |

| 0.074" | 1.880 mm |

| 0.075" | 1.905 mm |

| 0.076" | 1.930 mm |

| 0.078" | 1.981 mm |

| 0.079" | 2.007 mm |

| 0.080" | 2.032 mm |

| 0.081" | 2.057 mm |

| 0.082" | 2.083 mm |

| 0.083" | 2.108 mm |

| 0.084" | 2.134 mm |

| 0.085" | 2.159 mm |

| 0.086" | 2.184 mm |

| 0.087" | 2.210 mm |

| 0.088" | 2.235 mm |

| 0.089" | 2.261 mm |

| 0.090" | 2.286 mm |

| 0.091" | 2.311 mm |

| 0.092" | 2.337 mm |

| 0.093" | 2.362 mm |

| 0.094" | 2.388 mm |

| 0.095" | 2.413 mm |

| 0.097" | 2.464 mm |

| 0.098" | 2.489 mm |

| 0.099" | 2.515 mm |

| 0.100" | 2.540 mm |

| 0.101" | 2.565 mm |

| 0.102" | 2.591 mm |

| 0.103" | 2.616 mm |

| 0.105" | 2.667 mm |

| 0.106" | 2.692 mm |

| 0.109" | 2.769 mm |

| 0.110" | 2.794 mm |

| 0.112" | 2.845 mm |

| 0.113" | 2.870 mm |

| 0.114" | 2.896 mm |

| 0.115" | 2.921 mm |

| 0.116" | 2.946 mm |

| 0.117" | 2.972 mm |

| 0.118" | 2.997 mm |

| 0.119" | 3.023 mm |

| 0.120" | 3.048 mm |

| 0.121" | 3.073 mm |

| 0.122" | 3.099 mm |

| 0.123" | 3.124 mm |

| 0.124" | 3.150 mm |

| 0.125" | 3.175 mm |

| 0.126" | 3.200 mm |

| 0.127" | 3.226 mm |

| 0.128" | 3.251 mm |

| 0.130" | 3.302 mm |

| 0.132" | 3.353 mm |

| 0.133" | 3.378 mm |

| 0.134" | 3.404 mm |

| 0.135" | 3.429 mm |

| 0.136" | 3.454 mm |

| 0.140" | 3.556 mm |

| 0.141" | 3.581 mm |

| 0.142" | 3.607 mm |

| 0.145" | 3.683 mm |

| 0.146" | 3.708 mm |

| 0.147" | 3.734 mm |

| 0.148" | 3.759 mm |

| 0.149" | 3.785 mm |

| 0.150" | 3.810 mm |

| 0.152" | 3.861 mm |

| 0.156" | 3.962 mm |

| 0.159" | 4.039 mm |

| 0.160" | 4.064 mm |

| 0.162" | 4.115 mm |

| 0.163" | 4.140 mm |

| 0.165" | 4.191 mm |

| 0.167" | 4.242 mm |

| 0.170" | 4.318 mm |

| 0.172" | 4.369 mm |

| 0.177" | 4.496 mm |

| 0.180" | 4.572 mm |

| 0.182" | 4.623 mm |

| 0.186" | 4.724 mm |

| 0.187" | 4.750 mm |

| 0.188" | 4.775 mm |

| 0.190" | 4.826 mm |

| 0.191" | 4.851 mm |

| 0.192" | 4.877 mm |

| 0.193" | 4.902 mm |

| 0.196" | 4.978 mm |

| 0.206" | 5.232 mm |

| 0.207" | 5.258 mm |

| 0.217" | 5.512 mm |

| 0.218" | 5.537 mm |

| 0.220" | 5.588 mm |

| 0.225" | 5.715 mm |

| 0.234" | 5.943 mm |

| 0.235" | 5.969 mm |

| 0.245" | 6.223 mm |

| 0.247" | 6.274 mm |

| 0.250" | 6.350 mm |

| 0.262" | 6.655 mm |

| 0.264" | 6.706 mm |

| 0.281" | 7.137 mm |

| 0.282" | 7.163 mm |

| 0.283" | 7.188 mm |

| 0.362" | 9.195 mm |

| 0.468" | 11.887 mm |

| 0.500" | 12.700 mm |

| 0.532" | 13.513 mm |

| 0.562" | 14.275 mm |

| 0.625" | 15.875 mm |