Hooke's Law for Torsion Springs

Introduction

Torsion springs, essential components in numerous mechanical applications, operate under the principles of Hooke's Law. This article explores its application in spring engineering, highlighting the role of advanced tools such as the Online Spring Force Tester and Spring Creator 5.0.

Fundamentals of Hooke's Law in Torsion Springs

Hooke's Law states that the torque in a torsion spring is proportional to the angle of torsion. This fundamental relationship, expressed as T = kθ, where T is the torque and θ is the angle of torsion, is essential for the design and analysis of these springs.

The Design of Torsion Springs

Effective design of torsion springs involves a deep understanding of the torsion constant and material properties. Engineers must consider factors like shear strength, elastic limits, and environmental conditions in which the spring will operate.

Online Spring Force Tester: Validation and Analysis

The use of the Online Spring Force Tester is crucial for validating torsion spring properties visually. This tool enables you to visually see the precise measurement of torque and deflection through a real time animation of your spring in motion, ensuring that the spring meets design specifications and maintains its integrity over its lifespan.

Spring Creator 5.0: Advances in Spring Design

Spring Creator 5.0 offers an innovative platform for designing and analyzing torsion springs. It provides detailed calculations and allows users to explore design variations, assessing how these changes affect spring performance.

Industrial Applications of Torsion Springs

Torsion springs are fundamental in sectors such as:

- Automotive: In components like clutches and suspension systems.

- Home Appliances: Key components in control mechanisms and door/window operations.

- Aerospace Industry: Where precision and reliability are paramount.

- Consumer Products: Such as toys and tools requiring return mechanisms or control.

Challenges in Torsion Spring Engineering

Challenges in torsion spring engineering include managing variable torques, fatigue resistance, and precision in manufacturing. The right selection of materials and the use of advanced technologies are key to addressing these challenges.

Materials in Spring Manufacturing

Material selection for torsion springs is a crucial aspect. Materials range from high-strength steels to specialized alloys, each with unique properties that affect spring performance.

Maintenance and Durability of Springs

Proper maintenance is key to the durability of torsion springs. Regular review and lubrication of the torsion springs over a shaft or pin to ensure a fatigue analysis. This helps prevent failures and extend their lifespan.

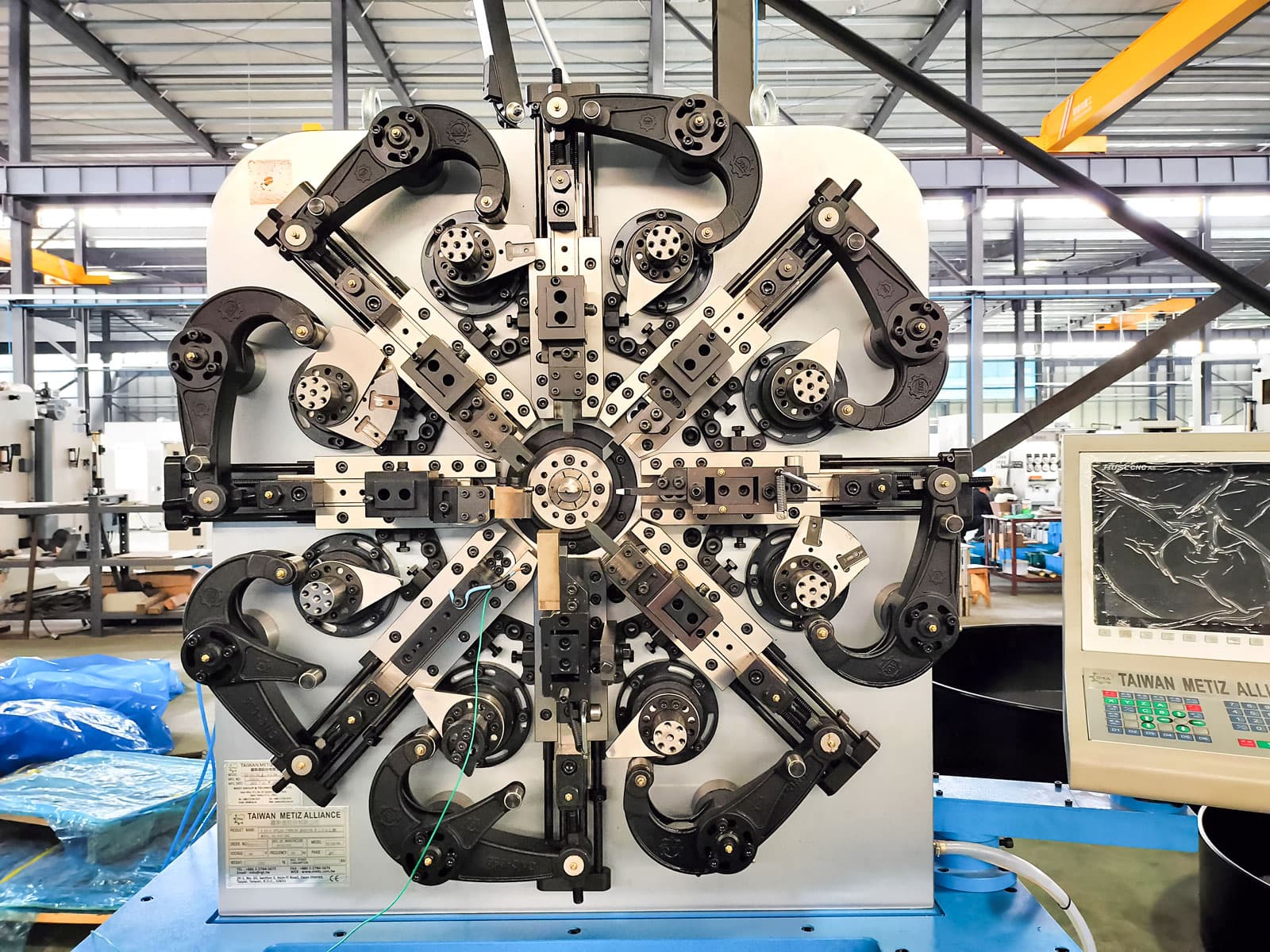

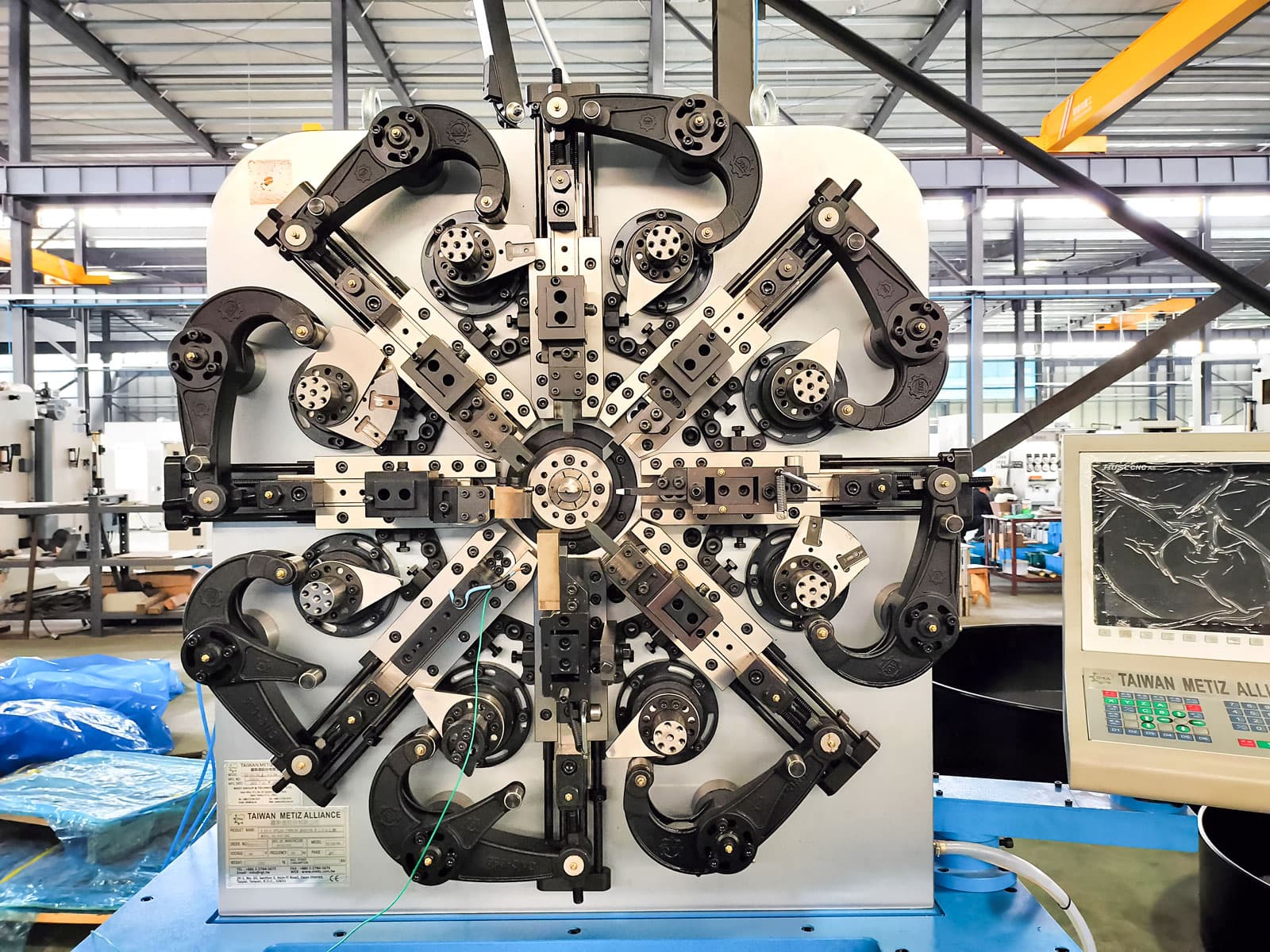

Advances in Manufacturing Techniques

Improvements in manufacturing techniques such as using CNC torsion spring making machines have enabled the production of more precise and resilient torsion springs. These advances facilitate the creation of springs that can withstand more extreme conditions and demanding load cycles.

Trends in Torsion Spring Engineering

Continuous innovation in torsion spring engineering points toward the development of lighter, stronger, and more efficient springs. The focus is on improving materials and manufacturing processes to meet the demands of evolving industries.

Conclusion

Hooke's Law is a cornerstone in understanding and designing torsion springs. Tools like Spring Creator 5.0 and the Online Spring Force Tester are essential for developing springs that not only meet technical standards but also offer superior performance across a variety of applications. The continuous evolution of materials and manufacturing technologies promises an exciting future in the field of torsion spring engineering.